-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 14, 2025 08:20 Back to list

Durable Hexagonal Gabion Baskets for Erosion Control & Retaining Walls

Understanding Hexagonal Gabion: A B2B Perspective on Erosion Control and Civil Engineering

In the demanding world of civil engineering, infrastructure development, and environmental protection, the integrity and durability of construction materials are paramount. Among the most versatile and robust solutions for earth retention, erosion control, and hydraulic works is the Hexagonal Gabion. This engineered structure, composed of double-twisted hexagonal wire mesh, forms permeable baskets that are filled with inert materials like stone, rock, or concrete, creating a flexible, monolithic block. Its application spans across various sectors, offering both structural stability and ecological benefits.

Our focus here is to provide a comprehensive B2B insight into these essential engineering components, detailing their manufacturing, technical specifications, application advantages, and strategic deployment in modern projects. We aim to equip decision-makers and technical professionals with the necessary knowledge to select optimal gabion solutions for their specific operational challenges.

Manufacturing Process: Precision and Durability in Every Mesh

The production of a high-quality Hexagonal Gabion is a meticulously controlled process, ensuring compliance with international standards such as ASTM A975-97 and EN 10223-3. This process guarantees the strength, flexibility, and longevity essential for demanding applications.

Key Stages of Manufacturing:

- Wire Drawing and Material Selection: The foundation is high-tensile steel wire, typically low-carbon steel, selected for its ductility and strength. This wire is drawn to specific diameters, ranging from 2.0 mm to 4.0 mm, depending on the required mesh strength. Common materials include galvanized steel, Galfan (Zn-5%Al-MM alloy) coated steel, or PVC-coated galvanized/Galfan wire for enhanced corrosion resistance.

-

Coating Application (Galvanization/Galfan/PVC):

- Hot-Dip Galvanization: Wires are passed through molten zinc, creating a protective zinc layer (typically 245-290 g/m²) that acts as a sacrificial anode against corrosion.

- Galfan Coating: A zinc-aluminum (95% Zn, 5% Al) alloy coating is applied, offering superior corrosion resistance—often 2-3 times that of standard galvanization—due to its dense, uniform structure.

- PVC Coating: For extreme environments (e.g., marine, highly acidic soils), a thick PVC coating (approx. 0.5 mm) is extruded over galvanized or Galfan wires, providing an additional barrier against chemical degradation and abrasion.

- Double-Twist Weaving: Specialized machinery intricately weaves the coated wires into a hexagonal mesh pattern. The double-twist ensures that if a single wire breaks, the integrity of the mesh is maintained, preventing unraveling. This mechanical process creates a highly flexible and robust panel.

- Selvedging/Edge Wiring: All edges of the gabion panels (diaphragms, ends, and main body) are reinforced with a heavier gauge wire, known as selvedge wire. This strengthens the structure, facilitates assembly, and prevents deformation under load.

- Cutting, Folding, and Packaging: The woven mesh is cut to precise dimensions for the desired gabion unit size. Panels are then folded flat for efficient transport and storage, significantly reducing shipping volumes. Each unit is inspected to ensure it meets dimensional and quality standards.

Testing Standards and Service Life:

Our Hexagonal Gabion products undergo rigorous testing to comply with international standards such as ISO 9001 for quality management, and specific material and product standards like ASTM A975-97 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses) and EN 10223-3 (Steel wire and wire products for fencing and netting – Hexagonal steel wire netting for civil engineering purposes). These tests cover wire tensile strength, coating adherence, mesh pull-apart resistance, and overall structural integrity.

Depending on the coating type and environmental conditions, the service life of a Hexagonal Gabion can vary significantly:

- Galvanized Gabions: Typically 10-25 years in non-aggressive environments.

- Galfan Coated Gabions: 25-50+ years, even in moderately aggressive conditions.

- PVC Coated Gabions: 50-100+ years in highly corrosive or abrasive environments.

