-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 22, 2025 11:50 Back to list

Premium Hexagonal Wire Mesh | Galvanized & PVC Coated Solutions

Introduction to Hexagonal Wire Mesh Solutions

In industrial and civil engineering applications, the choice of robust and adaptable materials is paramount. hexagonal wire mesh stands out as a versatile and cost-effective solution, prized for its unique structural integrity and widespread utility. This product, often referred to as chicken wire mesh, is characterized by its distinctive hexagonal openings formed by twisting adjacent wires. Its inherent flexibility combined with high tensile strength makes it indispensable across diverse sectors, ranging from agricultural enclosures to complex civil engineering projects and erosion control systems. The primary variants, Galvanized Hexagonal Wire Mesh and PVC Coated Hexagonal Wire Mesh, offer distinct advantages, particularly in terms of corrosion resistance and longevity, making them suitable for environments demanding enhanced durability and protection.

This comprehensive overview is designed for B2B decision-makers and engineers seeking in-depth technical insights into hexagonal wire mesh. We will explore its intricate manufacturing processes, detailed technical specifications, diverse application scenarios, and the critical advantages it brings to various industries. Our discussion will also encompass customization options, vendor considerations, and real-world case studies, ensuring a holistic understanding of this fundamental material.

The Advanced Manufacturing Process of Hexagonal Wire Mesh

The production of high-quality hexagonal wire mesh is a sophisticated process involving precision engineering and stringent quality control. Understanding this process is crucial for appreciating the product's performance characteristics and ensuring its suitability for demanding applications.

Process Flow Overview:

- Material Selection: The foundation of durable hexagonal wire mesh lies in its raw material. Typically, low-carbon steel wire (Q195 or similar grades) is selected for its ductility and strength. For specialized applications, stainless steel (e.g., SS304, SS316) may be used for superior corrosion resistance. Wire diameter varies from 0.5mm to 4.0mm, depending on the required mesh strength and application.

- Wire Drawing: The selected raw wire coils undergo a drawing process to achieve the precise diameter required for the mesh. This step enhances the wire's tensile strength and improves surface finish.

- Galvanization (for Galvanized Hexagonal Wire Mesh): For hot-dip galvanized mesh, the drawn wires are cleaned thoroughly to remove impurities. They are then immersed in a bath of molten zinc. This process creates a metallurgically bonded zinc coating, offering excellent cathodic protection against rust and corrosion. Zinc coating thickness typically ranges from 40-300 g/m², conforming to standards such as ASTM A641 or EN 10244-2.

