-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 16, 2025 13:15 Back to list

Perforated Metal Mesh - Durable, Custom Sizes & Wholesale

[perforated metal mesh,perforated metal mesh sheet,custom perforated metal mesh sheet,custom perforated metal mesh,wholesale perforated metal mesh,perforated metal mesh exporters,perforated metal mesh manufacturers,metal stainless steel perforated metal mesh,wholesale perforated metal mesh sheet,perforated metal mesh supplier,perforated metal mesh factory] is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal mesh and mesh products. This article explores how HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- [perforated metal mesh,perforated metal mesh sheet,custom perforated metal mesh sheet,custom perforated metal mesh,wholesale perforated metal mesh,perforated metal mesh exporters,perforated metal mesh manufacturers,metal stainless steel perforated metal mesh,wholesale perforated metal mesh sheet,perforated metal mesh supplier,perforated metal mesh factory] Overview

- Benefits & Use Cases of [perforated metal mesh,perforated metal mesh sheet,custom perforated metal mesh sheet,custom perforated metal mesh,wholesale perforated metal mesh,perforated metal mesh exporters,perforated metal mesh manufacturers,metal stainless steel perforated metal mesh,wholesale perforated metal mesh sheet,perforated metal mesh supplier,perforated metal mesh factory] in Manufacturing of metal mesh and mesh products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on [perforated metal mesh,perforated metal mesh sheet,custom perforated metal mesh sheet,custom perforated metal mesh,wholesale perforated metal mesh,perforated metal mesh exporters,perforated metal mesh manufacturers,metal stainless steel perforated metal mesh,wholesale perforated metal mesh sheet,perforated metal mesh supplier,perforated metal mesh factory] from HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.

[perforated metal mesh,perforated metal mesh sheet,custom perforated metal mesh sheet,custom perforated metal mesh,wholesale perforated metal mesh,perforated metal mesh exporters,perforated metal mesh manufacturers,metal stainless steel perforated metal mesh,wholesale perforated metal mesh sheet,perforated metal mesh supplier,perforated metal mesh factory] Overview

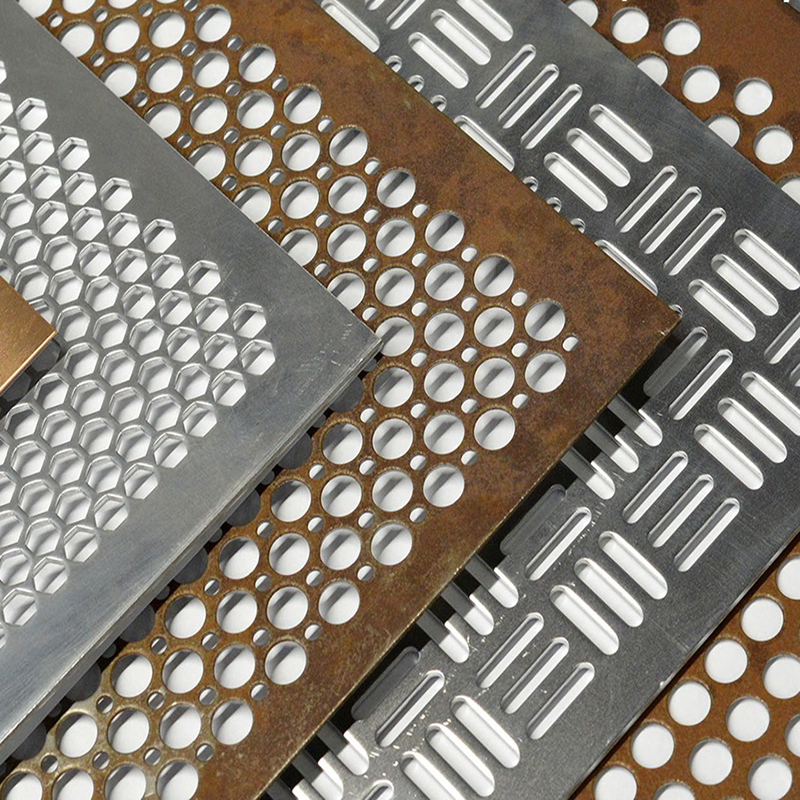

Perforated metal mesh is a precision-punched sheet featuring controlled hole patterns that deliver strength, ventilation, filtration, light diffusion, and acoustic performance. In fabricated metal products, a perforated metal mesh sheet serves as a structural and functional element across enclosures, guards, panels, and screens. HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. manufactures and exports standard and custom perforated metal mesh sheets using carbon steel, aluminum, galvanized steel, and metal stainless steel perforated metal mesh (304/316) for demanding environments.

Typical specifications include thickness from 0.3–10.0 mm, hole diameters from 0.5–50 mm, open area 5–60%, and patterns such as round, slotted, square, hexagonal, and decorative designs. Standard sheets (1000 × 2000 mm, 1220 × 2440 mm) and coil-fed options are available, along with finishing like powder coating, anodizing, galvanizing, and passivation. Tight tolerances, leveling, and deburring ensure flat, burr-free surfaces prepared for downstream fabrication (bending, welding, and powder coating). As a reliable perforated metal mesh manufacturer and perforated metal mesh exporter, HEBEI WEICHUN provides OEM/ODM support and rapid sampling for custom perforated metal mesh.

