-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 26, 2025 11:40 Back to list

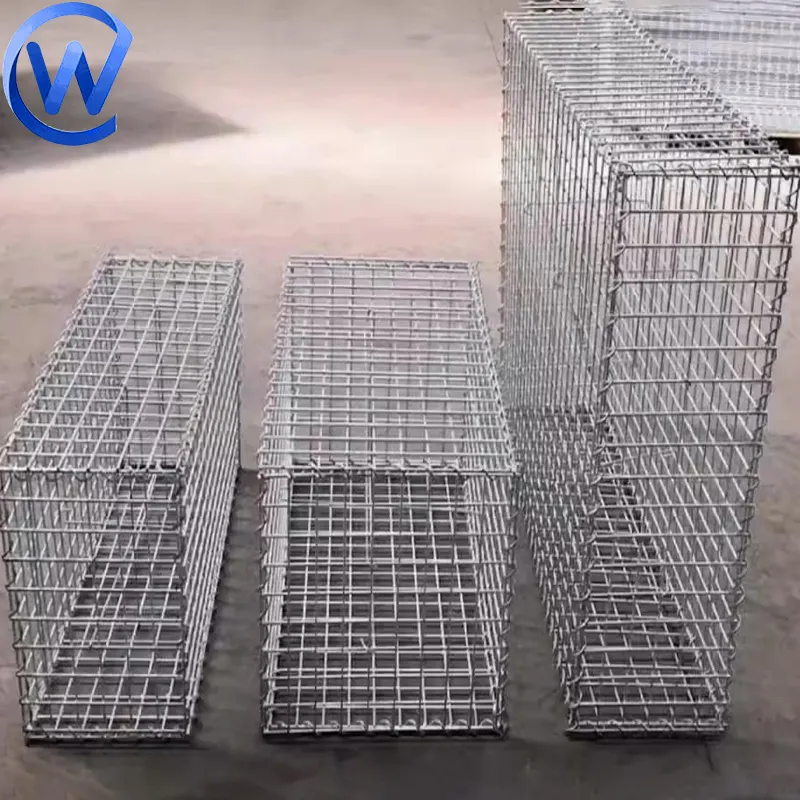

Welded Gabion Baskets – Rigid, Galvanized, Easy Install

Field Notes on Welded Gabion Baskets

If you’ve been around river training jobs or roadside slope work lately, you’ve noticed the same thing I have: contractors moving from woven hex mesh to Welded Gabion systems for cleaner faces, faster assembly, and frankly, prettier walls. Coming out of South Industrial Zone 07, Anping County, Hebei, China, this factory-built basket style has quietly become the default for architectural and light civil retaining. Not hype—just practicality.

What it is, in plain words

A Welded Gabion is a set of flat welded wire panels—front, back, sides, base, and lid—joined with spiral binding wire (or C-rings). After welding, the panels are packed flat; each caged unit is an independent kit, which makes logistics easy and site assembly quick. Many customers say the straight lines help them hit tighter tolerances on façade work, and I’d agree.

Industry trends I’m seeing

- Architectural finishes: hot-dip galvanized + powder topcoat for urban projects.

- Galfan (Zn-5Al-MM) coatings for longer life in coastal zones.

- Pre-cut geotextile liners inside the Welded Gabion to retain fines—saves rework.

Typical specifications

| Item | Spec (≈ ranges; real‑world use may vary) |

|---|---|

| Mesh opening | 50×50, 50×100, 75×75, 100×100 mm |

| Wire diameter | 3.0–5.0 mm (core), 2.2–3.9 mm (PVC/PE after coat ≈ +0.5–1.0 mm) |

| Panel size | 1.0×0.5×0.5 m to 2.0×1.0×1.0 m; custom on request |

| Coatings | Galv. (ASTM A641/EN 10244-2), Hot-dip (ISO 1461), Galfan, Powder topcoat |

| Wire tensile | ≈ 380–550 MPa (low-carbon wire) |

| Fastening | Spiral binders, lacing wire, or stainless C-rings |

| Diaphragms | Every 0.5 m or 1.0 m to prevent bulging |

Process flow (shop-floor reality)

Materials: low-carbon steel wire (e.g., SAE 1008) → resistance spot-welding (to be honest, this is where cheap products skimp) → panel sizing and trimming → coating (pre-galv wire, hot-dip post-fab, or Galfan) → powder coat if specified → assembly with spirals → dimensional/weld shear checks → flat-pack for shipping.

QC/testing: weld shear ≥ 75% of wire UTS (typical shop target), coating thickness checked per ISO 1461/EN 10244-2, salt spray per ASTM B117 for comparative data. Service life? In rural conditions, hot-dip or Galfan baskets often last ≈ 25–60 years; harsh coastal splash zones can be more like 10–25 unless over-specified. Your mileage will vary with fill stone and maintenance.

Applications and where they shine

- Retaining and gravity walls with clean architectural faces.

- Riverbank and culvert inlet protection; energy dissipation aprons.

- Noise barriers and planter walls (architects love uniformity).

- Perimeter security with rock-filled Welded Gabion cages—subtle but robust.

Mini case: a hillside parking expansion near a coastal road used 2.0×1.0×1.0 m Welded Gabion units with Galfan wire and geotextile backing. Crew feedback: assembly was “surprisingly quick” with spirals; alignment held even after heavy compaction behind the wall. No face oil-canning noted after first rainy season.

Vendor landscape (my blunt take)

| Vendor | Region | Coatings | Lead time ≈ | Certs/Tests | Notes |

|---|---|---|---|---|---|

| Anping factory (origin) | Hebei, China | Galv, Hot-dip, Galfan, Powder | 2–4 weeks | ISO 9001, ASTM/EN test reports | Cost-effective; broad size range |

| EU fabricator | Europe | Galfan, Powder | 1–3 weeks | EN/CE docs | Premium finishes; higher cost |

| Trading company | Global | Varies | 3–6 weeks | Mixed | Check weld shear and coating data |

Buyer tip: ask for panel flatness tolerance, weld spacing, and coating thickness certificates upfront. It seems obvious, but it avoids headaches.

Customization and support

Custom mesh (e.g., 75×100 mm), non-standard depths (0.7 m), stainless spirals, and pre-cut geotextiles are common. For coastal jobs, I guess I’d lean to Galfan wire plus powder topcoat. For inland landscaping, zinc galvanized is usually plenty.

Certifications and documentation

Look for ISO 9001 quality systems, material MTRs, coating thickness reports, salt-spray snapshots, and—if needed—third-party inspection. That paper trail makes submittals go smoothly.

Authoritative references

- ASTM A1064/A1064M – Welded wire for reinforcement.

- ASTM A641/A641M – Zinc-coated carbon steel wire.

- ISO 1461 – Hot-dip galvanized coatings on fabricated steel.

- EN 10244-2 – Non-ferrous metallic coatings on steel wire.

- ASTM B117 – Salt spray (fog) testing practice.

- ISO 9001 – Quality management systems.

-

Durable Fence Barbed Wire Solutions for Global Security & Agriculture

NewsNov.24,2025

-

Comprehensive Guide to Barbed Fence Wire – Durability, Uses & Innovations

NewsNov.23,2025

-

Barb Wire Price Per Roll – Understanding Costs, Trends & Global Applications

NewsNov.22,2025

-

Stainless Steel Barbed Wire: Durable Security for Global Industries & Relief Efforts

NewsNov.22,2025

-

Comprehensive Guide to Razor Wire Prices: Factors, Trends & Vendors

NewsNov.21,2025

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025