-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 12, 2025 11:00 Back to list

Perforated Metal Mesh – Stainless, Custom & Wholesale

Perforated Metal Mesh: Real-World Specs, Use Cases, and Buying Tips

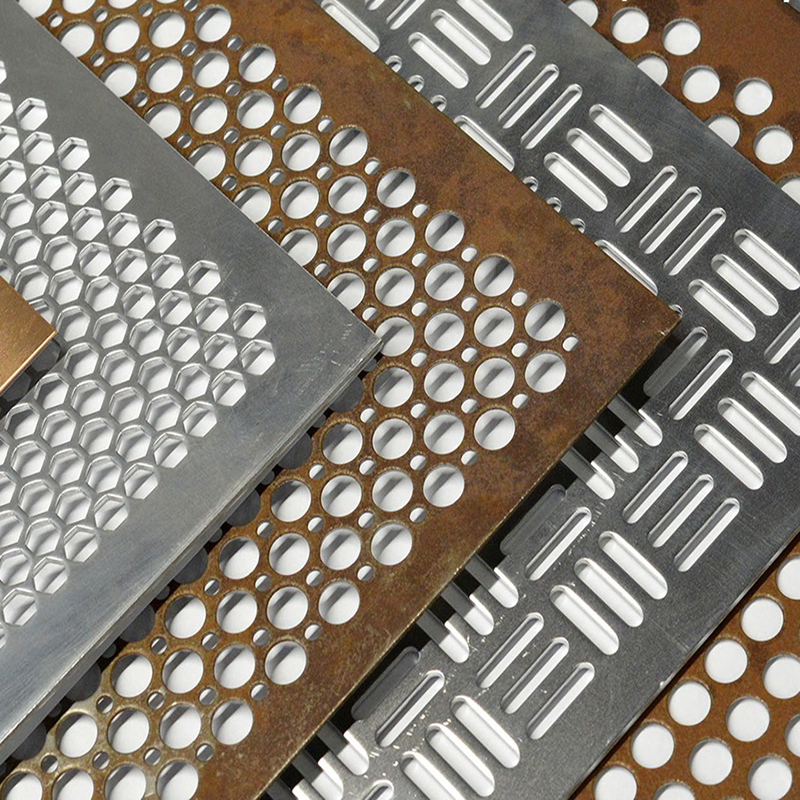

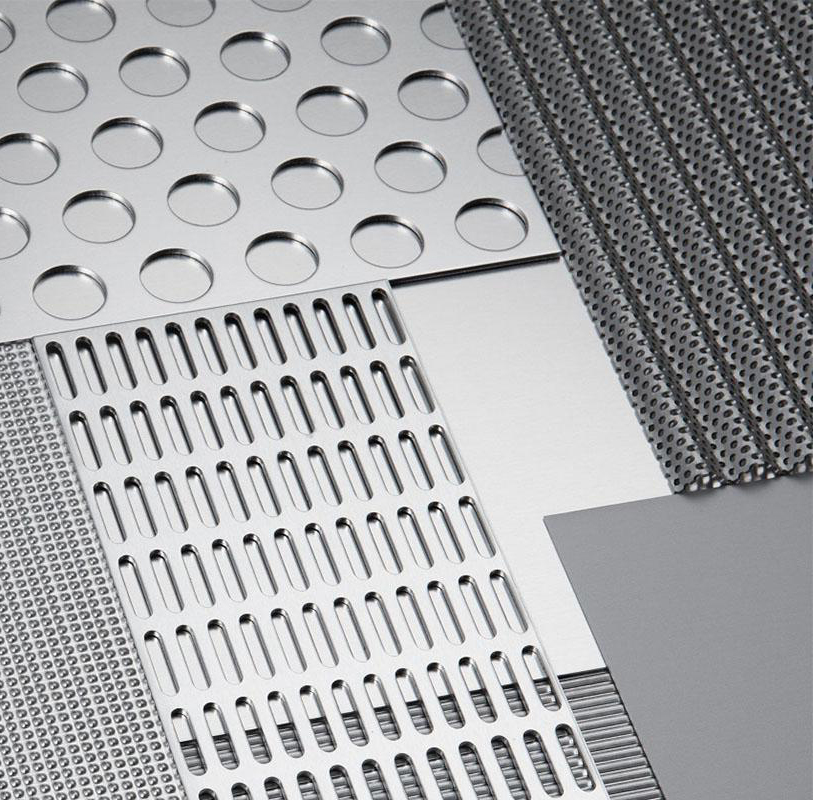

If you’ve ever spec’d perforated metal mesh for a facade or a screening job, you know the drill: hole size, pitch, finish—and a million tiny trade-offs. To be honest, there’s more nuance than most brochures admit. Round-hole patterns remain the workhorse, and yes, pitch means the center-to-center distance. For this supplier, all sheets are on a triangular pitch, which is the sweet spot for strength versus open area. I’ve toured Anping plants before; the tooling racks look like libraries of punch dies.

