-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 11, 2025 09:25 Back to list

Metal Mesh Fabric For Glass Laminated - Durable & Decorative

Why Architects Are Choosing Metal Mesh Fabric For Glass Laminated Facades

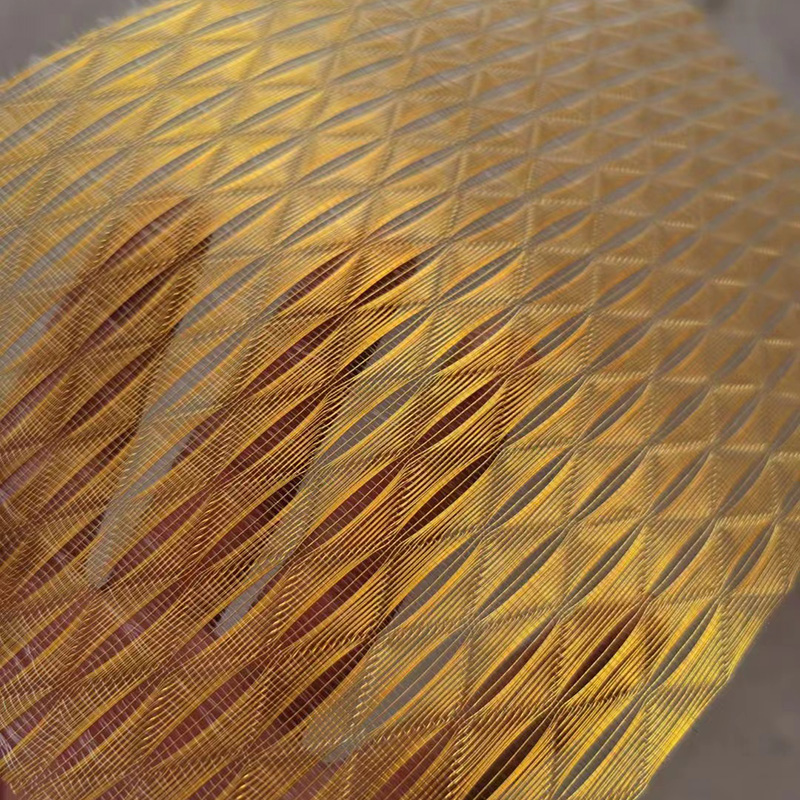

Walk into any forward-looking hotel lobby or sports center lately and you’ll notice it: the subtle shimmer inside laminated glass. It’s not just bling. It’s structure, safety, and a surprising amount of storytelling. As someone who’s followed façade tech for a decade, I can say the momentum is real—designers love how Metal Mesh Fabric For Glass Laminated turns glazing into an active layer of the building.

