-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 22, 2024 03:03 Back to list

Top Quality Barbed Wire Fence Solutions for Security and Privacy Needs

Understanding Barbed Wire Fences The Role of the Manufacturer

Barbed wire fences have long been a staple in agricultural and security applications, providing an effective and economical solution for boundary marking and protection against intruders. The role of the barbed wire fence manufacturer is critical in ensuring that these fences are durable, reliable, and suited to their intended purpose. In this article, we will delve into the various aspects of barbed wire fences, the manufacturing process, and the importance of quality in the industry.

The Basics of Barbed Wire Fencing

Barbed wire consists of a series of sharp-edged barbs twisted at intervals along a strand of wire. Originally invented in the late 19th century, it revolutionized fencing by providing a simple yet effective deterrent against livestock wandering and unauthorized access to properties. Today, barbed wire is used in various applications, from agriculture to military installations, due to its effectiveness and low cost.

There are different types of barbed wire, including single-strand barbed wire, double-strand barbed wire, and high-tensile options. The choice of barbed wire often depends on the specific needs of the user, such as the type of livestock to be contained or the level of security desired.

The Manufacturing Process

The manufacturing of barbed wire involves several key steps to ensure the final product meets industry standards and customer expectations

.1. Material Selection The primary material used in barbed wire production is steel due to its strength and durability. Manufacturers may use galvanized steel to enhance resistance to rust and corrosion, ultimately extending the lifespan of the fence.

2. Wire Drawing The process begins with wire drawing, where large coils of steel are pulled through a series of dies to achieve the desired thickness. This step is crucial, as the thickness of the wire directly impacts the strength and flexibility of the finished product.

barbed wire fence manufacturer

3. Barb Formation Next, the barbs are created. This is typically done using automated machines that cut and twist the wire into barbed shapes at specified intervals. The precision of this process affects the fence's effectiveness; well-placed barbs ensure a strong deterrent against trespassers and livestock.

4. Wire Twisting After the barbs are attached, the wire strands are twisted together to form the finished barbed wire. This twisting process is essential for maintaining structural integrity and is often executed with machinery designed to ensure consistent tension.

5. Galvanization To further enhance protection against the elements, many manufacturers galvanize barbed wire, dipping it in molten zinc. This process creates a protective coating that prevents rusting, thereby increasing the fence's longevity.

6. Quality Control Before reaching the market, the finished product undergoes stringent quality control inspections. This includes checking for defects in the wire, ensuring the barbs are sharp and properly spaced, and verifying that the overall strength meets regulatory standards.

Importance of Quality and Standards

The market for barbed wire fencing is competitive, which makes the role of the manufacturer paramount. Consumers demand high-quality products that perform well under various conditions. Subpar materials or manufacturing processes can lead to fences that fail prematurely, leading to costly replacements and potential security breaches.

Manufacturers often adhere to international standards, such as ASTM (American Society for Testing and Materials) certifications, which dictate specifications for wire diameter, tensile strength, and galvanization quality. By meeting these standards, manufacturers can assure customers of the reliability and safety of their products.

Conclusion

Barbed wire fences play a vital role in modern agriculture and security. The barbed wire fence manufacturer is key to this industry, providing the necessary expertise and attention to detail required to produce high-quality fencing solutions. From material selection and manufacturing processes to quality control and adherence to industry standards, the journey of barbed wire from raw material to finished product is a testament to the craftsmanship involved in its production. As demand continues to grow, manufacturers who prioritize quality and innovation will lead the way in this essential sector, ensuring that fences remain a reliable option for protection and containment for years to come.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

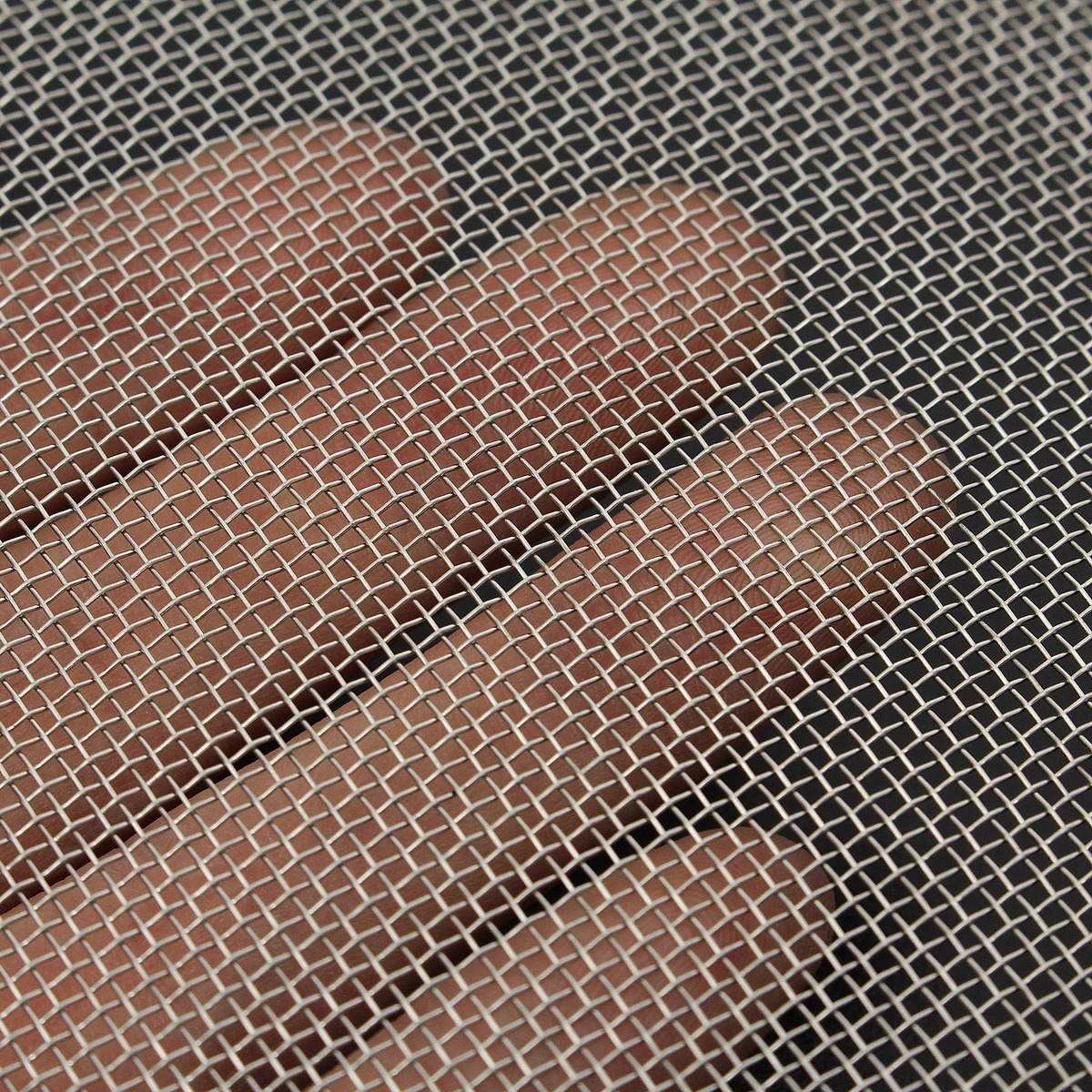

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025