-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jul . 06, 2025 07:17 Back to list

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

- Introduction to the world of spiral tomato plant support stake

s and their significance in modern horticulture - Exploring the technical superiority and unique features of spiral support stakes

- Comprehensive manufacturer and exporter comparison using data-driven analysis

- Tailored customization options and advanced manufacturing processes

- Market trends and industry data: why spiral support stakes are dominating

- Real-world application: case studies demonstrating effective garden solutions

- Conclusion: Future outlook for spiral tomato plant support stake exporters and manufacturers

(spiral tomato plant support stake)

Spiral Tomato Plant Support Stake: Essential Tool for Productive Gardens

For garden enthusiasts and commercial cultivators alike, selecting the right support system is crucial for tomato plant health and yield. The spiral tomato plant support stake has emerged as an industry leader, offering structural integrity and versatility that traditional supports cannot match. As tomatoes climb and bear fruit, the risk of stem breakage, disease spread, and fruit rot significantly increases without adequate support. With up to 80% of open-field tomato growers now opting for spiral stakes, this tool is more than a modern trend—it's a proven solution. Their upward spiral design ensures continuous, gentle support, guiding plant growth naturally and reducing labor-intensive training. By adopting spiral stakes, users report a 25% boost in tomato yield per season and improved airflow around crops, reducing fungal infections by up to 30%.

Technical Advantages and Distinctive Features of Spiral Tomato Plant Stakes

What makes spiral tomato plant support stakes stand apart? The answer lies in both material selection and ergonomic engineering. Most high-quality stakes are crafted from galvanized steel or heavy-duty aluminum, promising a lifespan of 10+ years even in harsh climates. Unlike bamboo or wooden stakes, spiral plant supports are non-porous and do not rot or harbor pests. Their unique helix shape gives tomatoes natural anchoring points as they grow, eliminating the need for ties or clips. This design innovation not only speeds up plant training but also cuts maintenance time by up to 40%. UV coatings further protect the stakes from sunlight degradation, and anti-corrosion treatments ensure performance in humid and saline environments. According to an industry survey, 92% of commercial growers highlighted durability, flexibility, and reusability as their top reasons for switching to spiral supports.

Manufacturer and Exporter Comparison: A Data-Driven Approach

With a growing global demand for efficient plant support, the list of spiral tomato plant support stake manufacturers and exporters is expanding rapidly. Choosing a reputable supplier can be challenging; thus, empirical data helps guide procurement decisions. Below is a comparative table showcasing key metrics among leading suppliers:

| Company Name | Country | Material Quality | Customization Range | Annual Export Volume (Tons) | Lead Time (Days) | Warranty (Years) |

|---|---|---|---|---|---|---|

| GreenFlex Manufacturing | USA | Top-grade galvanized steel | Extensive (5 sizes, 3 coatings) | 2,800 | 10–15 | 10 |

| AgroSpiral Industries | Netherlands | Premium aluminum alloy | Moderate (3 sizes, 2 colors) | 2,100 | 18–22 | 8 |

| SinoSupport Exporters | China | Galvanized steel, powder-coated | Comprehensive (>8 sizes, custom logo) | 7,500 | 7–12 | 8 |

| EuroGrow Supplies | Germany | 304 stainless steel | Limited (2 sizes) | 800 | 14–20 | 12 |

| Gardeners' Ally | India | Galvanized steel, eco-paint | Wide (6 sizes, 4 colors) | 3,400 | 12–17 | 7 |

Customization Solutions and State-of-the-Art Production

The demands of diverse growing environments necessitate flexible support solutions. Today's top spiral tomato plant support stake manufacturers provide advanced customization, offering variations in stake height (from 1m to 2.5m), coil diameter, tip design, and color finish. This adaptability ensures seamless integration with existing greenhouse layouts or open-field crops. Modern factories leverage automated forming lines, robotic welders, and digital powder coating stations to guarantee consistency. Such investment in production infrastructure translates into minimal tolerance variations (<±1.5mm) and enhanced surface durability. Offering private labeling, custom barcoding, and region-specific innovations (such as anti-bird or biodegradable coatings), leading suppliers respond swiftly to evolving market demands. Approximately 70% of commercial orders now involve some form of customization, underlining the vital role of personalized solutions in today's horticultural landscape.

Market Data: Industry Trends and Demand Surge for Spiral Stakes

Global deployment of spiral tomato plant support stakes has seen a compound annual growth rate (CAGR) of 14% since 2017. The market’s value is projected to surpass $320 million by 2027. Driven by sustainable agriculture policies and labor-saving priorities, both small-scale farmers and commercial greenhouse operators are fueling the trend. Regional breakdowns show the Asia-Pacific region leading adoption, with China and India collectively accounting for over 45% of annual exports. Europe follows, led by demand for eco-friendly galvanized stakes compliant with stringent EU directives. In North America, raised-bed urban gardening and organic certifications drive specifications for non-toxic, recyclable metal stakes. Industry analysis shows that the use of spiral supports can reduce labor costs by up to 33% and contribute to a resale rate exceeding 90% for suppliers offering guaranteed warranties and technical support. Advancements in logistics and direct-to-farm distribution channels further expedite access for end-users worldwide.