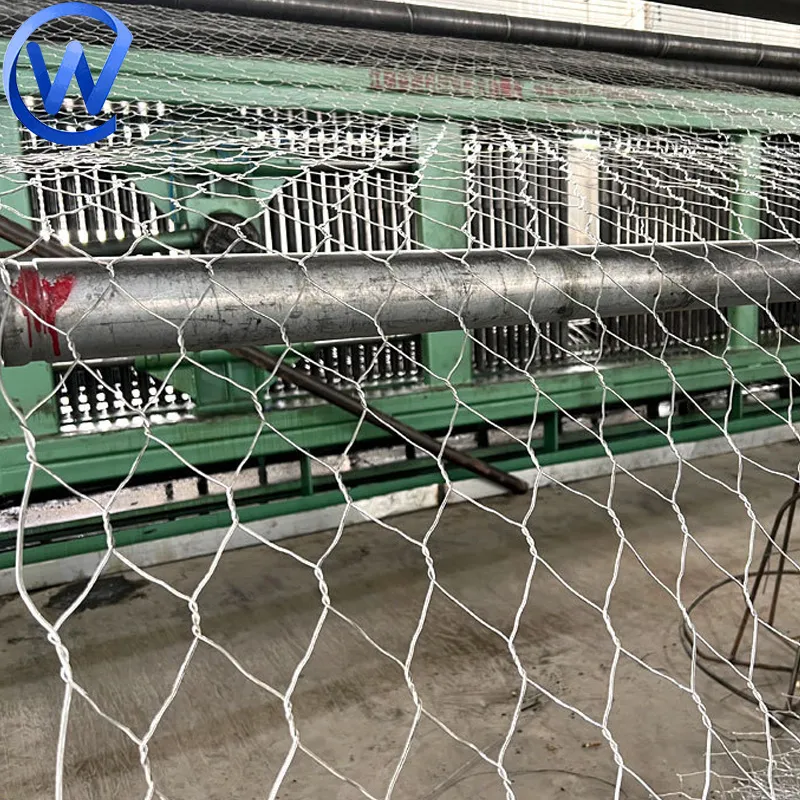

Figure 1: Manufacturing line for high-durability hexagonal mesh.

Technical Specifications and Parameters

The performance of a Hexagonal Gabion is intrinsically linked to its precise technical specifications. Understanding these parameters is crucial for engineers and project managers to ensure structural integrity and compliance with design requirements.

Standard Gabion Specifications:

| Parameter | Details / Range | Relevant Standard |

|---|---|---|

| Mesh Type | Double-Twisted Hexagonal | ASTM A975-97, EN 10223-3 |

| Mesh Opening Size (mm) | 60x80, 80x100, 100x120, 120x150 | ASTM A975-97 |

| Wire Diameter (Mesh Wire) | 2.0 mm - 4.0 mm | ASTM A641, EN 10218-2 |

| Wire Diameter (Selvedge Wire) | Typically 0.5 mm - 1.0 mm thicker than mesh wire | ASTM A641, EN 10218-2 |

| Tensile Strength (Wire) | 380-550 MPa (approx. 55-80 ksi) | ASTM A641, EN 10218-2 |

| Coating Type | Hot-dip Galvanized, Galfan (Zn-5%Al-MM), PVC Coated | ASTM A90/A90M, ASTM A856/A856M, EN 10244-2 |

| Coating Weight (Galvanized) | Min. 245 g/m² to 290 g/m² | ASTM A90/A90M, EN 10244-2 Class A |

| PVC Coating Thickness | Nominal 0.5 mm (min. 0.4 mm) | EN 10245-1 |

| Standard Box Dimensions (L x W x H) | 2x1x1m, 3x1x1m, 4x1x1m, 2x1x0.5m, etc. (custom sizes available) | Manufacturer Specific |

The double-twist weave is critical for the gabion's performance, providing a non-raveling mesh that maintains its integrity even if individual wires are cut. This flexibility allows the structures to tolerate differential settlement without loss of efficiency, a key advantage in geologically active or soft ground areas.