What’s trending (and why it matters)

- Parametric facades with graded open area for daylighting and ventilation.

- Acoustic skins: perforated faces + mineral wool, tuned NRC (real-world may vary).

- Sustainability: higher recycled content and long-life finishes (PVDF, duplex coats).

- Automation: turret presses and coil-fed lines for tighter tolerances, fewer burrs.

Core specifications (the stuff that gets jobs approved)

Materials run stainless, galvanized steel, aluminum—plus decorative copper/brass on request. In practice, architects default to perforated metal mesh in 304/316 for coastal or food-grade projects, and galvanized (G90/Z275-class) for parking screens.

| Parameter | Option / Range | Notes (≈, real-world may vary) |

|---|---|---|

| Materials | SS 304/316 (ASTM A240); Galv steel (ASTM A653 / EN 10346); Al 1100/3003/5052 (ASTM B209) | Copper/Brass/Corten on request |

| Thickness (t) | ≈0.5–3.0 mm | Heavier gauges by coil program |

| Hole (d) & Pitch (p) | d ≈1.0–20 mm; triangular pitch p ≈1.5d typical | Open area OA ≈ πd²/(2√3·p²) |

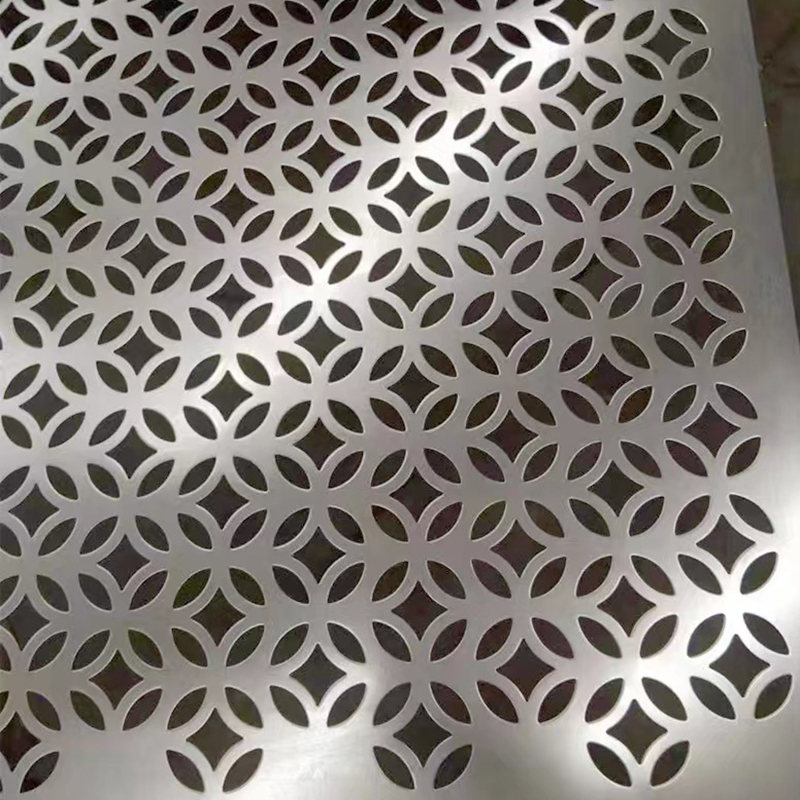

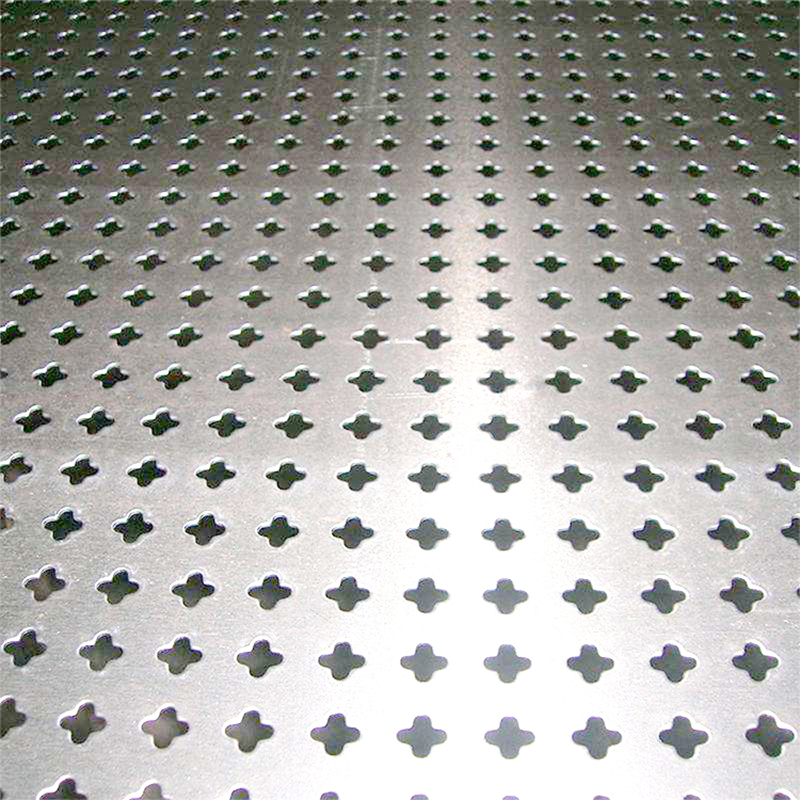

| Patterns | Round (most popular), square, slot, hex, decorative | Custom dies possible |

| Sheet/Coil | Sheets 1000×2000, 1250×2500 mm; Coils 1000–1500 mm width | Cut-to-size on request |

| Finishes | Mill, hot-dip galv, anodized (Al), powder/PVDF | ISO 12944 guidance for corrosivity |

| Tolerances | Per DIN 24041/24042 or IPA recommendations | Hole dia, pitch, edge margins |

Process flow, QA, and service life

- Material selection (coil certs tracked; heat numbers logged).

- Turret/press perforation (triangular pitch tooling), then leveling.

- Deburring and edge trimming; optional forming/flanging.

- Surface treatment: galvanizing, anodizing, or powder/PVDF.

- QC: hole gauge checks, flatness, coating thickness; salt spray per ASTM B117 / ISO 9227.

- Packing: film + crates for export from South Industrial Zone 07, Anping County, Hebei, China.

Typical outdoor life: galv + powder ≈ 15–25 years (C3–C4), 316 SS often 25–30+ years near marine zones—site conditions matter.

Applications and advantages

- Architectural facades, balustrades, sunscreens (daylight + airflow).

- Acoustic enclosures when paired with absorptive backing.

- Filtration, sieving, security screens, HVAC grilles, food equipment.

- Advantages: high strength-to-weight, consistent aperture, easy to fabricate, recyclable.

Vendor comparison (shortlist smarter)

| Vendor | Lead time | Certs | Notables | Typical Price ≈ |

|---|---|---|---|---|