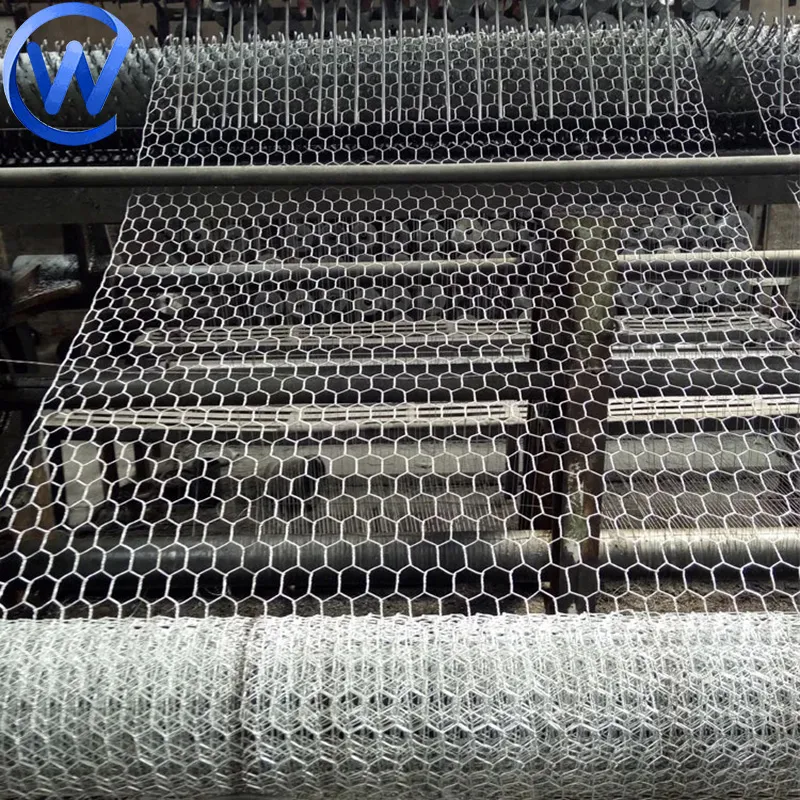

- Weaving Process: This is the core manufacturing step. Specialized mesh weaving machines twist the galvanized or plain wires together in a double or triple twist pattern to form hexagonal openings. This twisting mechanism ensures that even if one wire breaks, the mesh retains its integrity, preventing unraveling. The machine precisely controls the mesh opening size (e.g., 1/2 inch, 1 inch, 2 inches) and roll width.

- PVC Coating (for PVC Coated Hexagonal Wire Mesh): For PVC coated hexagonal wire mesh, the galvanized wire mesh rolls are then subjected to a powder coating or fluid bed dipping process where a layer of polyvinyl chloride (PVC) is applied. This additional coating provides superior protection against harsh chemicals, UV radiation, and extreme weather conditions, significantly extending the product's service life, especially in marine or acidic environments. The PVC thickness is typically around 0.3mm to 0.6mm.

- Trimming and Edging: After weaving and coating, the mesh rolls are trimmed to exact dimensions. The edges are often reinforced with a heavier gauge selvedge wire to prevent fraying and provide additional structural stability, facilitating easier installation and handling.

- Quality Control & Testing: Throughout the process, stringent quality checks are performed. This includes monitoring wire diameter, zinc coating weight, PVC coating thickness, mesh opening consistency, tensile strength, elongation, and adhesion tests (for PVC coating). Products are tested against international standards like ISO 9001 (for quality management), ASTM, and ANSI.

- Packaging: Finished hexagonal wire mesh rolls are securely packaged, often in waterproof paper or shrink-wrapped, to protect them during transit and storage.

Technical Specifications and Material Characteristics

The performance and suitability of hexagonal wire mesh for specific applications are dictated by its precise technical specifications and material properties. Understanding these parameters is critical for engineers and procurement specialists.

Key Parameters:

- Material: Low carbon steel wire (Q195/Q235), Stainless steel wire (SS304/SS316).

- Surface Treatment: Electro Galvanized, Hot-dip Galvanized (light/heavy zinc coating), PVC Coated.

- Wire Diameter (Gauge): Ranging from 0.5mm to 4.0mm (SWG 25 to 8).

- Mesh Opening Size: Common sizes include 3/8", 1/2", 5/8", 3/4", 1", 1 1/4", 1 1/2", 2", 3", 4" (9.5mm to 100mm).

- Roll Width: 0.5m to 2.0m (1.6 ft to 6.6 ft).

- Roll Length: Typically 30m, 50m, 100m (50 ft, 150 ft, 300 ft), custom lengths available.

- Tensile Strength: Typically 350-550 MPa for galvanized wire, ensuring structural integrity.

- Elongation: Minimum 10% for adequate flexibility without breakage.

- Service Life: Galvanized mesh: 10-20 years; PVC Coated mesh: 20-30+ years, depending on environmental conditions and coating quality.

