-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 30, 2024 17:36 Back to list

Customized Welded Mesh Solutions for Diverse Industrial Applications and Projects

Custom Welded Mesh An Overview

Welded mesh, also known as welded wire mesh or welded mesh panels, is a versatile material that serves a multitude of applications across various industries. Its durability, strength, and adaptability make it an ideal choice for a range of construction, agricultural, and industrial needs. Among its various forms, custom welded mesh stands out as a tailored solution to meet specific requirements. This article explores the characteristics, applications, and benefits of custom welded mesh.

Characteristics of Custom Welded Mesh

Custom welded mesh is created by welding together wires at their intersections, forming a sturdy grid-like structure. The wires can be made from a variety of materials, including stainless steel, galvanized steel, and aluminum, depending on the intended use and environmental conditions. The customization aspect allows clients to specify wire diameter, mesh size, and panel dimensions, providing a product that meets their specific needs.

One of the primary advantages of custom welded mesh is its exceptional strength. The welding process ensures that each intersection of wire is robust, creating a barrier that is resistant to forces such as tension and shear. This results in a product that is not only durable but also able to withstand various forms of stress or impact, making it suitable for demanding applications.

Applications of Custom Welded Mesh

Custom welded mesh finds its applications across a variety of sectors

1. Construction and Architecture In the construction industry, it serves as reinforcement for concrete structures, offering enhanced stability and weight distribution. Custom welded mesh panels can also be used in the fabrication of architectural elements, such as safety barriers, partitions, and decorative facades.

2. Agriculture In agricultural settings, welded mesh is often employed for fencing, animal enclosures, and crop protection. Custom designs allow farmers to create enclosures tailored to the size of their livestock or specific crops, ensuring optimal protection against predators and harsh weather.

3. Industrial Use In industrial environments, custom welded mesh is used for safety barriers, machinery guards, and storage solutions. Its ability to provide visibility while maintaining structural integrity makes it a functional choice for factories and warehouses.

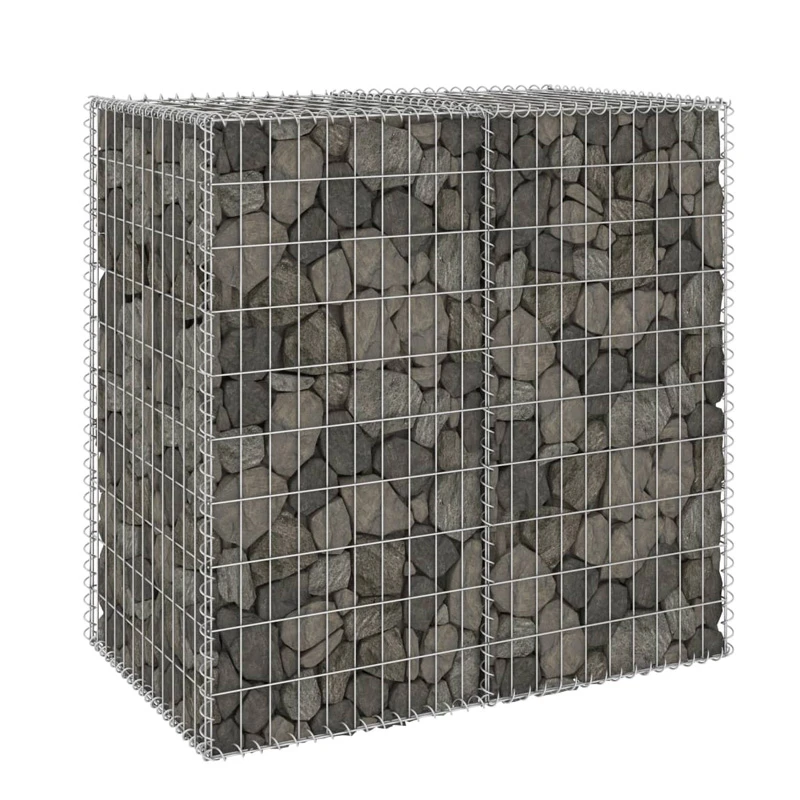

custom welded mesh

4. Landscaping In landscaping projects, welded mesh can be used for trellising, erosion control, and decorative fencing. Customization allows for unique designs that can complement the aesthetic of any garden or outdoor space.

5. Security Applications Custom welded mesh panels are often used in high-security environments, such as prisons or military facilities, where robust barriers are necessary to deter unauthorized access.

Benefits of Custom Welded Mesh

Choosing custom welded mesh over standard options presents several advantages

- Tailored Solutions Custom welded mesh allows for the creation of solutions that are specifically designed to meet individual needs, ensuring that clients receive exactly what they require for their projects.

- Cost-Effectiveness While custom solutions may seem more expensive upfront, they often result in cost savings over time. Custom mesh can reduce waste in production and eliminate the need for additional modifications, ultimately lowering project costs.

- Enhanced Performance Custom designs can enhance the performance of welded mesh. Specific wire diameters and mesh configurations can be employed to improve strength, flexibility, or resistance to corrosion based on the application.

- Aesthetic Appeal Beyond functionality, custom welded mesh can be designed with style in mind. Whether for a residential fence or an artistic installation, the flexibility in design allows for creative freedom in how the mesh will look and perform.

Conclusion

Custom welded mesh is an indispensable material that provides strength, durability, and versatility across numerous applications. Its ability to be tailored to specific needs makes it an attractive choice for industries ranging from construction to agriculture and beyond. As technology and manufacturing processes continue to advance, the possibilities for custom welded mesh will only expand, paving the way for innovative solutions in both industrial and commercial domains. Whether for functional use or aesthetic enhancement, custom welded mesh is a smart investment that brings value and efficiency to any project.

-

Barbed Wire Fence: Durable Security Solutions for Global Agriculture and Industry

NewsNov.19,2025

-

Barbed Wire: Durable & Affordable Security Solutions for Global Applications

NewsNov.18,2025

-

Durable and Cost-Effective Fence Wire Mesh for Farm Sheep – Global Insights & Innovations

NewsNov.18,2025

-

Durable and Cost-Effective Farm Fencing Wire Galvanized | Global Use & Benefits

NewsNov.15,2025

-

Essential Guide to Wire for Fencing: Applications & Innovations

NewsNov.14,2025

-

Durable Fence Security Wire Solutions for Industrial Use | Galvanized Mesh Products

NewsNov.14,2025