Benefits & Use Cases of [perforated metal mesh,perforated metal mesh sheet,custom perforated metal mesh sheet,custom perforated metal mesh,wholesale perforated metal mesh,perforated metal mesh exporters,perforated metal mesh manufacturers,metal stainless steel perforated metal mesh,wholesale perforated metal mesh sheet,perforated metal mesh supplier,perforated metal mesh factory] in Manufacturing of metal mesh and mesh products

Across manufacturing of metal mesh and mesh products, perforated mesh is chosen for its optimal strength-to-weight ratio and predictable airflow. Applications include machine guarding and safety enclosures, HVAC and ventilation grilles, filtration and sieving, acoustic wall/ceiling panels, architectural façades and sunscreens, stair treads, anti-slip plates, agricultural screening, and automotive heat shields. A custom perforated metal mesh sheet can tune open area, hole geometry, and thickness to achieve target pressure drop, sound absorption, and structural load requirements.

HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. delivers competitive advantages: consistent hole quality from advanced punching and leveling lines, coil-to-sheet efficiency for long runs, edge margins optimized for minimal scrap, and surface treatments that resist corrosion. For corrosive or hygienic settings, metal stainless steel perforated metal mesh offers long service life and cleanability. As a wholesale perforated metal mesh sheet partner and experienced perforated metal mesh supplier, the company aligns tooling, lead times, and packaging with B2B schedules—supporting both high-volume programs and specialized custom perforated metal mesh projects.

Cost, Maintenance & User Experience

Total cost of ownership depends on material grade, thickness, hole density, pattern complexity, finishing, and order volume. By leveraging bulk sourcing and coil-fed production, HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.—a dependable perforated metal mesh factory—helps reduce unit costs for wholesale perforated metal mesh. Smart nesting, precise margins, and flatness control minimize rework in downstream bending and welding, improving throughput and lowering labor costs.

In use, perforated metal mesh is low maintenance: it withstands frequent cleaning, resists abrasion, and retains dimensional stability. Stainless and galvanized finishes extend life in outdoor and process environments, improving ROI compared with non-metal alternatives. Fabricated metal products customers report easier assembly due to consistent thickness and burr-free edges, as well as reduced scrap during panel alignment. Clear labeling, export-ready packaging, and reliable schedules from seasoned perforated metal mesh exporters enhance the overall user experience, especially for multi-site OEMs and global contractors.

Sustainability & Market Trends in manufacturing

Manufacturers are adopting recyclable metals, energy-efficient processes, and designs that reduce material intensity. Perforated metal inherently supports sustainability by using durable, fully recyclable substrates and enabling energy savings—for example, façades and sunscreens that improve daylighting and reduce HVAC loads. HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. prioritizes responsible sourcing and efficient punching practices that limit scrap, with offcuts recycled back into the metal supply chain.

Market trends show rising demand for custom perforated metal mesh that balances aesthetics, airflow, and acoustic control. Compliance requests around RoHS/REACH and material traceability are becoming standard in B2B procurement. As a forward-thinking perforated metal mesh manufacturer and supplier, HEBEI WEICHUN supports documentation needs (e.g., material test reports) and collaborates with specifiers to meet project-specific performance and environmental targets, positioning its wholesale perforated metal mesh as future-ready for global markets.

Conclusion on [perforated metal mesh,perforated metal mesh sheet,custom perforated metal mesh sheet,custom perforated metal mesh,wholesale perforated metal mesh,perforated metal mesh exporters,perforated metal mesh manufacturers,metal stainless steel perforated metal mesh,wholesale perforated metal mesh sheet,perforated metal mesh supplier,perforated metal mesh factory] from HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.

From filtration to façades, perforated metal mesh empowers engineered performance with durability, airflow control, and visual appeal. Whether you need a standard perforated metal mesh sheet or a fully custom perforated metal mesh solution, HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. combines manufacturing expertise, dependable exports, and responsive service to support B2B outcomes. Choose a trusted perforated metal mesh supplier and factory focused on quality, value, and on-time delivery.

Contact us: email: sales@galvanizedmetalmesh.com

Visit our website: https://www.galvanizedmeshproducts.com

-

Durable Fence Barbed Wire Solutions for Global Security & Agriculture

NewsNov.24,2025

-

Comprehensive Guide to Barbed Fence Wire – Durability, Uses & Innovations

NewsNov.23,2025

-

Barb Wire Price Per Roll – Understanding Costs, Trends & Global Applications

NewsNov.22,2025

-

Stainless Steel Barbed Wire: Durable Security for Global Industries & Relief Efforts

NewsNov.22,2025

-

Comprehensive Guide to Razor Wire Prices: Factors, Trends & Vendors

NewsNov.21,2025

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025