Typical Product Specification Table:

| Feature | Galvanized Hexagonal Wire Mesh | PVC Coated Hexagonal Wire Mesh |

|---|---|---|

| Material | Low Carbon Steel (Q195) | Galvanized Low Carbon Steel Wire + PVC Coating |

| Surface Treatment | Hot-dip Galvanized (Heavy or Light Zinc) | Hot-dip Galvanized + PVC Powder/Dipped Coating |

| Wire Diameter (SWG) | 18 SWG (1.2mm) to 12 SWG (2.6mm) | 19 SWG (1.0mm) to 13 SWG (2.4mm) - core wire |

| Mesh Size (Opening) | 1/2", 3/4", 1", 2" (13mm, 19mm, 25mm, 50mm) | 1/2", 3/4", 1", 2" (13mm, 19mm, 25mm, 50mm) |

| Zinc Coating Weight | Min. 40 g/m² to Max. 300 g/m² | Min. 40 g/m² (under PVC) |

| PVC Coating Thickness | N/A | 0.3mm - 0.6mm per side |

| Roll Width | 0.5m - 2.0m | 0.5m - 2.0m |

| Roll Length | 30m, 50m, 100m | 30m, 50m, 100m |

| Typical Service Life | 10-20 Years | 20-30+ Years |

| Standards | ASTM A641, EN 10244-2 | ASTM F668, EN 10245-2 |

This table highlights the core distinctions between galvanized and PVC coated variants, primarily in their coating characteristics and expected longevity. The choice between them depends heavily on the environmental conditions and required lifespan of the application.

Industry Trends and Diverse Application Scenarios

The market for hexagonal wire mesh is experiencing dynamic growth, driven by increasing demands in infrastructure development, environmental protection, and agricultural sectors. Key trends include a rising preference for PVC coated variants due to their extended service life and aesthetic appeal, and a growing emphasis on custom hexagonal wire mesh solutions tailored for specific project requirements.

Target Industries and Applications:

- Agriculture & Poultry Farming: Widely known as chicken wire mesh, it's essential for constructing poultry fences, rabbit hutches, and general animal enclosures. Its flexibility allows for easy shaping around corners and irregular terrain. The robust nature of wholesale chicken wire mesh makes it a popular choice for large-scale operations.

- Construction & Infrastructure: Used as reinforcement in light concrete structures, plastering walls, and as insulation backing. Galvanized hexagonal wire mesh provides essential structural support.

- Erosion Control & Landscaping: Forming gabion baskets for river bank protection, retaining walls, and slope stabilization. The inherent flexibility allows it to conform to ground contours, while the galvanized or PVC coated wire ensures resistance to environmental degradation.

- Petrochemical & Mining: Used for protective screening, guards for machinery, and rockfall prevention in mining tunnels. The corrosion resistance of galvanized or PVC coated variants is critical in these harsh environments.

- Water Supply & Drainage: Employed in filtration systems, strainers, and channel lining to prevent debris ingress. The durability of PVC coated hexagonal wire mesh is particularly beneficial in constant moisture exposure.

- Gardening & Home Improvement: Creating garden fences, trellises, and protective barriers against pests. The availability of chicken wire mesh roll in various sizes caters to diverse needs.

Technical Advantages and Vendor Comparison

Technical Advantages:

- Superior Corrosion Resistance: Hot-dip galvanization provides a robust zinc layer (up to 300 g/m²) that sacrificially protects the steel, extending service life significantly. PVC coating offers an additional inert barrier, especially against acids, alkalis, and saline environments, making pvc coated hexagonal wire mesh ideal for coastal or industrial zones.

- High Flexibility and Formability: The double-twist weave allows the mesh to be easily cut, shaped, and installed over irregular surfaces without losing structural integrity. This is a critical advantage for gabion construction and terrain contouring.

- Enhanced Durability and Structural Stability: The hexagonal pattern distributes stress effectively, making the mesh highly resistant to impacts and localized damage. The twisted junctions prevent unraveling, even if individual wires are cut.

- Cost-Effectiveness: When considering initial investment versus long-term maintenance and replacement costs, both galvanized and PVC coated variants offer excellent value due to their extended lifespan and minimal upkeep requirements.

