-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 05, 2024 06:03 Back to list

Durable Wire Mesh Screens for Heavy-Duty Industrial Applications and Custom Solutions

Understanding Heavy Duty Wire Mesh Screens A Comprehensive Overview

When it comes to industrial applications, the importance of durable and reliable materials cannot be overstated. Among these, heavy duty wire mesh screens play a crucial role in various sectors, including mining, construction, and agricultural industries. This article delves into the significance of heavy duty wire mesh screens and the key factors to consider when choosing a manufacturer.

What are Heavy Duty Wire Mesh Screens?

Heavy duty wire mesh screens are woven screens made from strong materials designed to endure high levels of stress and impact. These screens are typically made from stainless steel, galvanized steel, or other robust materials, providing significant strength and resistance to abrasion, corrosion, and deformation. Their primary function is to separate materials based on size, ensuring efficient processing and screening of liquids and solids in various applications.

Applications of Heavy Duty Wire Mesh Screens

Heavy duty wire mesh screens are utilized in numerous industries for diverse functions. Here are a few applications

1. Mining and Aggregates In the mining sector, these screens are essential for sieving and extracting minerals, withstanding the abrasive nature of the materials. They help maintain efficient operations by ensuring that only the desired particle sizes pass through.

2. Construction In construction, heavy duty wire mesh screens are employed for sifting sand, gravel, and other materials. They aid in quality control by allowing fine materials to fall through while retaining larger aggregates.

3. Agriculture Farmers utilize wire mesh screens for sifting soil, compost, and other organic materials, helping to create ideal conditions for crop growth. They are also employed in grain storage to ventilate and protect stored grains from pests.

4. Environmental Applications Heavy duty wire mesh is vital in waste management and filtration systems. They help separate solid waste materials from liquids, ensuring effective recycling processes.

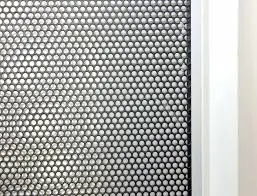

heavy duty wire mesh screens manufacturer

Choosing the Right Manufacturer

Selecting the right manufacturer for heavy duty wire mesh screens can significantly impact your operation’s efficiency and overall quality. Here are essential factors to consider

1. Quality Assurance Look for manufacturers who adhere to strict quality control processes. Certifications for quality management systems such as ISO 9001 are key indicators of reliability and product quality.

2. Material Specification Ensure the manufacturer provides products made from high-grade materials suitable for your specific application. The choice of material will greatly influence the durability and performance of the wire mesh screens.

3. Customization Options Every application has unique requirements. A good manufacturer should offer customization options, allowing you to obtain screens tailored to your specific dimensions, mesh sizes, and materials.

4. Industry Experience Opt for manufacturers with extensive experience in producing heavy duty wire mesh screens. Their knowledge of industry-specific challenges can help in designing products that meet your needs effectively.

5. Customer Support Reliable customer support is crucial, as it ensures you have assistance with installation, maintenance, and any issues that may arise. Manufacturers who prioritize customer service often foster long-term partnerships.

6. Cost-Effectiveness While it’s essential to stay within budget, prioritize quality over the lowest price. Cheaply made screens may lead to frequent replacements and downtime, ultimately costing more in the long run.

Conclusion

Heavy duty wire mesh screens are indispensable in numerous industrial applications, combining durability with functionality. By understanding their significance and carefully selecting a reputable manufacturer, businesses can enhance their operational efficiency and productivity. Investing in high-quality wire mesh screens not only contributes to better material handling but also impacts the overall success of industrial processes. As you navigate your options, prioritize quality, customization, and reliable customer support to make informed decisions that support your operational goals.

-

Custom Square Wire Mesh - High Quality, Wholesale Supply

NewsAug.15,2025

-

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

NewsAug.14,2025

-

Premium Rib Lath for Durable Stucco & Plaster Systems

NewsAug.13,2025

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025