-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 21, 2025 19:20 Back to list

Durable Hexagonal Gabions for Erosion Control & Retaining Walls

Understanding Hexagonal Gabion: An Essential Solution for Modern Engineering

In civil engineering and environmental protection, the demand for robust, flexible, and eco-friendly retaining structures and erosion control systems is ever-increasing. Among the most versatile solutions available is the Hexagonal Gabion. These wire mesh container111s, typically filled with rocks, offer unparalleled stability and permeability, making them indispensable for a wide array of projects. From riverbank stabilization to sophisticated architectural features, Hexagonal Gabion structures are recognized for their durability, cost-effectiveness, and minimal environmental footprint. This comprehensive guide delves into the technical intricacies, industry applications, and strategic advantages of this critical engineering component, providing insights for B2B decision-makers and technical professionals seeking reliable, long-term solutions.

The unique hexagonal weave pattern of the wire mesh provides exceptional tensile strength and flexibility, allowing the structure to deform without collapsing under dynamic loads, such as those caused by seismic activity or hydraulic pressures. This inherent adaptability is a key differentiator from rigid concrete structures. Our discussion will cover the evolution of gabion technology, its current market landscape, and future trends driven by global infrastructure development and climate change adaptation strategies. Understanding these elements is crucial for selecting the optimal gabion solution for diverse and challenging environmental conditions.

Industry Trends and Market Dynamics for Advanced Gabion Solutions

The global market for gabion solutions is experiencing significant growth, primarily fueled by increased investments in infrastructure development, rising concerns over soil erosion and natural disaster mitigation, and a growing emphasis on sustainable engineering practices. According to recent market analysis, the global gabion market is projected to reach approximately USD 1.2 billion by 2027, with a compound annual growth rate (CAGR) of 5.5% from 2020. This growth is particularly pronounced in regions susceptible to flooding, landslides, and coastal erosion, where solutions like Hexagonal Gabion are critical for resilience.

Key trends influencing the adoption of Hexagonal Gabion include the shift towards eco-friendly construction materials, the demand for flexible civil engineering structures capable of withstanding dynamic environmental forces, and advancements in material science leading to enhanced corrosion resistance and longevity. Engineers and urban planners are increasingly recognizing the long-term cost benefits and environmental advantages of gabion structures compared to traditional concrete or masonry solutions. The integration of geosynthetics and bioengineering techniques with gabion systems is also an emerging trend, enhancing their performance and ecological value. This holistic approach ensures that modern gabion applications not only provide structural integrity but also promote biodiversity and restore natural habitats.

Another significant driver is the increasing frequency and intensity of extreme weather events, which necessitate more robust and adaptive erosion control measures. Governments and private entities are investing heavily in protective infrastructure, creating a sustained demand for high-quality Hexagonal Gabion systems. The focus is shifting from merely preventing erosion to creating integrated land management solutions that work in harmony with natural processes. This strategic imperative underscores the importance of choosing manufacturers who adhere to stringent quality standards and offer comprehensive technical support.

Technical Specifications and Parameters of Hexagonal Gabions

The performance and suitability of a Hexagonal Gabion largely depend on its precise technical specifications. Understanding these parameters is crucial for engineers to design structures that meet specific project requirements and environmental conditions. The primary components of a gabion are the wire material, wire diameter, mesh size, and the type of protective coating applied. These elements collectively determine the gabion's tensile strength, resistance to deformation, durability, and service life.

Wire Material and Diameter: Typically, Hexagonal Gabion mesh is fabricated from high-tensile, low-carbon steel wire. The wire diameter is a critical parameter, influencing the gabion's overall strength and resilience. Common wire diameters range from 2.0 mm to 4.0 mm (approximately 14 to 8 gauge). Larger diameters offer increased structural integrity and resistance to abrasion, particularly in high-impact or aggressive environments. Edge wires, used to reinforce the perimeter of the gabion, are usually of a slightly larger diameter (e.g., 3.4 mm or 3.9 mm) to enhance stability and prevent unraveling.

Mesh Size and Type: The hexagonal mesh pattern, typically a double-twist or triple-twist weave, ensures that the wire will not unravel even if a single wire breaks. Common mesh sizes (distance between opposing hexagonal twists) include 60x80 mm, 80x100 mm, 80x120 mm, and 100x120 mm. The choice of mesh size depends on the size of the rock infill and the hydraulic conditions; smaller mesh sizes are used for smaller aggregate and in areas with higher flow velocities to prevent loss of fill material.

Protective Coatings and Corrosion Resistance: Given their outdoor application, Hexagonal Gabion wires require superior corrosion protection. The most common and effective coating is heavy-duty hot-dip galvanization, where steel wire is immersed in molten zinc to create a robust, sacrificial coating. Galvanization levels typically adhere to standards like ASTM A641/A975 or EN 10244-2, ensuring minimum zinc coating weights that can provide decades of protection in most environments. For highly corrosive environments, such as marine or polluted industrial areas, an additional PVC (Polyvinyl Chloride) coating is applied over the galvanized wire. This PVC coating, typically 0.5 mm thick, provides an extra layer of protection against chemical attack, abrasion, and UV radiation, significantly extending the service life of the gabion. The PVC material is chosen for its chemical inertness, flexibility, and resistance to environmental degradation.

Standard Dimensions: Hexagonal Gabion units are available in various standard sizes, commonly presented as length x width x height. Typical dimensions include 2m x 1m x 1m, 3m x 1m x 1m, 4m x 1m x 1m, and 2m x 1m x 0.5m. Custom dimensions are also available to meet specific project requirements, ensuring optimal fit and minimal material waste on site.

Below is a comprehensive table detailing the typical specifications for high-quality Hexagonal Gabion products, adhering to international industry standards.

Typical Hexagonal Gabion Technical Specifications

| Parameter | Description | Typical Range/Value | Relevant Standards |

|---|---|---|---|

| Wire Material | High-tensile, low-carbon steel wire | Zn-5Al-MM (Galfan/Galfan+), Heavily Galvanized | ASTM A856, EN 10244-2 |

| Mesh Wire Diameter | Diameter of wire forming the mesh | 2.0 mm - 3.0 mm (±0.05 mm) | ASTM A975, EN 10223-3 |

| Selvedge Wire Diameter | Diameter of wire reinforcing the edges | 3.0 mm - 4.0 mm (±0.05 mm) | ASTM A975, EN 10223-3 |

| Lacing Wire Diameter | Diameter of wire used for assembly | 2.2 mm (±0.05 mm) | ASTM A975, EN 10223-3 |

| Mesh Opening Size | Hexagonal opening dimensions | 60x80 mm, 80x100 mm, 100x120 mm, 120x150 mm | ASTM A975, EN 10223-3 |

| Zinc Coating Weight (Galvanized) | Minimum zinc mass per unit area | ≥ 240 g/m² (for 2.7mm wire) | ASTM A975, EN 10244-2 Class A |

| PVC Coating Thickness | Outer PVC layer thickness (if applicable) | ≥ 0.5 mm | ASTM A975, EN 10223-3 |

| Tensile Strength of Wire | Wire's resistance to breaking under tension | 350-550 N/mm² | EN 10218-1 |

| Puncture Resistance | Resistance to sharp object penetration | > 2.5 kN | (Based on mesh strength) |

| Corrosion Resistance (Salt Spray Test) | Resistance to corrosive environments | PVC Coated: > 3000 hours; Galvanized: > 500 hours | ASTM B117 |

These specifications are crucial for ensuring the structural integrity, longevity, and environmental suitability of Hexagonal Gabion installations across diverse geological and hydraulic conditions. Adherence to these standards guarantees a high-performance solution that can withstand the rigors of its intended application for decades.