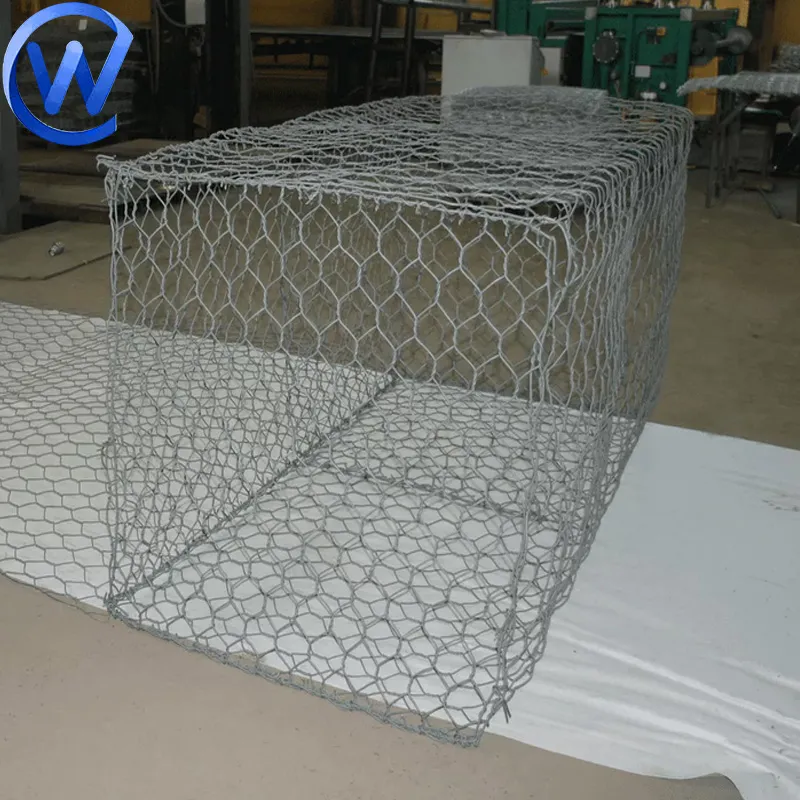

Figure 2: Stacked gabion units ready for deployment.

Industry Trends and Application Scenarios

The demand for robust, environmentally friendly, and cost-effective engineering solutions drives the continuous evolution of the Hexagonal Gabion market. Key trends include the increasing adoption of sustainable construction practices, a focus on climate change adaptation, and the integration of gabions into bio-engineering projects.

Target Industries and Typical Applications:

-

Civil Engineering & Infrastructure:

Used extensively for retaining walls, bridge abutments, culvert headwalls, and general earth stabilization. Gabions provide structural support while allowing drainage, preventing hydrostatic pressure buildup. For instance, in highway construction, gabion retaining walls are often preferred for their flexibility and cost-effectiveness compared to rigid concrete structures.

-

River & Coastal Engineering (Water Supply & Drainage):

Critical for river bank protection, channel lining, weirs, and scour protection. Their permeable nature dissipates energy from flowing water, reducing erosion. PVC-coated gabions are particularly effective in saltwater or chemically aggressive aquatic environments, offering superior corrosion resistance and extended service life, safeguarding vital water infrastructure.

-

Mining & Quarrying:

Employed for slope stabilization, protection of haul roads, and erosion control around tailings dams. Their robust construction can withstand harsh conditions and seismic activity common in mining regions.

-

Landscaping & Architecture:

Increasingly utilized for aesthetic purposes, such as façade cladding, decorative walls, and noise barriers, blending natural aesthetics with functional engineering.

-

Environmental Remediation:

Used in wetland restoration, bio-filtration systems, and erosion control in sensitive ecological areas, demonstrating excellent ecological compatibility.

Figure 3: Gabion retaining wall in a civil engineering project.

Technical Advantages and Performance Metrics

The inherent design and material properties of Hexagonal Gabion structures confer several distinct advantages, making them a preferred choice for demanding engineering applications.

Key Advantages:

- Flexibility and Adaptability: Unlike rigid concrete structures, gabions can tolerate significant differential settlement without cracking or structural failure. This makes them ideal for areas with unstable ground conditions, seismic activity, or where minor ground movement is anticipated. This inherent flexibility contributes to their long-term stability and reduced maintenance costs.

- Permeability and Drainage: The stone-filled mesh allows free passage of water, preventing hydrostatic pressure buildup behind the structure. This eliminates the need for complex drainage systems, simplifying design and construction, while enhancing overall stability. This passive drainage also contributes to energy saving by reducing reliance on active dewatering systems in certain scenarios.

- Corrosion Resistance & Durability: With advanced coating options like Galfan and PVC, gabions offer exceptional corrosion resistance, extending their service life in aggressive environments. Galfan coating, for instance, provides cathodic protection and forms a stable passive layer, significantly outperforming standard galvanization. This directly translates to enhanced durability, especially critical in coastal or industrial settings where chemical exposure is a concern.

- Environmental Friendliness: Gabions use readily available, often locally sourced, inert fill materials, minimizing transportation costs and carbon footprint. They also support natural vegetation growth over time, integrating seamlessly into the landscape and promoting ecological restoration, particularly in bio-engineering applications.

