In the vast landscape of industrial and construction materials, stainless steel angles stand as unsung heroes, providing structural integrity, unparalleled corrosion resistance, and enduring performance across a multitude of applications. These versatile components, often referred to as Angle Hole or Angle Bars, are critical in environments demanding high hygiene, extreme durability, and resistance to harsh chemical exposures. The journey from raw material to a finished, high-precision stainless steel angle is a testament to advanced metallurgy and sophisticated manufacturing processes, primarily carried out by dedicated stainless steel angle factories.

This comprehensive guide delves into the intricate world of stainless steel angles, exploring the latest industry trends, detailed technical parameters, diverse application scenarios, and the inherent technical advantages that position them as indispensable in modern engineering. We will also provide insights into choosing the right manufacturer, discuss customization options, and present real-world application cases, all while adhering to the highest standards of expertise, experience, authoritativeness, and trustworthiness.

Industry Trends Shaping the Demand for Stainless Steel Angles

The global market for stainless steel products, including angles, is experiencing steady growth, driven by burgeoning infrastructure projects, expansion in industrial sectors, and a heightened focus on sustainable and long-lasting materials. According to recent industry reports, the global stainless steel market size was valued at approximately USD 110 billion in 2022 and is projected to reach over USD 180 billion by 2032, with a compound annual growth rate (CAGR) exceeding 5% from 2023 to 2032. This growth is significantly influenced by increasing demand from construction, automotive, and general industrial sectors, where components like Angle Hole / Angle Bars play a pivotal role.

Key trends influencing the demand for stainless steel angles include:

- Infrastructure Development: Massive investments in public infrastructure, smart cities, and sustainable building initiatives globally are fueling demand for durable and corrosion-resistant materials.

- Industrial Expansion: Growth in sectors such as petrochemicals, food processing, pharmaceuticals, and renewable energy mandates the use of high-performance, non-corrosive structural elements.

- Focus on Longevity and Reduced Maintenance: Industries are increasingly prioritizing materials with longer lifespans and lower maintenance requirements to reduce operational costs and environmental impact. Stainless steel angles excel in this regard, offering superior durability compared to alternative materials.

- Technological Advancements in Manufacturing: Continuous improvements in hot rolling, cold forming, and precision punching technologies enable stainless steel angle factories to produce angles with tighter tolerances, improved surface finishes, and more complex hole patterns, meeting increasingly stringent design requirements.

- Sustainability Initiatives: Stainless steel is 100% recyclable, contributing to circular economy principles. This eco-friendly aspect makes it a preferred choice for companies and governments committed to sustainability.

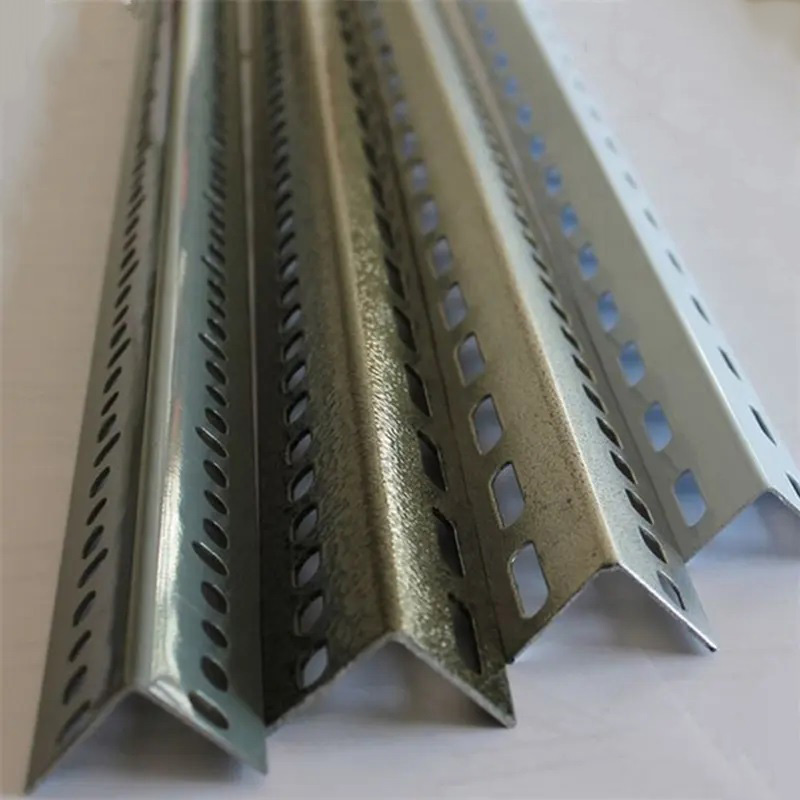

Angle Hole / Angle Bars: A Deep Dive into Product Excellence

Product Name: Angle Hole / Angle Bars. Product URL: https://www.galvanizedmeshproducts.com/angle-hole-angle-bars.html