Detailed Manufacturing Process of Hexagonal Gabion

The manufacturing of high-quality Hexagonal Gabion involves a meticulous process that ensures durability, structural integrity, and adherence to international standards. This intricate process transforms raw wire into resilient engineering components capable of enduring harsh environmental conditions for decades. Understanding the manufacturing steps provides insight into the quality and reliability of the final product.

1. Material Selection and Preparation

The foundation of a superior Hexagonal Gabion is the quality of its raw material. We utilize high-grade, low-carbon steel wire that meets stringent chemical composition and mechanical property requirements. This wire is selected for its optimal balance of strength, ductility, and formability, ensuring it can withstand the weaving process without fracturing and perform reliably under load. Before weaving, the wire undergoes a thorough cleaning process to remove any impurities, oils, or rust, which could compromise the adhesion of protective coatings.

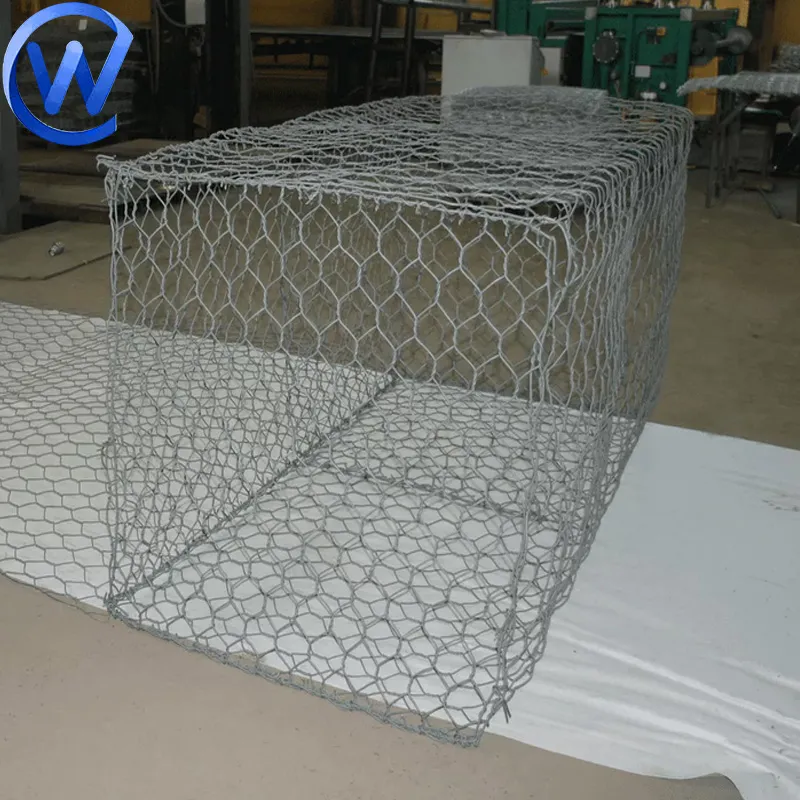

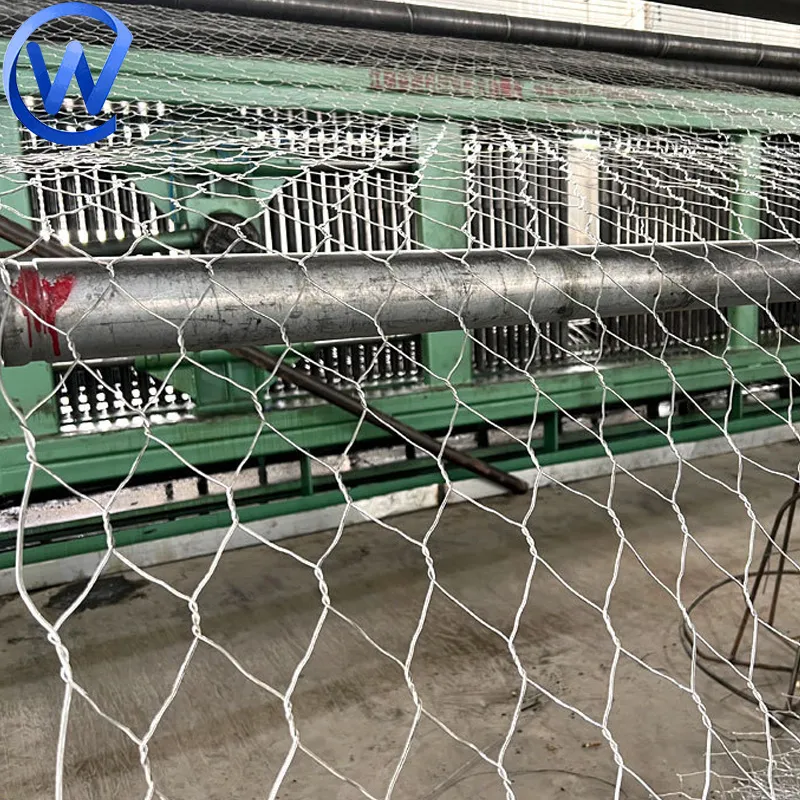

2. Wire Weaving - Double Twist Technology

The core of Hexagonal Gabion manufacturing is the weaving process. Advanced machinery is employed to precisely twist the steel wires into the characteristic hexagonal mesh pattern. The most common and robust method is the "double-twist" technique, where adjacent pairs of wires are twisted together for 1.5 turns, forming a strong, non-raveling mesh. This unique weaving method ensures that even if a wire is cut or breaks, the integrity of the surrounding mesh remains intact, preventing the structure from unraveling. This property is crucial for long-term stability and containment of the fill material, especially in dynamic environments. For applications requiring even greater resilience, triple-twist weaving can also be employed.

3. Surface Treatment and Corrosion Protection

Upon weaving, the mesh undergoes a critical surface treatment process to imbue it with exceptional corrosion resistance. The primary method is hot-dip galvanization, where the woven mesh is immersed in a bath of molten zinc. This process creates a metallurgically bonded, uniform zinc coating that acts as a sacrificial layer, protecting the steel wire from rust and corrosion. The thickness and uniformity of this zinc coating are rigorously controlled to meet or exceed international standards such as ASTM A641/A975 (Standard Specification for Metallic-Coated Carbon Steel Wire for Gabions and Revet Mattresses) and EN 10244-2 (Steel wire and wire products — Non-ferrous metallic coatings on steel wire — Part 2: Zinc or zinc alloy coatings). For applications in highly corrosive environments, such as coastal areas, polluted industrial sites, or acidic soils, an additional layer of PVC (Polyvinyl Chloride) coating is applied over the galvanized wire. This resilient polymer coating provides an extra barrier against chemical attack, abrasion, and UV degradation, extending the design life of the Hexagonal Gabion significantly. The PVC is typically extruded onto the wire after galvanization, ensuring a smooth, uniform, and tightly adhered layer.

