-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 18, 2024 12:52 Back to list

Innovative Manufacturing Techniques in Razor Wire Production and Their Applications

Razor wire, often associated with security and perimeter protection, is an essential product used in various applications, including military installations, prisons, and commercial properties. Razor wire factories play a crucial role in manufacturing this effective deterrent, producing a product characterized by its sharp blades and robust wire coils designed to prevent unauthorized access.

The production process in a razor wire factory involves several steps. Initially, high-quality steel is sourced, as durability and resilience are paramount for security applications. The steel is then processed into thin strips, which undergo various treatments to enhance their strength and resistance to weathering. Once the strips are prepared, they are shaped into sharp blades, which are affixed to the wire during the manufacturing phase.

Quality control is a vital aspect of the manufacturing process. Factories implement rigorous testing procedures to ensure that the razor wire meets durability and safety standards. This includes tensile strength tests, corrosion resistance assessments, and examination of the sharpness of the blades. Such measures guarantee that the final product will withstand external factors, including harsh environmental conditions and potential tampering efforts.

razor wire factories

Moreover, innovation in razor wire manufacturing has led to the development of designs that not only provide enhanced security but can also be aesthetically pleasing. Spiral razor wire and flat wrap designs are examples of how factories are adapting to meet the needs of different clients, offering products that blend functionality with visual appeal. These innovations broaden the market for razor wire, attracting clients from various sectors, including residential, industrial, and governmental.

Environmental considerations are also becoming a priority for razor wire factories. Many producers are exploring sustainable practices, such as recycling steel materials and reducing waste during the manufacturing process. These efforts reflect a growing trend in the industry toward being more environmentally responsible while still providing effective security solutions.

In summary, razor wire factories are key players in the security landscape, fostering innovation and ensuring quality in their products. As security needs continue to evolve, these factories adapt by implementing advanced manufacturing techniques, focusing on sustainability, and expanding product lines to meet diverse customer demands. The continued growth and development of razor wire manufacturing will undoubtedly play a critical role in enhancing safety and security measures across various sectors globally.

-

Durable Hexagonal Gabion for Erosion Control & Retaining Walls

NewsAug.19,2025

-

Durable & Stylish Roof Tiles for Lasting Home Protection

NewsAug.18,2025

-

Secure & Stylish Fences for Garden, Pool & Property Needs

NewsAug.17,2025

-

Find Your Perfect Fence: Durable, Secure, Affordable Solutions

NewsAug.16,2025

-

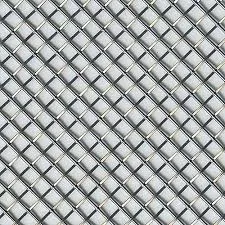

Custom Square Wire Mesh - High Quality, Wholesale Supply

NewsAug.15,2025

-

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

NewsAug.14,2025