| Anping Manufacturer | 7–12 days MTO | ISO 9001; coating tests to ASTM B117 | Triangular pitch tooling; tight edge margins | $12–$35/m² (pattern/finish dependent) |

| Regional Distributor | 3–5 days (stock) | Varies | Limited patterns; quick pickup | $18–$50/m² |

| Overseas Premium Brand | 4–6 weeks | ISO 9001; EN 13501 fire data | Facade-grade PVDF systems | $40–$90/m² |

Customization and field notes

Most requests are custom: graded OA, special edge margins for clamps, or folded stiffeners. One contractor told me their perforated metal mesh parking facade cut perceived noise by “about 6 dB” after adding mineral wool—informal, but believable. Another food-plant client swapped woven for perforated to stop fraying and cleaning hassles.

Sample test snapshot: G90 galv + 80µm polyester powder reached ≈720 h to first red rust in ASTM B117; PVDF systems often exceed 1,000 h. Always validate with your project’s exposure category (ISO 12944).

Quick buying checklist

- Material + finish for the corrosivity class (C2–C5).

- Hole d, pitch p, open area, and edge margins (clamp zones).

- Flatness and burr spec after coating.

- Certificates: mill, coating thickness, salt spray, and—if relevant—EN 13501 classification for assemblies.

It seems simple—until it isn’t. Get samples punched from the actual coil lot when possible. And if you need a starting point, the Anping line ships globally from Hebei with cut-to-size service and triangular pitch as standard on perforated metal mesh.

Authoritative citations

- ASTM A240/A240M – Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip.

- ASTM A653/A653M – Standard Specification for Steel Sheet, Zinc-Coated (Galvanized).

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ISO 9227 – Corrosion tests in artificial atmospheres – Salt spray tests.

- ISO 12944 – Paints and varnishes — Corrosion protection of steel structures by protective paint systems.

- EN 10346 – Continuously hot-dip coated steel flat products.

- DIN 24041/24042 – Perforated plates tolerances and patterns (round holes, staggered pitch).

- EN 13501-1 – Fire classification of construction products and building elements.

-

Durable Fence Barbed Wire Solutions for Global Security & Agriculture

NewsNov.24,2025

-

Comprehensive Guide to Barbed Fence Wire – Durability, Uses & Innovations

NewsNov.23,2025

-

Barb Wire Price Per Roll – Understanding Costs, Trends & Global Applications

NewsNov.22,2025

-

Stainless Steel Barbed Wire: Durable Security for Global Industries & Relief Efforts

NewsNov.22,2025

-

Comprehensive Guide to Razor Wire Prices: Factors, Trends & Vendors

NewsNov.21,2025

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025