4. Panel Cutting and Assembly Preparation

After the weaving and coating processes, the continuous mesh rolls are cut into precise panel dimensions according to standard gabion unit sizes (e.g., 2m x 1m x 1m). Specialized machinery ensures accurate cuts and prepares the individual panels (front, back, sides, lid, base, and diaphragms) for assembly. Diaphragms are internal baffles that divide longer gabion units into smaller cells, preventing the migration of fill material and maintaining the structural integrity of the unit. These panels are then edge-reinforced with heavier selvedge wires to provide additional strength and maintain the shape of the gabion during filling and consolidation.

5. Quality Control and Testing

Throughout the entire manufacturing process, rigorous quality control (QC) measures are implemented. This includes continuous monitoring of wire diameter, mesh size, tensile strength, zinc coating weight, and PVC coating thickness. Samples are regularly subjected to destructive and non-destructive tests in accredited laboratories to ensure compliance with relevant international standards, including ISO 9001 for quality management systems. Key tests include:

- Tensile Strength Test: To verify the wire's resistance to breaking.

- Elongation Test: To ensure the wire has sufficient ductility.

- Zinc Coating Weight Test: To confirm adequate galvanization for corrosion protection.

- Adhesion Test (for PVC coating): To ensure the PVC adheres firmly to the galvanized wire.

- Salt Spray Test (ASTM B117): To assess long-term corrosion resistance in harsh environments.

- Mesh Puncture Resistance: To measure the mesh's ability to resist concentrated loads.

These comprehensive tests guarantee that every Hexagonal Gabion unit leaving the facility meets the highest performance and durability standards, ensuring reliability in critical civil engineering applications. Our commitment to these stringent inspection standards minimizes the risk of product failure and maximizes the service life of the installed structures.

6. Packaging and Delivery

Once quality checks are complete, the gabion panels are flattened, folded, and bundled into compact packages for efficient transportation. This packaging minimizes shipping volume and protects the product during transit to the project site. Clear labeling ensures easy identification and handling upon arrival. The manufacturing process for Hexagonal Gabion is a testament to precision engineering, combining robust materials with advanced weaving techniques and comprehensive quality control to produce a reliable, long-lasting, and environmentally sound solution for a myriad of civil engineering challenges.

The typical service life of a heavily galvanized Hexagonal Gabion is often quoted at 25-50 years in non-aggressive environments. With the addition of a high-quality PVC coating, the service life can extend beyond 75 years, even in challenging conditions such as saline or acidic environments. This exceptional longevity provides significant long-term value and reduces the need for frequent maintenance or replacement, resulting in substantial life-cycle cost savings.

Applicable Industries and Advantages: Hexagonal Gabion structures find extensive applications across various industries, including:

- Civil Engineering: Retaining walls, bridge abutments, road embankments, slope stabilization.

- Water Conservancy: River training, channel lining, dam spillways, scour protection, flood control.

- Mining: Haul road protection, rockfall mitigation, erosion control on disturbed land.

- Landscaping & Architecture: Decorative walls, garden features, noise barriers.

- Coastal Protection: Seawalls, groynes, breakwaters.

In these scenarios, Hexagonal Gabion offers unique advantages:

- Permeability: Allows water to drain freely through the structure, alleviating hydrostatic pressure behind the wall and preventing structural failure. This is particularly beneficial in water-related projects, preventing the buildup of pressure that could destabilize rigid structures.

- Flexibility: Can withstand differential settlement and ground movement without fracturing, unlike rigid concrete structures. This adaptability is critical in unstable soil conditions or seismic zones.

- Environmental Integration: The voids within the rock-filled gabions can host vegetation over time, blending naturally into the landscape and enhancing biodiversity. This characteristic contributes to ecological restoration and green infrastructure initiatives.

- Cost-Effectiveness: Uses locally available rock fill, reducing material transport costs. Installation can often be performed with less specialized equipment and labor compared to concrete, leading to significant savings in project budgets. Furthermore, their inherent corrosion resistance and low maintenance requirements translate to long-term economic benefits.

- Corrosion Resistance: As detailed, the advanced galvanization and optional PVC coatings ensure exceptional resistance to environmental degradation, including resistance to chemical attacks from industrial runoff or saline environments. This extends the lifespan and reduces the need for costly repairs.

- Energy Absorption: When used in structures like revetments or breakwaters, the loose rock fill in Hexagonal Gabion units can absorb wave energy, dissipating it and protecting the underlying soil from scour.

Application Scenarios and Exemplary Case Studies

The versatility of Hexagonal Gabion structures allows for their deployment across an extensive range of civil engineering, environmental protection, and architectural projects. Their inherent flexibility, permeability, and durability make them an ideal choice for challenging ground conditions and dynamic environments. Here, we explore some prominent application scenarios and illustrate their efficacy with typical case studies.

1. River and Channel Bank Protection

Scenario: Rivers, canals, and waterways are constantly subjected to erosive forces from flowing water, leading to bank instability, sediment loss, and potential damage to adjacent infrastructure. Traditional rigid structures can be undermined by scour or can crack due to differential settlement.

Application of Hexagonal Gabion: Hexagonal Gabion are extensively used for river training works, channel lining, and bank stabilization. When stacked, they form flexible, permeable retaining walls that dissipate hydraulic energy, reducing scour and erosion. Their permeability allows groundwater to drain freely, preventing hydrostatic pressure buildup behind the structure. The flexibility of the mesh ensures that the structure can conform to minor ground movements without fracturing, maintaining its integrity even during floods or seismic events.

Case Study Example: In a major river restoration project along the Yangtze River in China, Hexagonal Gabion structures were deployed to stabilize over 5 kilometers of eroding riverbanks. The project faced challenges with fluctuating water levels and soft alluvial soils. By constructing multi-tiered gabion retaining walls and using gabion mattresses for scour protection at the toe, engineers successfully stabilized the banks, prevented further erosion, and created conditions for natural vegetation to re-establish, enhancing ecological value.

2. Retaining Walls and Slope Stabilization

Scenario: Road and railway embankments, bridge abutments, and cut slopes often require robust retaining structures to prevent landslides and soil erosion, especially in areas with unstable geology or steep gradients.

Application of Hexagonal Gabion: Hexagonal Gabion walls are a common choice for gravity retaining walls. Their mass and interlocking nature provide stability against earth pressures. The stacked gabion units, filled with dense rock, create a heavy, yet flexible, monolithic structure. Unlike concrete walls, gabion walls are inherently permeable, allowing water to drain, which mitigates hydrostatic pressure—a common cause of rigid wall failure. Their modular nature allows for construction even on uneven ground, adapting to the existing topography.