- Environmental Compatibility: Used extensively in erosion control and soil stabilization, hexagonal wire mesh supports natural vegetation growth within gabion structures, promoting ecological restoration.

Considerations for Vendor Comparison:

Selecting the right supplier for wholesale hexagonal wire mesh requires evaluating several key factors beyond just price. B2B buyers should focus on quality assurance, manufacturing capabilities, and comprehensive support services.

| Evaluation Criterion | Key Aspects to Assess | Impact on Project |

|---|---|---|

| Material Quality & Standards | Adherence to ASTM, ISO, EN standards for wire, galvanization, and PVC. Traceability of raw materials. | Ensures product longevity, structural integrity, and compliance with project specifications. Reduces failure risks. |

| Manufacturing Capabilities | Production capacity, lead times, ability to handle custom hexagonal wire mesh orders, consistency in weaving. | Reliable supply chain, timely project completion, availability of specialized products. |

| Quality Control & Testing | In-house testing facilities, certification (ISO 9001), detailed test reports, inspection protocols. | Guaranteed product performance, minimized defects, enhanced trust. |

| Customization Options | Flexibility in wire gauge, mesh opening, roll dimensions, and specific coating requirements. | Ability to meet unique project demands, optimized material usage, specialized solutions. |

| Logistics & Export Experience | Experience as hexagonal wire mesh exporters, efficient shipping, international certifications. | Smooth international transactions, timely delivery, reduced shipping complexities. |

| Technical Support & After-Sales | Availability of technical consultation, warranty, responsive customer service. | Assistance with product selection, installation guidance, problem resolution, long-term confidence. |

Customized Solutions and Application Case Studies

Tailored Hexagonal Wire Mesh for Specific Projects:

Recognizing that no two projects are identical, leading hexagonal wire mesh manufacturers offer extensive customization capabilities. This ensures that the product perfectly aligns with project specifications, environmental demands, and budgetary constraints. Customization options include:

- Specific Wire Gauges: From fine mesh for pest control to heavier gauges for gabion structures.

- Variable Mesh Openings: To control permeability or to meet precise aesthetic and functional requirements.

- Custom Roll Dimensions: Widths and lengths can be adjusted to minimize waste and streamline installation.

- Enhanced Coatings: Specialized galvanization weights or custom PVC colors (e.g., black, green, grey) for aesthetic integration or specific environmental protection.

- Material Alternatives: Stainless steel hexagonal wire mesh for applications requiring extreme corrosion resistance, such as marine environments or chemical processing plants.

Engaging with experienced hexagonal wire mesh exporters who prioritize custom solutions ensures optimal material performance and project efficiency.

Application Case Studies:

- Riverbank Stabilization in Southeast Asia: A major infrastructure project required robust erosion control for a river prone to seasonal flooding. Heavy-duty hot-dip galvanized hexagonal wire mesh (2.7mm wire, 80x100mm mesh) was used to construct large gabion baskets. These baskets were filled with local stones and strategically placed along the riverbanks. The flexibility of the mesh allowed it to conform to the riverbed's irregularities, while the heavy galvanization provided protection against prolonged water exposure. This solution effectively prevented soil erosion, protected nearby agricultural land, and supported the growth of riparian vegetation.

- Poultry Farm Expansion in Europe: A large-scale poultry operation needed cost-effective and durable enclosures for free-range chicken rearing. They opted for wholesale chicken wire mesh in PVC-coated green (1.0mm core wire, 25mm mesh). The PVC coating offered superior longevity against weather elements and manure exposure, while the green color blended seamlessly with the rural landscape. The flexibility of the chicken wire mesh roll enabled quick and efficient installation over varying terrains, significantly reducing labor costs and providing secure containment for livestock.

