-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 19, 2024 22:46 Back to list

concrete welded wire mesh manufacturer

The Importance of Concrete Welded Wire Mesh in Modern Construction

Concrete welded wire mesh has become an essential component in the construction industry, playing a crucial role in enhancing the structural integrity of various projects. As a leading manufacturer in this domain, understanding the significance of welded wire mesh in concrete construction is vital for ensuring durability, safety, and cost-effectiveness.

What is Concrete Welded Wire Mesh?

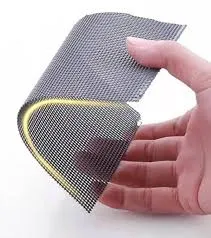

Concrete welded wire mesh consists of a network of steel wires that are welded together at intersections, forming a grid-like structure. This mesh is typically made from high-quality steel, offering superior strength and stability. It is available in various sizes, gauges, and configurations to meet the diverse needs of construction projects ranging from residential buildings to large-scale infrastructure.

Application Areas

The applications of concrete welded wire mesh are vast. It is predominantly used in

1. Reinforced Concrete Slabs Wire mesh is incorporated into concrete slabs to prevent cracking and enhance load-bearing capacity. By distributing loads evenly, it minimizes the risk of structural failure.

2. Road and Pavement Construction In roadways and pavements, welded wire mesh provides reinforcement that withstands heavy traffic and changing weather conditions, thus extending the lifespan of the surface.

3. Walls and Foundations Concrete welded wire mesh is utilized in constructing walls and foundations, providing additional strength and stability, particularly in areas susceptible to earthquakes or soil settlement.

Advantages of Using Welded Wire Mesh

concrete welded wire mesh manufacturer

1. Enhanced Strength and Durability The primary advantage of using welded wire mesh in concrete construction is its ability to increase the tensile strength of the concrete. This reinforcement helps resist cracking and other forms of structural degradation over time.

2. Cost-Effectiveness While the initial investment in welded wire mesh can be higher than using conventional rebar, its long-term benefits, including reduced repair and maintenance costs, make it a cost-effective solution.

3. Ease of Installation Welded wire mesh is easier and faster to install compared to traditional reinforcement methods. This efficiency can lead to reduced labor costs and shorter project timelines.

4. Versatility Available in a range of specifications, welded wire mesh can be tailored to suit various construction needs, making it a versatile choice for different types of projects.

Quality and Standards

As a reputable concrete welded wire mesh manufacturer, it is essential to adhere to industry standards and certifications. The quality of the wire mesh plays a significant role in its performance. High tensile strength and proper welding techniques ensure that the mesh can withstand the demands of concrete structures without compromising safety.

Environmental Considerations

The construction industry is increasingly focusing on sustainable practices. Using welded wire mesh can contribute to environmentally-friendly building methods. Its longevity reduces the need for frequent repairs and replacements, minimizing waste. Additionally, many manufacturers are adopting eco-friendly processes to reduce their carbon footprint, ensuring that the production of welded wire mesh aligns with global sustainability goals.

Conclusion

Concrete welded wire mesh is an indispensable material in modern construction, offering enhanced strength, durability, and cost-effectiveness. As a noteworthy component in reinforced concrete applications, it contributes significantly to the safety and longevity of various structures. With proper manufacturing standards and a focus on sustainability, welded wire mesh stands out as a reliable choice for builders, architects, and engineers alike. As the construction industry continues to evolve, the importance of quality and innovation in products like welded wire mesh will remain paramount, ensuring that we build stronger and safer communities for the future.

-

3D Curved Welded Wire Mesh Fence | Secure & Durable Panels

NewsAug.29,2025

-

Stainless Steel Angle Factories: Premium Quality & Custom Solutions

NewsAug.28,2025

-

Heavy-Duty Stackable Storage Cages for Efficient Warehouse Storage

NewsAug.27,2025

-

Stainless Steel Wire Mesh: Durable & Corrosion-Resistant Rolls

NewsAug.26,2025

-

Durable Fences: Garden, Pool, Metal & Security Solutions

NewsAug.25,2025

-

Perforated Metal Mesh Sheets: Custom & Wholesale Solutions

NewsAug.24,2025