Case Study Example: A large infrastructure project in the mountainous regions of Northern India involved constructing new roads through challenging terrain prone to landslides. Traditional concrete retaining walls proved too costly and rigid for the geologically active area. Instead, engineers opted for a series of tiered Hexagonal Gabion retaining walls, ranging from 3 to 8 meters in height. The flexibility of the gabion structures allowed them to accommodate minor ground shifts without damage, and their permeability effectively managed water runoff, preventing saturation and reducing landslide risks. The project reported significant cost savings (approx. 30% compared to concrete) and improved environmental integration.

3. Erosion Control and Scour Protection

Scenario: Coastal areas, culvert outlets, and spillways are highly susceptible to scour, which is the erosion of material from the seabed, riverbed, or embankment. This can undermine foundations and lead to structural collapse.

Application of Hexagonal Gabion: Gabion mattresses (thin, wide gabion units) are particularly effective for surface erosion control and scour protection. They create a flexible, heavy apron that conforms to the underlying terrain, resisting the lifting forces of water flow. The rough surface of the rock fill dissipates wave and current energy, reducing the erosive power of water. Gabion baskets can also be used to form durable weir structures or energy dissipators at culvert outlets, preventing downstream scour.

Case Study Example: At a coastal protection project in the Philippines, severe storm surges were causing significant erosion of beachfront property. Engineers designed a permeable breakwater using large Hexagonal Gabion units filled with locally sourced rock. The gabion breakwater effectively absorbed the energy of incoming waves, reducing their impact on the shoreline. This solution proved more economical and environmentally friendly than solid concrete structures, allowing for better water circulation and promoting the recovery of local marine life.

4. Architectural and Landscape Applications

Scenario: Beyond traditional engineering, Hexagonal Gabion units are increasingly sought after for their aesthetic appeal and functional versatility in modern landscaping and architectural design, including residential, commercial, and public spaces.

Application of Hexagonal Gabion: Their natural, rustic appearance, combined with the ability to integrate vegetation, makes them popular for decorative garden walls, seating elements, noise barriers, and cladding for buildings. The choice of fill material can significantly alter the aesthetic, from crushed concrete to river rock or recycled glass, offering unique design possibilities. Their permeable nature is also advantageous for permeable paving systems and rainwater harvesting features.

Case Study Example: A contemporary urban park in Sydney, Australia, incorporated Hexagonal Gabion walls as key landscape features. These walls served multiple purposes: retaining earth for tiered gardens, providing informal seating areas, and acting as sound barriers near busy roads. The use of locally sourced sandstone offcuts as fill material ensured a harmonious blend with the natural environment, while also demonstrating a commitment to sustainable construction practices.

These case studies underscore the adaptability and efficacy of Hexagonal Gabion across diverse applications, proving their value as a reliable, economic, and environmentally conscious engineering solution for the most demanding projects. Their ability to deliver long-term structural integrity while integrating with natural processes makes them a preferred choice for forward-thinking engineers and developers worldwide.

Technical Advantages and Performance Metrics

The widespread adoption of Hexagonal Gabion in critical infrastructure projects is a testament to their superior technical advantages and robust performance characteristics. These benefits extend beyond mere structural stability, encompassing environmental compatibility, economic efficiency, and adaptability to complex engineering challenges. Analyzing these advantages provides a clear rationale for their selection over traditional rigid structures.

1. Inherent Flexibility and Adaptability to Ground Movement

One of the most significant advantages of Hexagonal Gabion structures is their inherent flexibility. Unlike rigid concrete or masonry walls, which can crack and fail under differential settlement or seismic activity, gabion structures can deform without losing their structural integrity. The double-twist wire mesh allows for minor adjustments in the structure's geometry as the underlying ground settles or shifts. This "monolithic yet flexible" characteristic is particularly vital in areas with unstable soils, expansive clays, or active fault lines. This adaptability significantly reduces the risk of catastrophic failure and minimizes long-term maintenance costs associated with structural repairs in dynamic geological environments.

2. Superior Permeability and Drainage Capabilities

Hexagonal Gabion structures are highly permeable, meaning they allow water to drain freely through the rock fill. This prevents the buildup of hydrostatic pressure behind retaining walls, a common cause of failure in impermeable structures. Effective drainage minimizes the risk of liquefaction in saturated soils and ensures the stability of the structure even during periods of heavy rainfall or fluctuating water levels. This natural drainage also negates the need for complex and costly subsurface drainage systems often required with concrete walls, further simplifying construction and reducing overall project expenditures.

3. Exceptional Durability and Extended Service Life

The longevity of a Hexagonal Gabion is primarily attributed to the robust quality of its wire and superior anti-corrosion coatings. Heavily galvanized steel wire, often supplemented with a durable PVC coating, provides remarkable resistance to rust, abrasion, and chemical degradation. In typical applications, a galvanized gabion can have a design life of 25 to 50 years, while a PVC-coated gabion can extend this to 75 years or more, even in harsh marine or polluted industrial environments. This extended service life minimizes the need for premature replacement, offering a superior return on investment over the life cycle of the project.

4. Environmental Compatibility and Bioengineering Potential

Hexagonal Gabion are inherently eco-friendly. The rock fill is typically sourced locally, reducing transportation costs and the carbon footprint associated with material procurement. The voids within the gabion structure provide an ideal environment for the growth of vegetation over time, allowing the structure to blend seamlessly with the natural landscape and even enhance biodiversity. This bioengineering potential supports natural habitat restoration, soil stabilization through root systems, and improved aesthetic integration, making them a cornerstone of sustainable infrastructure development.

5. Cost-Effectiveness and Simplified Installation

From a financial perspective, Hexagonal Gabion offer significant cost advantages. The primary fill material (rock) is often available locally, drastically reducing material acquisition and transportation costs. Installation is relatively straightforward and can be performed with basic construction equipment and local labor, minimizing reliance on specialized machinery or highly skilled crews typically required for concrete pouring. The modular nature of gabion units simplifies design and construction, leading to faster project completion times. Furthermore, their low maintenance requirements throughout their extended service life contribute to substantial long-term savings, making them an economically sound choice for both public and private sector projects.

6. High Structural Stability and Energy Dissipation

When properly filled and installed, Hexagonal Gabion units create a heavy, stable mass that can resist significant lateral earth pressures and hydraulic forces. Their mass-gravity nature makes them highly effective in applications such as retaining walls, bridge scour protection, and breakwaters. In hydraulic applications, the rough, porous surface of the gabion structure effectively dissipates wave and current energy, preventing scour and erosion of the underlying or adjacent soil. This energy-dissipating property is crucial for the long-term integrity of hydraulic structures.

In summary, the combined technical advantages of flexibility, permeability, durability, environmental compatibility, and cost-effectiveness make Hexagonal Gabion a compelling and often superior choice for a wide array of civil engineering, hydraulic, and environmental protection projects. These attributes ensure not only the immediate success of a project but also its sustained performance and positive environmental impact over the long term.