What’s driving the trend

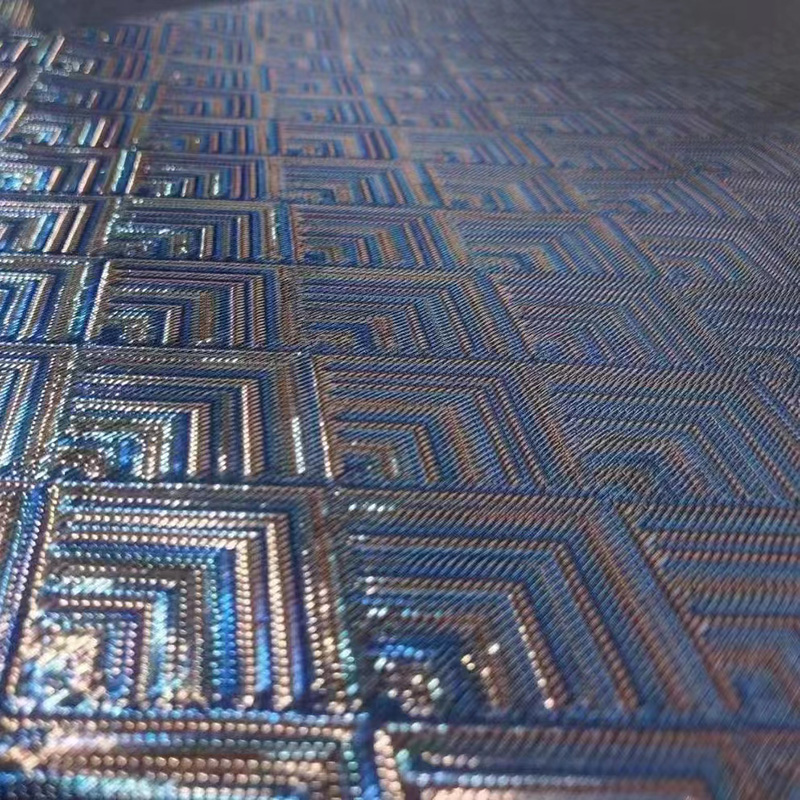

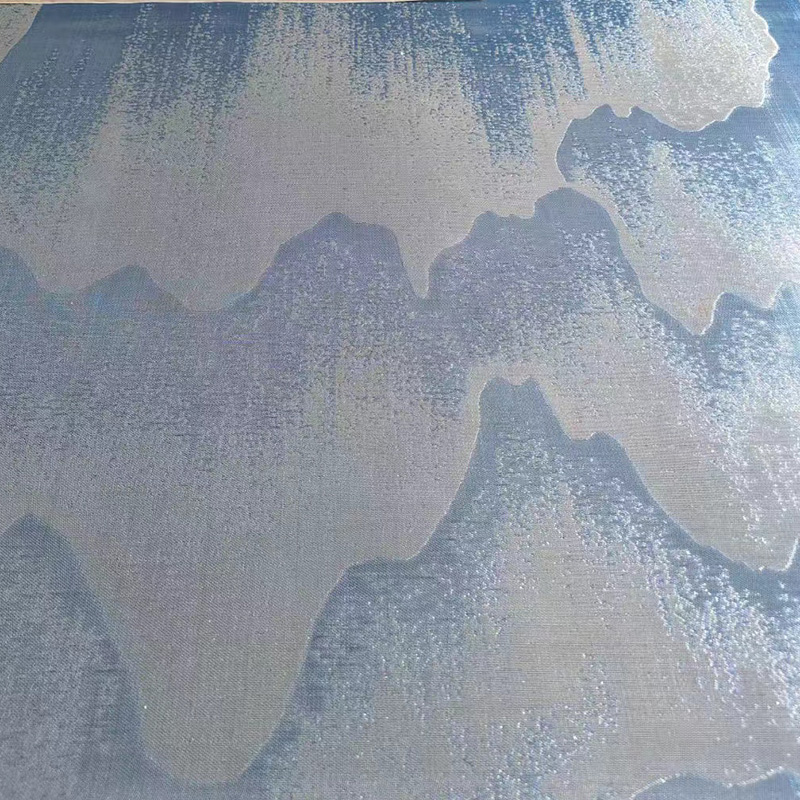

Three things: safety glass regulations tightening worldwide, the need for distinctive yet durable finishes, and (to be honest) Instagram-ready texture. The mesh-in-glass combo offers controlled transparency, glare moderation, and even anti-spall behavior. Many clients tell me they like how each mesh weave gives a distinct personality, which matches the brand vibe without resorting to heavy graphics.

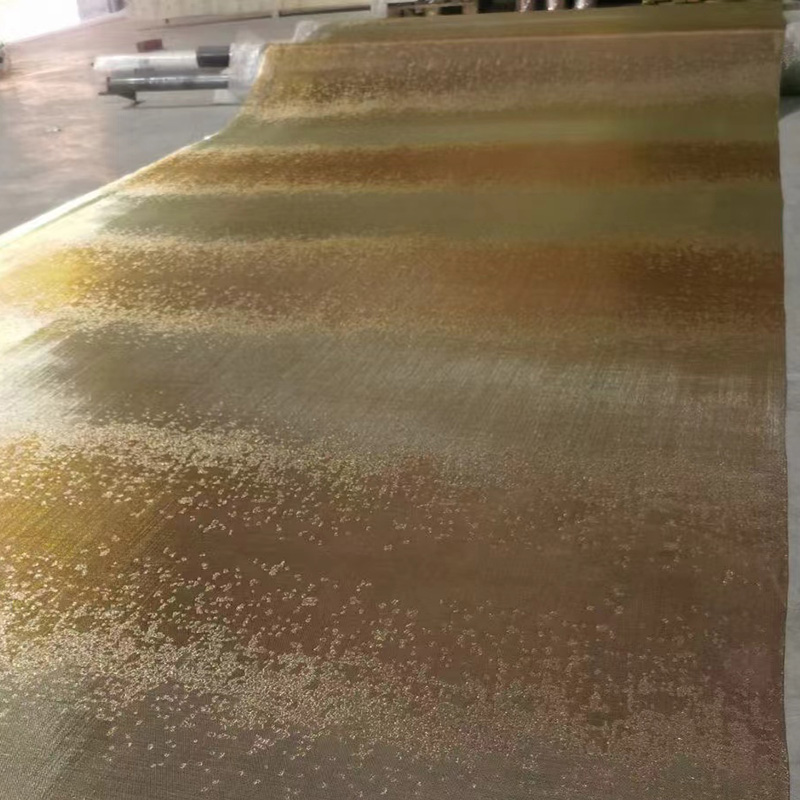

Materials, process, and standards—brief but useful

Typical constructions sandwich stainless steel, bronze, or copper mesh between PVB, EVA, or SGP interlayers and tempered/heat-strengthened glass. The process: mesh selection → surface cleaning → glass cutting and edge prep → interlayer layup → vacuum de-airing → autoclave lamination → inspection. Honestly, the autoclave recipe (time/temp/pressure) is where the craft lives.