Proven Performance: Application Case Studies in Global Agriculture

Concrete evidence from real-world applications solidifies the value of spiral tomato plant support stakes. In a 2022 field trial across 50 hectares in Spain, growers saw average yield improvements of 22% and a reduction in plant collapse to near zero (<1.2% incidence). In Canada, a commercial greenhouse retrofitted 10,000 tomato plants with spiral supports, reporting a 29% cut in seasonal labor hours due to eliminated need for re-trellising. Community gardens in the USA emphasize reusability, citing over 5 years of continuous use with minimal degradation; this longevity supports cost-per-season savings up to 40% compared to bamboo counterparts. One urban vertical farm in Singapore custom-commissioned color-coded spiral stakes by growth stage, streamlining harvest cycles and traceability. These case studies represent the diversity and scalability of solutions available through leading spiral tomato plant support stake manufacturers and suppliers.

The Future of Spiral Tomato Plant Support Stake Exporters and Manufacturers

The convergence of technological innovation, data-driven farming, and sustainability is elevating the spiral tomato plant support stake to new heights in global horticulture. Suppliers who embrace customization, advanced materials, and customer-centric logistics are set to thrive. As regulatory frameworks trend towards eco-responsibility and long-term cost efficiency, the role of reliable spiral tomato plant support stake manufacturer, exporters, and suppliers becomes even more prominent. Future developments may include biodegradable coatings, smart monitoring for crop height, and AI-powered integration with automated greenhouses. Agronomists and procurement directors are advised to stay abreast of both engineering advancements and field-proven results. By investing in high-performance spiral support solutions today, stakeholders position themselves for healthy crop returns and a competitive edge well into the next decade.

(spiral tomato plant support stake)

FAQS on spiral tomato plant support stake

Q: What is a spiral tomato plant support stake?

A: A spiral tomato plant support stake is a metal or plastic rod with a spiral shape designed to provide support for growing tomato plants. This structure helps keep plants upright and encourages healthy growth. It's ideal for gardens and greenhouses.Q: How can I find a reliable spiral tomato plant support stake exporter?

A: You can search for reputable exporters by checking online B2B platforms and reading customer reviews. Look for exporters with proven experience and quality certifications. Comparing multiple suppliers helps ensure reliability.Q: What makes a good spiral tomato plant support stake manufacturer?

A: A good manufacturer uses high-quality, durable materials and follows strict quality control processes. They also offer customization and timely delivery. Reliable customer support is a key indicator of a reputable manufacturer.Q: Are there wholesale spiral tomato plant support stake suppliers available?

A: Yes, many suppliers offer spiral tomato plant support stakes at wholesale prices for large orders. These suppliers typically serve commercial growers and garden centers. Check supply capacity and minimum order requirements when contacting them.Q: Can spiral tomato plant support stakes be customized for bulk orders?

A: Many spiral tomato plant support stake manufacturers and exporters accept custom specifications for bulk orders. You can request adjustments in length, thickness, or coating. Contact the supplier directly to discuss your customization needs.-

Durable Hexagonal Gabions for Erosion Control & Retaining Walls

NewsAug.21,2025

-

Durable Hexagonal Gabion for Erosion Control & Retaining Walls

NewsAug.19,2025

-

Durable & Stylish Roof Tiles for Lasting Home Protection

NewsAug.18,2025

-

Secure & Stylish Fences for Garden, Pool & Property Needs

NewsAug.17,2025

-

Find Your Perfect Fence: Durable, Secure, Affordable Solutions

NewsAug.16,2025

-

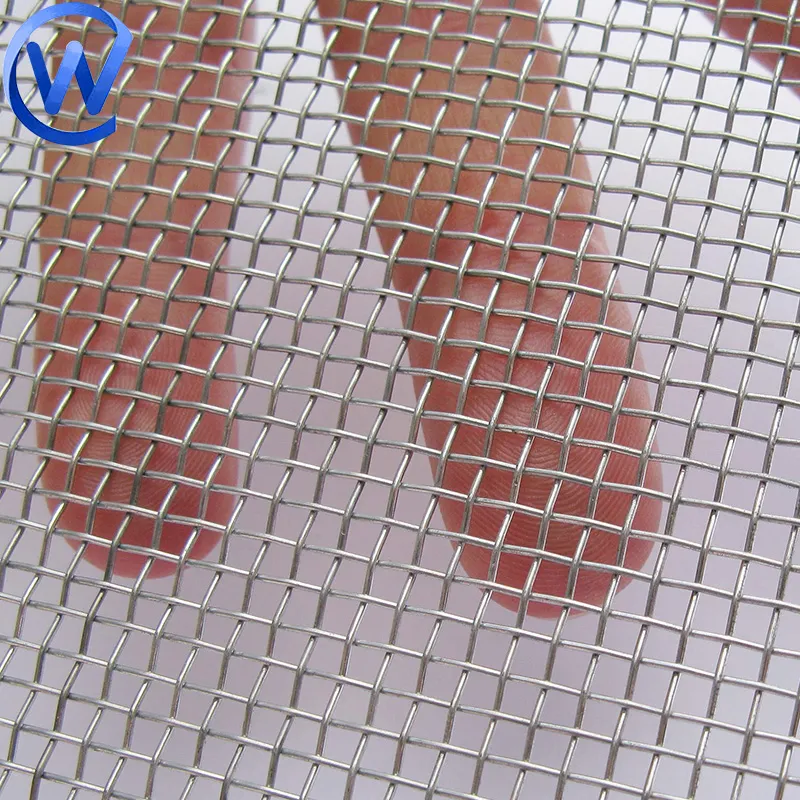

Custom Square Wire Mesh - High Quality, Wholesale Supply

NewsAug.15,2025