Manufacturer Comparison and Selection Guide

Selecting the right manufacturer for Hexagonal Gabion is a critical decision that directly impacts the success, longevity, and cost-effectiveness of your project. While many suppliers exist, not all offer the same level of quality, technical support, and commitment to client success. This section outlines key criteria for evaluating and comparing manufacturers, ensuring you partner with a provider that meets your exacting standards for B2B procurement.

Key Criteria for Manufacturer Evaluation:

1. Adherence to International Standards and Certifications

A reputable Hexagonal Gabion manufacturer must rigorously adhere to international quality and performance standards. Look for certifications such as ISO 9001 (Quality Management System) and compliance with specific product standards like ASTM A975 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses) and European Norms (e.g., EN 10223-3 for steel wire and wire products). These certifications are not merely badges; they indicate a commitment to consistent quality, traceable production processes, and proven product performance through independent testing. A manufacturer providing comprehensive test reports for wire tensile strength, zinc coating weight, and PVC coating adhesion demonstrates expertise and trustworthiness.

2. Material Quality and Coating Technology

Investigate the type and quality of steel wire used (e.g., high-tensile, low-carbon steel) and the specifics of their corrosion protection. Does the manufacturer offer both heavy-duty galvanization and PVC coating options? What are the minimum zinc coating weights and PVC thickness? Superior materials and advanced coating technologies directly translate to extended product lifespan and enhanced resistance to environmental degradation, particularly crucial for long-term infrastructure projects. Ask for details on the wire's elongation properties, as this impacts the gabion's flexibility.

3. Manufacturing Process and Technology

A manufacturer employing state-of-the-art weaving machines (double-twist or triple-twist) ensures the integrity of the mesh, preventing unraveling. Understanding their quality control checkpoints throughout the manufacturing process, from raw material inspection to finished product testing, provides confidence in their output. A highly automated process often leads to greater precision and consistency, reducing defects and ensuring uniform product quality across large orders.

4. Customization Capabilities and Technical Support

For complex projects, the ability to provide custom Hexagonal Gabion sizes, specialized coatings, or engineered solutions is invaluable. A manufacturer with a dedicated technical support team can assist with design considerations, material selection, installation guidance, and problem-solving. This level of partnership is essential for successful project execution, especially when dealing with unique geological or hydraulic conditions. Experienced technical staff can offer insights into the optimal design and configuration of gabion structures for specific site requirements.

5. Project Experience and Reputation

Review the manufacturer's portfolio of past projects. Do they have experience with projects similar in scale and complexity to yours? Are there client testimonials or case studies that demonstrate their capabilities and reliability? A strong track record and positive client feedback are indicative of a trustworthy partner. Longevity in the industry and a stable client base also speak volumes about a company's reliability and commitment to long-term relationships.

6. Logistics, Delivery, and After-Sales Support

Efficient logistics and reliable delivery are paramount for meeting project timelines. Inquire about their typical lead times, shipping options, and packaging methods to ensure products arrive on site in optimal condition. Comprehensive after-sales support, including warranty provisions and accessible technical assistance for post-installation queries, demonstrates a manufacturer's commitment beyond the point of sale. A clear warranty policy, typically covering manufacturing defects and coating performance, provides peace of mind.

Manufacturer Comparison Matrix (Illustrative Example):

| Feature/Criterion | Manufacturer A (Our focus) | Manufacturer B (Competitor) | Manufacturer C (Budget Option) |

|---|---|---|---|

| Certifications | ISO 9001, ASTM A975, EN 10223-3 | ISO 9001 | Basic QA, some local certs |

| Wire Coating Options | Heavy Galvanized, Zn-5Al, PVC Coated | Galvanized, some PVC | Mainly Galvanized (lighter coating) |

| PVC Coating Quality | ≥0.5mm, UV & Chemical resistant | 0.4-0.5mm, variable quality | <0.4mm, limited resistance |

| Technical Support | Comprehensive (design, installation, post-sale) | Standard (product info) | Minimal |

| Customization | Extensive (size, material, specific needs) | Limited standard variations | None |

| Typical Lead Time | 2-4 weeks (project-dependent) | 3-6 weeks | Longer, inconsistent |

| Warranty/Guarantee | Strong, clear warranty (25-75 yrs+) | Basic, limited | Variable, often absent |

| Pricing Strategy | Value-focused, competitive for quality | Mid-range | Lowest cost, compromises quality |

By meticulously evaluating these factors, B2B clients can make informed decisions, ensuring they partner with a Hexagonal Gabion manufacturer that not only provides a high-quality product but also offers the comprehensive support and expertise essential for the successful execution of critical engineering projects. Prioritizing quality, compliance, and partnership over mere cost savings will invariably lead to better long-term project outcomes and reduced lifecycle costs.

Customization and Tailored Solutions for Hexagonal Gabion Projects

In complex engineering and environmental protection projects, off-the-shelf solutions often fall short of meeting unique site-specific challenges. Recognizing this, leading Hexagonal Gabion manufacturers offer extensive customization capabilities, ensuring that every project, regardless of its scale or intricacy, benefits from perfectly tailored gabion solutions. This bespoke approach is crucial for optimizing structural performance, enhancing aesthetics, and achieving cost efficiencies.

1. Tailored Dimensions and Configurations

While standard Hexagonal Gabion sizes (e.g., 2x1x1m) are widely available, many projects require non-standard dimensions to fit specific site contours, integrate with existing structures, or optimize fill volume. Customization allows for the precise fabrication of gabions in varying lengths, widths, and heights, minimizing waste and ensuring optimal structural fit. This includes not only custom basket sizes but also specialized forms like gabion mattresses for shallow erosion control or cylindrical gabions for specific hydraulic applications. The ability to specify precise dimensions can significantly reduce on-site cutting and adjustment, streamlining installation and saving labor costs.

2. Specialized Coatings for Extreme Environments

Beyond standard heavy galvanization and PVC coatings, customization extends to specialized protective layers for exceptionally aggressive environments. This might include high-performance polymer coatings designed to resist specific chemical pollutants, extreme UV radiation, or highly abrasive flows. Manufacturers can also offer zinc-aluminum (Zn-5Al or Galfan) coatings, which provide enhanced corrosion resistance compared to traditional galvanization, particularly beneficial in coastal or industrial settings. These tailored coatings ensure the long-term integrity of the Hexagonal Gabion even in the most challenging conditions, extending their lifespan far beyond standard expectations.

3. Wire Diameter and Mesh Size Optimization

Depending on the anticipated loads, hydraulic forces, and the type of fill material, specific wire diameters and mesh opening sizes can be optimized. For high-impact areas or structures subjected to significant external forces, a heavier gauge wire can be specified to enhance puncture resistance and overall structural robustness. Conversely, finer mesh sizes may be required to retain smaller aggregate fill materials or to provide a more visually refined finish. This precise tailoring ensures that the gabion performs optimally for its intended function without over-engineering.