- Cost-Effectiveness: The simplicity of construction, use of local fill, reduced need for specialized equipment, and long service life make gabions a highly cost-effective solution compared to traditional concrete or masonry structures, offering significant long-term ROI.

- Ease of Construction: Gabion units are typically supplied flat-packed and assembled on-site. Installation requires minimal skilled labor and basic equipment, accelerating project timelines.

Figure 4: Detailed view of the double-twist hexagonal mesh.

Vendor Comparison and Customized Solutions

Selecting the right supplier for Hexagonal Gabion systems is crucial for project success. A robust vendor offers not only high-quality products but also comprehensive technical support, customization capabilities, and a reliable supply chain.

Key Factors in Vendor Comparison:

| Feature | Our Offering | Typical Competitor (Variable) |

|---|---|---|

| Wire Coating Options | Hot-Dip Galvanized, Galfan (Zn-5%Al-MM), PVC Over Galvanized/Galfan | Often only Hot-Dip Galvanized; limited Galfan/PVC |

| Compliance & Certifications | ISO 9001, ASTM A975, EN 10223-3 (Verified) | May claim compliance without clear certification; lesser known standards |

| Customization Capabilities | Full customization: mesh size, wire diameter, coating, panel dimensions, bespoke designs | Limited to standard sizes and materials |

| Technical Support & Design Assistance | Dedicated engineering team, site support, design optimization advice | Basic product information only; little to no design support |

| Lead Time & Logistics | Streamlined production, global logistics network for timely delivery | Potentially longer lead times, less flexible shipping |

| Warranty & After-Sales | Comprehensive warranty up to 10 years (material/coating), responsive support | Limited or unclear warranty, minimal after-sales support |

Customized Solutions: Tailored to Project Needs

Recognizing that every project presents unique challenges, we offer extensive customization options for Hexagonal Gabion systems. This includes:

- Non-Standard Dimensions: Production of gabion boxes or mattresses in specific lengths, widths, or heights to fit unique site geometries or aesthetic requirements.

- Varied Wire Gauges: Custom wire diameters for mesh and selvedge wires, optimized for specific structural loads or expected service life in critical applications.

- Specialized Coatings: Beyond standard options, we can explore niche coating solutions for highly specialized environmental conditions, working with our R&D team.

- Integrated Components: Design and supply of gabions with integrated lifting loops, internal bracing, or geotextile liners for specific hydraulic or geotechnical functions.

Our engineering team collaborates closely with clients from conceptualization to deployment, ensuring that customized gabion solutions seamlessly integrate into the broader project design, delivering optimal performance and longevity.

Application Case Studies: Proven Performance in Diverse Environments

The efficacy and versatility of the Hexagonal Gabion have been demonstrated across countless projects worldwide. Here are examples showcasing its application and benefits:

Case Study 1: River Bank Protection in an Arid Region

- Challenge: A major river in an arid region experienced severe bank erosion during seasonal floods, threatening agricultural land and critical infrastructure. Traditional concrete solutions were deemed too rigid and costly.

- Solution: Extensive use of Galfan-coated Hexagonal Gabion mattresses and baskets to line the riverbanks and construct protective groynes. The flexibility of the gabions allowed them to conform to minor ground settlements, while the Galfan coating ensured excellent corrosion resistance against the brackish water and high temperatures.

- Outcome: The gabion structures successfully prevented further erosion, stabilized the banks, and allowed for the re-establishment of riparian vegetation within the gabion fill, enhancing local biodiversity and long-term stability. The project has performed flawlessly for over 15 years, significantly exceeding initial expectations for durability in challenging conditions.

Case Study 2: Highway Embankment Stabilization in a Seismic Zone

- Challenge: Construction of a new highway required stabilizing a steep embankment in a seismically active area. The design needed to accommodate potential ground movements without structural failure.

- Solution: A tiered retaining wall system was designed using large PVC-coated Hexagonal Gabion baskets (3x1x1m units). The PVC coating provided an additional layer of protection against potential chemical attacks from the soil and long-term abrasion, while the inherent flexibility of the gabions was critical for seismic resilience.

- Outcome: The gabion wall successfully retained the embankment, proving its stability during minor seismic tremors. The structure integrated well with the surrounding landscape, allowing for natural drainage and minimizing environmental impact. Our client reported significant cost savings compared to alternative rigid retaining systems.

Figure 5: Completed gabion structure in an erosion control application.