- Key standards: ASTM C1172 (laminated architectural glass), ANSI Z97.1 and EN 12600 (safety glazing), EN 14449 (laminated glass), EN 356 (manual attack resistance), ASTM B117 or ISO 9227 (salt spray on exposed meshes). Real-world use may vary by jurisdiction.

- Typical service life: ≈25–35 years interior; ≈15–25 years exterior depending on mesh alloy, coating, and coastal pollution levels.

Product specs (baseline, customizable)

| Mesh alloys | SS304/316L, Phosphor Bronze, Brass, Copper (optional clear/blackened finishes) |

| Weaves | Plain, Twill, Dutch, Crimped, Decorative patterns |

| Wire dia / Aperture | ≈0.2–1.2 mm / ≈0.5–6 mm (pattern dependent) |

| Interlayer options | PVB, EVA, SGP (ionoplast) for higher shear and structural performance |

| Panel thickness | ≈8–28 mm typical; thicker on request |

| Light transmission | ≈20–70% depending on mesh density and glass make-up |

| Origin | South Industrial Zone 07, Anping County, Hebei, China |

Where it shines (use cases)

- Exhibition halls and museums: glare control with curated translucency.

- Hotels, retail, offices: premium lobbies, partitions, balustrades.

- Sports centers and transit hubs: robust, tamper-resistant infill with wayfinding light play.

- Façades and canopies: visual depth, blast/fragment mitigation when specified.

Advantages? Impact safety, dimensional stability, and that “living” texture. A project manager told me, “we get fewer fingerprints and more compliments”—which sounds about right.

Real-world performance (snapshot data)

- Laminate adhesion (peel, 23°C): ≈60–120 N/50 mm, interlayer dependent.

- Salt spray (ASTM B117): 240–1,000 h no red rust on 316L; bronze develops patina as expected.

- Impact: compliant configurations tested to ANSI Z97.1 Cat II/EN 12600 1B1 (spec-specific).

- UV aging (ISO 4892): ΔYI low with UV-stable interlayers; clarify during submittals.

Vendor landscape (quick comparison)

| Vendor type | Strengths | Considerations |

|---|---|---|

| Local glass fabricator | Fast lead times; easy site coordination | Fewer decorative meshes; limited custom weaves |

| Specialist integrator | Envelope engineering; test programs; warranties | Higher cost; longer approvals |

| Anping mesh manufacturer | Broad weave library; custom patterns; competitive pricing | Confirm compliance and third-party tests per project |

Customization and project notes

With Metal Mesh Fabric For Glass Laminated, nearly everything is dialable: weave density, alloy, patina, interlayer tint, even directional orientation for light play. For exterior coastal jobs, I guess 316L plus SGP is a safe baseline. For interiors, designers often pick warm bronze meshes—patina develops gracefully, which clients quite like.

Two quick case notes: a gallery partition using fine copper mesh to mute back-of-house lights (curators were thrilled), and a hotel canopy using crimped 316L for sparkle without glare. Feedback was consistent: “looks expensive, maintains cleanability.”

Certifications and submittals

Ask for mill certs on alloys, interlayer data sheets (PVB/EVA/SGP), and third-party glazing test reports. Many customers say the fastest approvals come with mockups and a short test matrix: impact, adhesion, and accelerated corrosion if exterior. It seems obvious, but spec clarity saves weeks.

References

- ASTM C1172 – Standard Specification for Laminated Architectural Flat Glass. https://www.astm.org/c1172

- ANSI Z97.1 – Safety Glazing Materials Used in Buildings. https://www.ansi.org

- EN 14449 – Glass in building – Laminated glass and laminated safety glass. https://standards.iteh.ai

- EN 356 – Glass in building – Security glazing – Resistance against manual attack. https://standards.iteh.ai

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus. https://www.astm.org/b117

-

Durable Fence Barbed Wire Solutions for Global Security & Agriculture

NewsNov.24,2025

-

Comprehensive Guide to Barbed Fence Wire – Durability, Uses & Innovations

NewsNov.23,2025

-

Barb Wire Price Per Roll – Understanding Costs, Trends & Global Applications

NewsNov.22,2025

-

Stainless Steel Barbed Wire: Durable Security for Global Industries & Relief Efforts

NewsNov.22,2025

-

Comprehensive Guide to Razor Wire Prices: Factors, Trends & Vendors

NewsNov.21,2025

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025