4. Engineering Consultation and Design Support

A hallmark of a truly custom solution provider is comprehensive engineering consultation. This involves collaborating with project engineers and designers from the initial concept phase. Expert technical teams can offer insights into optimal gabion wall configurations, foundation requirements, stability analysis, and integration with other geotechnical elements. This collaborative approach ensures that the customized Hexagonal Gabion solution is not just a product, but a fully engineered system designed to address all project-specific challenges, including seismic design, slope stability, and hydraulic performance.

Benefits of Custom Solutions:

- Optimized Performance: Tailored designs lead to structures that perfectly meet the functional requirements and specific site conditions, maximizing efficacy and longevity.

- Cost Efficiency: By minimizing material waste and streamlining installation, customized gabions can reduce overall project costs. Avoiding unnecessary over-engineering also contributes to savings.

- Enhanced Aesthetics: Custom dimensions and fill material considerations allow for greater architectural flexibility and seamless integration with the surrounding landscape.

- Risk Mitigation: Precisely engineered solutions address specific project risks, from unique soil conditions to extreme environmental exposures, enhancing safety and structural reliability.

- Accelerated Project Timelines: Pre-fabricated custom units simplify on-site assembly, reducing construction time and labor intensity.

Engaging with a manufacturer that possesses robust customization capabilities transforms the procurement of Hexagonal Gabion from a simple commodity purchase into a strategic partnership, delivering superior value and ensuring the successful execution of even the most demanding engineering and environmental projects.

Quality Assurance and Compliance: Our Commitment to Excellence

In the critical domain of civil engineering and environmental infrastructure, the quality and compliance of materials are paramount. For Hexagonal Gabion, this translates to an unwavering commitment to rigorous quality assurance (QA) protocols and strict adherence to international standards. Our manufacturing process integrates multi-stage quality control to guarantee that every gabion unit we produce delivers uncompromising performance, durability, and reliability.

1. Multi-Stage Internal Quality Control

Our QA process begins with the meticulous selection of raw materials. All incoming steel wire undergoes stringent inspection for chemical composition, tensile strength, elongation, and surface cleanliness, ensuring it meets our exacting specifications before entering production. During the weaving process, automated systems continuously monitor mesh formation, wire alignment, and twist integrity. Post-weaving, samples are regularly taken to verify mesh opening dimensions, wire diameters, and overall structural consistency. The galvanization and PVC coating stages are subject to rigorous checks, including measuring coating thickness, adhesion, and uniformity. Any deviation from specified parameters triggers an immediate corrective action, ensuring only defect-free products proceed to the next stage. This comprehensive in-process quality control minimizes the risk of non-conformance.

2. Adherence to International Standards and Certifications

We pride ourselves on full compliance with globally recognized quality and product performance standards. Our manufacturing facilities are ISO 9001 certified, demonstrating a robust quality management system that ensures consistent product quality and customer satisfaction. Our Hexagonal Gabion products conform strictly to:

- ASTM A975-97 (2018): Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Carbon Steel Wire).

- EN 10223-3:2013: Steel wire and wire products - Part 3: Steel wire for gabions and gabion units.

- EN 10244-2:2009: Steel wire and wire products - Non-ferrous metallic coatings on steel wire - Part 2: Zinc or zinc alloy coatings (for galvanization).

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus (for corrosion resistance testing).

These certifications and compliance with international standards provide our clients with the assurance that our Hexagonal Gabion products meet the highest benchmarks for safety, performance, and durability, thereby reducing project risks and ensuring long-term structural integrity.

3. Independent Testing and Verification

Beyond our internal QC, we regularly send samples of our Hexagonal Gabion wire and mesh to independent, accredited third-party laboratories for testing. This external verification provides an unbiased assessment of our product's performance characteristics, including:

- Wire Tensile Strength and Elongation: To confirm mechanical properties crucial for structural resilience.

- Coating Mass and Uniformity: To verify the thickness and consistency of galvanized and PVC coatings, directly impacting corrosion resistance.

- Mesh Puncture and Unraveling Resistance: To test the integrity of the hexagonal weave under stress.

- Accelerated Weathering and Salt Spray Testing: To simulate long-term environmental exposure and assess corrosion resistance in aggressive conditions.

The results of these tests are made available to our clients, offering complete transparency and reinforcing the technical merits of our products. This commitment to third-party verification underscores our dedication to providing robust, reliable, and scientifically proven Hexagonal Gabion solutions.

4. Comprehensive Warranty and After-Sales Support

Our confidence in the quality and longevity of our Hexagonal Gabion products is reflected in our comprehensive warranty policy. We provide clear, extended warranties that cover manufacturing defects and the performance of our protective coatings under specified environmental conditions. Beyond the warranty, our dedicated customer support team and technical experts are available to assist with any queries related to product application, installation best practices, or troubleshooting, ensuring our clients receive full support throughout the lifecycle of their projects. This holistic approach to quality assurance and customer support provides our B2B partners with peace of mind and reinforces our position as a trustworthy and reliable supplier in the global market.

Client Success Stories and Experiential Insights

Our commitment to delivering high-quality Hexagonal Gabion solutions is best reflected in the successful outcomes of our clients' projects. Through strategic partnerships and the provision of meticulously engineered products, we have consistently helped overcome complex geotechnical and environmental challenges across various sectors. These success stories highlight the practical benefits and long-term value that our gabion solutions bring to B2B clients.

1. Large-Scale Dam Spillway Erosion Control

Challenge: A major hydroelectric dam in a Southeast Asian country faced severe erosion issues around its spillway and downstream channels due to high-velocity water discharge during monsoon seasons. Traditional concrete solutions were deemed too costly, time-consuming, and prone to cracking under extreme hydraulic pressure and seismic activity prevalent in the region.

Solution with Hexagonal Gabion: Our team collaborated with the dam engineers to design a comprehensive erosion control system utilizing heavy-duty, PVC-coated Hexagonal Gabion mattresses and baskets. Over 10,000 cubic meters of gabion units were supplied for the project. The gabion mattresses (0.3m thick) were laid out in a cascading design to dissipate energy along the spillway, while 1m x 1m x 2m gabion baskets formed retaining walls along the channel banks. The PVC coating was essential for long-term resistance to constant water exposure and local environmental conditions.

Outcome: The project was completed within budget and ahead of schedule. Post-installation, the gabion structures effectively withstood multiple monsoon seasons, demonstrating superior energy dissipation and scour protection. The flexibility of the gabions allowed them to adapt to minor ground movements without structural damage. The client reported a 40% cost saving compared to initial concrete design estimates and praised the minimal environmental impact, with local vegetation beginning to establish within the gabion voids within two years.

2. Urban Landslide Remediation and Slope Stabilization

Challenge: A rapidly developing urban area on a steep hillside in Latin America experienced recurrent landslides, threatening residential properties and critical infrastructure. The unstable clayey soils and heavy rainfall required an immediate, robust, yet adaptable slope stabilization solution that could be rapidly deployed.

Solution with Hexagonal Gabion: We provided a tailored solution involving tiered Hexagonal Gabion retaining walls, designed with varying heights and base widths to account for differential earth pressures. Heavily galvanized gabions with a wire diameter of 3.0mm were chosen for maximum strength and corrosion resistance. Our technical team provided on-site training to local contractors for efficient assembly and filling, emphasizing proper compaction techniques for optimal stability.