- Slope Protection in a Mountainous Region: To mitigate rockfall hazards along a newly constructed mountain road, a solution utilizing custom hexagonal wire mesh was implemented. Specialized steel wire (3.0mm, high tensile strength) with a double-twist weave and a heavy galvanized coating was used to create protective barriers and drapery systems. The mesh was anchored to the slope, allowing rocks to fall behind the mesh safely, or contained within the drapery, preventing them from reaching the roadway. This intervention significantly enhanced public safety and reduced maintenance requirements.

Ensuring Quality, Trustworthiness, and Support

Our commitment to delivering superior hexagonal wire mesh is built on a foundation of rigorous quality assurance, adherence to international standards, and unparalleled customer support. We understand that reliability and trust are paramount for B2B clients.

Quality & Authoritativeness:

- Certifications: Our manufacturing processes are ISO 9001:2015 certified, guaranteeing consistent quality management systems from raw material procurement to final product inspection. Products meet or exceed relevant ASTM and EN standards for wire mesh and coatings.

- Experience & Partnerships: With over two decades in the industry, we have cultivated partnerships with leading construction firms, agricultural enterprises, and governmental bodies globally. Our expertise as hexagonal wire mesh manufacturers and exporters is reflected in thousands of successful project deployments.

- Rigorous Testing: Every batch undergoes comprehensive testing, including tensile strength, zinc coating adhesion, PVC coating thickness, and mesh dimensional accuracy, using calibrated equipment. Test reports are available upon request.

Trustworthiness & Support:

Frequently Asked Questions (FAQ):

- Q: What is the primary difference between galvanized and PVC coated hexagonal wire mesh?

- A: Galvanized mesh offers excellent corrosion resistance through a zinc layer. PVC coated mesh provides an additional plastic layer over galvanized wire, offering superior protection against chemicals, UV radiation, and severe weather, significantly extending service life and allowing for color options.

- Q: Can your hexagonal wire mesh be customized for specific project needs?

- A: Absolutely. We offer extensive customization for wire gauge, mesh opening, roll dimensions, coating types, and colors to precisely match your project's technical specifications and environmental requirements.

- Q: What is your typical lead time for large orders?

- A: Standard orders typically have a lead time of 2-4 weeks. For large volume or highly customized orders, lead times can range from 4-8 weeks, depending on complexity and current production schedules. We always strive to meet client deadlines and provide transparent communication regarding fulfillment details.

Lead Time & Fulfillment:

We maintain efficient production lines and robust logistics networks to ensure timely delivery. Our dedicated team manages all aspects from order processing to dispatch, providing real-time updates on your shipment status. We have significant experience as hexagonal wire mesh exporters, navigating international shipping regulations and customs efficiently.

Warranty & Customer Support:

All our hexagonal wire mesh products come with a comprehensive warranty against manufacturing defects. The specific warranty period varies depending on the product type (e.g., 5-year for standard galvanized, up to 15-year for heavy PVC coated in specific conditions). Our expert technical support team is available to assist with product selection, installation guidance, and any post-purchase inquiries, ensuring your complete satisfaction.

References

- ASTM International. "ASTM A641/A641M - 03(2018) Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire."

- International Organization for Standardization. "ISO 9001:2015 Quality management systems – Requirements."

- European Committee for Standardization. "EN 10244-2: Steel wire and wire products - Non-ferrous metallic coatings on steel wire - Part 2: Zinc or zinc alloy coatings."

- National Academies of Sciences, Engineering, and Medicine. "Erosion and Sediment Control Technology."

-

Durable Fence Barbed Wire Solutions for Global Security & Agriculture

NewsNov.24,2025

-

Comprehensive Guide to Barbed Fence Wire – Durability, Uses & Innovations

NewsNov.23,2025

-

Barb Wire Price Per Roll – Understanding Costs, Trends & Global Applications

NewsNov.22,2025

-

Stainless Steel Barbed Wire: Durable Security for Global Industries & Relief Efforts

NewsNov.22,2025

-

Comprehensive Guide to Razor Wire Prices: Factors, Trends & Vendors

NewsNov.21,2025

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025