Frequently Asked Questions (FAQ)

- Q: What is the primary difference between gabion baskets and gabion mattresses?

- A: Gabion baskets are typically cube-shaped or rectangular, with heights generally equal to or greater than their width, used primarily for retaining walls, abutments, and mass gravity structures. Gabion mattresses (also known as Reno mattresses) are wider and longer with a comparatively shallow height (e.g., 0.17m to 0.5m high), designed for channel lining, scour protection, and bank stabilization where a flexible, erosion-resistant surface is required. Both utilize Hexagonal Gabion double-twist mesh.

- Q: How do gabions handle seismic activity?

- A: Gabions are inherently flexible structures due to their wire mesh construction and granular fill. This allows them to deform and adapt to ground movements, including differential settlements and seismic stresses, without fracturing, which is a significant advantage over rigid structures like reinforced concrete walls. The double-twist mesh maintains integrity even if some wires are damaged.

- Q: Can gabions be vegetated for ecological integration?

- A: Absolutely. Gabions are highly compatible with bio-engineering techniques. Their porous nature allows soil to accumulate within the rock fill over time, creating a suitable environment for vegetation growth. This not only enhances the aesthetic appeal but also adds to the long-term stability and ecological value of the structure, promoting natural habitat restoration.

- Q: What are the typical lead times for large orders?

- A: Lead times vary based on order volume, customization requirements, and current production schedules. For standard Hexagonal Gabion units, typical lead times range from 2 to 4 weeks for production, followed by transit time. For highly customized or exceptionally large orders, lead times will be confirmed upon detailed project assessment. We maintain a robust supply chain and efficient manufacturing processes to meet tight project deadlines.

- Q: What warranty is provided with your gabion products?

- A: We offer comprehensive warranties on our Hexagonal Gabion products, typically covering manufacturing defects and coating integrity for up to 10 years, depending on the specific product and coating type (e.g., Galfan and PVC coatings often carry longer warranties due to their superior performance). Detailed warranty statements are provided with each quotation, outlining terms and conditions. Our commitment extends to robust after-sales support to address any concerns.

Commitment to Trust and Support

Our dedication to providing high-quality Hexagonal Gabion solutions extends beyond product delivery. We emphasize trust, transparency, and unwavering customer support.

Lead Time and Fulfillment:

We operate a highly efficient manufacturing facility combined with a globally optimized logistics network. This ensures that whether your project requires standard gabion baskets or highly customized solutions, we can provide reliable lead times and on-schedule delivery. Our planning team works closely with clients to synchronize production with project milestones.

Warranty and After-Sales Support:

Each Hexagonal Gabion product is backed by an industry-leading warranty, covering material integrity and coating performance. Our commitment does not end at sale; our dedicated after-sales support team is available to provide technical assistance, address operational queries, and offer expert advice throughout the lifespan of your project. We believe in building long-term partnerships through consistent product excellence and responsive service.

For detailed inquiries, technical consultations, or to request a tailored quotation for your specific project needs, please do not hesitate to contact our expert sales and engineering teams. We are poised to support your next infrastructure challenge with proven, reliable gabion solutions.

References:

- ASTM A975-97. Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With PVC Coating). ASTM International.

- EN 10223-3:2013. Steel wire and wire products for fencing and netting - Part 3: Hexagonal steel wire netting for civil engineering purposes. European Committee for Standardization.

- Maccaferri. Gabions and Reno Mattresses: Flexible and Permeable Structures. Technical Guide.

- FHWA. Gabion Retaining Walls and Soil Retaining Systems. Federal Highway Administration Geotechnical Engineering Circular No. 10.

- Bergado, D. T., Chai, J. C., & Alfaro, M. C. (2000). Reinforced soil engineering: From highway to marine structures. CRC press. (Specific sections on gabion applications).

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025

-

Barbed Wire Fence: Durable Security Solutions for Global Agriculture and Industry

NewsNov.19,2025

-

Barbed Wire: Durable & Affordable Security Solutions for Global Applications

NewsNov.18,2025

-

Durable and Cost-Effective Fence Wire Mesh for Farm Sheep – Global Insights & Innovations

NewsNov.18,2025

-

Durable and Cost-Effective Farm Fencing Wire Galvanized | Global Use & Benefits

NewsNov.15,2025

-

Essential Guide to Wire for Fencing: Applications & Innovations

NewsNov.14,2025