Outcome: The gabion walls provided immediate and lasting stability to the hillside. Their permeability effectively managed groundwater seepage, which was a primary contributor to the landslides. Local community feedback highlighted the aesthetic improvement and increased sense of security. The project was lauded by municipal authorities for its effectiveness, speed of implementation, and cost-efficiency, reducing the risk of future property damage and ensuring public safety.

3. Coastal Erosion Mitigation for Resorts

Challenge: A luxury beachfront resort in the Caribbean was facing significant beach erosion due to rising sea levels and intense tropical storms, threatening its infrastructure and natural amenities. A solution was needed that would protect the coastline while maintaining the area's natural beauty and allowing for beach replenishment.

Solution with Hexagonal Gabion: Our engineers proposed a system of permeable offshore breakwaters constructed from large Hexagonal Gabion units, filled with local coral rock. PVC-coated gabions were specified to withstand the highly corrosive saline environment. The design incorporated specific angles and orientations to promote sediment accretion behind the structures, gradually restoring the beach. Gabion mattress revetments were also installed along the immediate shoreline for localized protection.

Outcome: Within two years, significant beach accretion was observed, restoring the resort's beachfront. The gabion breakwaters effectively attenuated wave energy, protecting the shoreline from storm damage. The natural look of the rock-filled gabions blended well with the resort's aesthetic, and their porous nature supported the return of marine life. This sustainable approach secured the resort's long-term viability and enhanced its environmental stewardship reputation.

These examples underscore our proven track record in delivering high-performance, cost-effective, and environmentally sensitive Hexagonal Gabion solutions for diverse and demanding engineering challenges. Our expertise extends beyond manufacturing, encompassing comprehensive technical support and partnership to ensure client success from concept to completion.

Frequently Asked Questions (FAQ) about Hexagonal Gabion

This FAQ section addresses common queries from B2B clients and technical professionals regarding the specification, installation, performance, and maintenance of Hexagonal Gabion structures, offering clear, concise, and authoritative answers.

Q1: What is the primary difference between Hexagonal Gabion and welded mesh gabions?

A1: The fundamental difference lies in their manufacturing process and structural behavior. Hexagonal Gabion (or double-twist woven mesh gabions) are made from a continuous mesh that is twisted together to form hexagonal openings. This weaving process provides inherent flexibility, allowing the structure to deform and settle without fracturing, which is ideal for unstable ground or seismic zones. Welded mesh gabions, conversely, are constructed from welded wire panels. While they offer a more rigid, aesthetically uniform appearance and are quicker to erect, they are less flexible and more susceptible to cracking or failure under differential settlement or dynamic loading. For critical civil engineering applications where ground movement is a concern, the flexibility of Hexagonal Gabion is generally preferred.

Q2: How long can I expect a Hexagonal Gabion structure to last?

A2: The service life of a Hexagonal Gabion largely depends on the type of wire coating and the environmental conditions. Heavily galvanized gabions typically have a design life of 25 to 50 years in non-aggressive environments (e.g., inland, stable soil conditions). When an additional PVC coating is applied over the galvanized wire, the lifespan can extend significantly, often exceeding 75 years, even in highly corrosive environments like coastal areas, polluted industrial sites, or acidic soils. The durability also relies on proper installation, adequate rock fill, and minimal abrasion.

Q3: What type of fill material should be used for Hexagonal Gabion, and does it affect performance?

A3: The ideal fill material for Hexagonal Gabion is hard, durable, non-frost susceptible, and impermeable rock or stone. The size of the rock should be larger than the mesh opening to prevent loss of material. Typically, stones ranging from 100 mm to 250 mm (4 to 10 inches) are suitable for 80x100 mm mesh. The quality and type of fill material significantly impact the gabion's mass, permeability, and structural stability. Angular, interlocking rocks generally provide better stability than rounded river stones. Using poor-quality, degradable, or undersized fill material can compromise the structure's integrity and lead to premature failure. Local sourcing of fill material is encouraged to reduce costs and environmental impact, provided it meets specified quality criteria.

Q4: Are Hexagonal Gabion structures environmentally friendly?

A4: Yes, Hexagonal Gabion are considered highly environmentally friendly. Their key eco-benefits include: 1) Permeability: They allow water to drain, maintaining natural groundwater flow and preventing hydrostatic pressure. 2) Local Material Use: They typically use locally sourced rock fill, reducing transportation emissions and costs. 3) Bioengineering Potential: The voids within the rock fill can be vegetated over time, encouraging plant growth and natural habitat restoration, blending the structure seamlessly with the landscape. 4) Low Carbon Footprint: Compared to concrete, their production and installation generally have a lower carbon footprint. This makes them a preferred choice for sustainable infrastructure and green engineering projects.

Q5: What are the typical delivery timelines for large orders of Hexagonal Gabion?

A5: Delivery timelines for large orders of Hexagonal Gabion can vary depending on the order volume, specific customization requirements, and current production schedule. For standard sizes and coatings, typical lead times range from 2 to 4 weeks for production, followed by transit time. For highly customized orders or exceptionally large quantities (e.g., thousands of cubic meters), lead times may extend to 6-8 weeks. We recommend early engagement with our sales and technical teams to discuss project timelines and logistical needs. We also ensure efficient packaging to optimize shipping costs and protect the product during transit.

Q6: How does your company ensure the quality and compliance of Hexagonal Gabion products?

A6: Our commitment to quality is multifaceted. We maintain ISO 9001 certification for our quality management system. Our products are manufactured to stringent international standards, including ASTM A975 and EN 10223-3. We implement rigorous multi-stage internal quality control, from raw material inspection (wire diameter, tensile strength) to in-process checks (mesh integrity, coating uniformity) and final product testing. Additionally, we regularly engage independent third-party laboratories for unbiased verification of critical parameters like zinc coating weight, PVC coating thickness, and salt spray resistance. This comprehensive QA approach ensures every Hexagonal Gabion unit meets the highest performance and durability standards.

Delivery and Logistics for Hexagonal Gabion

Efficient and reliable delivery is as crucial as product quality in ensuring the seamless execution of your engineering projects. Our streamlined logistics process for Hexagonal Gabion is designed to provide timely and secure delivery to project sites worldwide, minimizing delays and optimizing supply chain efficiency for our B2B partners.

1. Packaging and Protection

Each Hexagonal Gabion unit is meticulously prepared for shipment. The gabion panels are flattened, folded, and bundled into compact, secure packages. This optimized packaging minimizes volumetric space, thereby reducing shipping costs significantly. For added protection during transit, especially for longer journeys or adverse conditions, bundles are often wrapped in durable, weather-resistant materials or placed on pallets, preventing damage from moisture, dust, or handling. All bundles are clearly labeled with product specifications and order details for easy identification and inventory management upon arrival at the project site.

2. Transportation Modes and Global Reach

We leverage a comprehensive network of logistics partners to facilitate reliable transportation of Hexagonal Gabion products, whether by sea, road, or rail. For international shipments, container111ized ocean freight is typically employed for cost-effectiveness and capacity, with precise scheduling to align with project timelines. For domestic or regional deliveries, dedicated truck fleets ensure timely arrival at job sites, even in remote locations. Our logistics team possesses extensive experience in managing customs clearance and international shipping regulations, ensuring a smooth and compliant delivery process for global projects.

3. Typical Lead Times and Order Processing

Our standard lead time for the production of Hexagonal Gabion ranges from 2 to 4 weeks, depending on the volume and customization requirements. This timeframe allows for material sourcing, manufacturing, quality control, and initial packaging. Following production, transit times vary based on destination and chosen shipping method. We encourage our clients to place orders with sufficient lead time, especially for large-scale or time-sensitive projects. Upon order confirmation, clients receive regular updates on their order status, including production milestones and shipping information, ensuring complete transparency throughout the delivery process.

4. Site Delivery Coordination and Support

Our logistics team works closely with clients to coordinate delivery schedules that align with project site readiness and installation timelines. We understand that efficient site logistics are critical for minimizing downtime and maximizing productivity. For complex deliveries, we can provide guidance on offloading requirements and safe handling procedures for the Hexagonal Gabion units, ensuring that products are received and managed effectively on site. This proactive coordination minimizes potential logistical bottlenecks and contributes to the overall smooth progression of your construction project.

Our robust delivery and logistics framework underscores our commitment to not only providing superior Hexagonal Gabion products but also ensuring they arrive efficiently and intact, ready for immediate deployment on your critical engineering ventures.

Customer Support and Partnership: Our Holistic Approach

At the core of our operations is a deep-seated commitment to fostering long-term partnerships with our B2B clients. We believe that providing exceptional Hexagonal Gabion products is only part of the equation; comprehensive customer support, technical assistance, and a collaborative approach are equally vital to ensuring project success and client satisfaction. Our partnership model extends far beyond the point of sale, encompassing every stage of your project's lifecycle.

1. Dedicated Technical Consultation and Design Assistance

Our team of experienced engineers and technical specialists is available to provide in-depth consultation from the initial design phase. We assist clients in selecting the most appropriate Hexagonal Gabion specifications (wire type, coating, mesh size, dimensions) based on specific project requirements, geological conditions, and hydraulic forces. We offer expert guidance on structural design, stability analysis, and integration with other geotechnical elements. This collaborative design assistance ensures that the chosen gabion solution is optimized for performance, cost-effectiveness, and compliance with all relevant engineering standards.

2. On-Site Installation Guidance and Training

Proper installation is paramount to the long-term integrity of any Hexagonal Gabion structure. We offer comprehensive installation guidelines and, for larger or more complex projects, can arrange for on-site technical support and training for your construction teams. This includes best practices for gabion assembly, wire lacing, proper rock filling and compaction, and connecting units to form a stable, monolithic structure. This direct support helps ensure efficient and correct installation, maximizing the gabion's performance and service life, while also minimizing potential construction delays or errors.

3. Responsive After-Sales Support and Troubleshooting

Our commitment to our clients does not end with delivery. Our dedicated customer service team provides responsive after-sales support for any queries or concerns that may arise post-installation. Whether it's clarification on maintenance procedures, advice on minor repairs, or assistance with unexpected site conditions, our experts are readily available to offer timely and practical solutions. This ongoing support underscores our dedication to the sustained success of your projects and the durability of our Hexagonal Gabion products.

4. Long-Term Relationship Building and Feedback Integration

We view each project as an opportunity to build a lasting relationship. We actively seek feedback from our clients to continuously improve our products, services, and support mechanisms. This iterative process, driven by real-world project insights, ensures that our Hexagonal Gabion solutions evolve to meet the ever-changing demands of the engineering and construction industries. By fostering open communication and mutual trust, we aim to be your preferred partner for all your gabion and geotechnical material needs, providing consistent quality and unparalleled support for years to come.

Through this holistic approach to customer support and partnership, we not only supply premium Hexagonal Gabion products but also provide the expertise and collaboration necessary to navigate complex project challenges, ensuring successful outcomes and enduring value for our B2B clients.

Conclusion: The Enduring Value of Hexagonal Gabion in Modern Engineering

The Hexagonal Gabion stands as a testament to adaptive and sustainable engineering, offering a robust, flexible, and environmentally harmonious solution for a multitude of geotechnical, hydraulic, and architectural challenges. Its intrinsic advantages—ranging from unparalleled flexibility in accommodating ground movement and superior permeability for effective drainage, to exceptional durability through advanced corrosion protection and significant cost-effectiveness—make it an indispensable component in modern infrastructure development and environmental protection initiatives.

As global trends lean towards more resilient infrastructure, climate change adaptation, and sustainable construction practices, the demand for high-quality Hexagonal Gabion solutions is set to continue its upward trajectory. The ability of these structures to integrate with natural landscapes, promote vegetation growth, and withstand dynamic environmental forces positions them as a foundational element for a future-proof built environment. From mitigating severe erosion along vital waterways and stabilizing critical transportation corridors to creating aesthetically pleasing and functional urban landscapes, the versatility of the Hexagonal Gabion is continuously being redefined.

Our commitment extends beyond merely manufacturing and supplying Hexagonal Gabion. We partner with B2B clients, offering extensive technical expertise, bespoke customization capabilities, rigorous quality assurance, and comprehensive after-sales support. This holistic approach ensures that every project benefits from a solution that is not only technically superior but also perfectly aligned with specific project requirements and long-term objectives. By choosing high-standard Hexagonal Gabion, clients invest in proven reliability, environmental stewardship, and enduring value, safeguarding their infrastructure investments for decades to come.

References

- ASTM International. (2018). A975/A975M-18: Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Carbon Steel Wire). West Conshohocken, PA: ASTM International.

- EN 10223-3:2013. (2013). Steel wire and wire products - Part 3: Steel wire for gabions and gabion units. European Committee for Standardization.

- International Organization for Standardization. (2015). ISO 9001:2015: Quality management systems — Requirements. ISO.

- Terzaghi, K., Peck, R. B., & Mesri, G. (1996). Soil Mechanics in Engineering Practice. John Wiley & Sons.

- U.S. Department of Transportation, Federal Highway Administration. (2001). FHWA-SA-96-071: Design and Construction of Driven Pile Foundations. (Provides context on erosion control and foundation stability in infrastructure).

-

Durable Fence Barbed Wire Solutions for Global Security & Agriculture

NewsNov.24,2025

-

Comprehensive Guide to Barbed Fence Wire – Durability, Uses & Innovations

NewsNov.23,2025

-

Barb Wire Price Per Roll – Understanding Costs, Trends & Global Applications

NewsNov.22,2025

-

Stainless Steel Barbed Wire: Durable Security for Global Industries & Relief Efforts

NewsNov.22,2025

-

Comprehensive Guide to Razor Wire Prices: Factors, Trends & Vendors

NewsNov.21,2025

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025