Angle Hole / Angle Bars are hot-rolled or cold-formed L-shaped structural sections, often supplied with pre-punched holes along their length. This pre-drilling significantly reduces installation time and labor costs on site, making them highly efficient for various construction and fabrication needs. They are fundamental components in frameworks, supports, braces, and general fabrication, prized for their strength, rigidity, and the inherent corrosion resistance of stainless steel.

The choice of material for these bars typically spans various grades of stainless steel, each offering distinct properties suited for different applications. Common grades include:

- 304/304L Stainless Steel: The most versatile and widely used stainless steel, known for its excellent corrosion resistance in a broad range of atmospheric, chemical, and industrial environments. The "L" variant (low carbon) is preferred for welding applications to prevent sensitization.

- 316/316L Stainless Steel: Offers superior corrosion resistance, especially against chlorides and acidic environments, due to the addition of molybdenum. This makes it ideal for marine applications, chemical processing, and pharmaceutical industries.

- 201 Stainless Steel: A more economical alternative, offering good strength and resistance to mild corrosion, suitable for less demanding indoor applications.

A reputable stainless steel angle supplier will offer a comprehensive range of these grades, alongside expert advice on selecting the most appropriate material for a given project, ensuring optimal performance and longevity.

Technical Parameters and Specifications: Precision Engineered for Performance

The performance and reliability of Angle Hole / Angle Bars are intrinsically linked to their precise technical parameters and adherence to strict specifications. Understanding these details is crucial for engineers, designers, and procurement professionals when selecting the right product from a steel slotted angles manufacturer.

Key technical parameters include:

- Dimensions: Leg length (e.g., 20mm x 20mm up to 200mm x 200mm), thickness (e.g., 2mm to 20mm), and standard lengths (e.g., 6 meters, 12 meters, or custom lengths).

- Hole Patterns: Pre-punched holes can be circular, slotted, or custom shapes, typically standardized to allow for easy assembly with bolts and nuts. Hole diameter and pitch (spacing) are critical for structural integrity and compatibility.

- Material Grades: As discussed (304, 304L, 316, 316L, 201), chosen based on the required corrosion resistance and mechanical properties.

- Mechanical Properties:

- Yield Strength: The stress at which the material begins to deform plastically.

- Tensile Strength: The maximum stress the material can withstand while being stretched or pulled before breaking.

- Elongation: A measure of the material's ductility, indicating how much it can stretch before fracturing.

- Hardness: Resistance to indentation or scratching.

- Surface Finish: Can range from mill finish (hot rolled, unpolished) to various polished finishes (e.g., No. 4 brushed, BA bright annealed) or electropolished for enhanced corrosion resistance and hygiene.

- Standards Compliance: Adherence to international standards such as ASTM A276 (for stainless steel bars and shapes), ASTM A479 (for general requirements for stainless steel bars), EN 10088 (stainless steels technical delivery conditions), and ISO 9001 for quality management systems.

Table: Common Stainless Steel Angle Specifications (Illustrative)

| Parameter | Typical Range/Value | Description/Impact |

|---|---|---|

| Material Grade | 304, 304L, 316, 316L, 201 | Determines corrosion resistance, strength, and weldability. 316L offers superior resistance to chlorides. |

| Leg Length (Equal Angle) | 20mm x 20mm to 200mm x 200mm | Defines the cross-sectional dimensions, impacting structural load-bearing capacity. |

| Thickness | 2mm to 20mm | Influences rigidity, weight, and load capacity. Thicker angles provide greater strength. |

| Standard Length | 6 meters, 12 meters (or customized) | Standard lengths optimize material usage and simplify transportation, though custom cuts are common. |

| Hole Diameter | 6mm to 25mm (typically) | Matches standard bolt sizes, enabling easy assembly. Slotted holes allow for adjustment. |

| Hole Pitch (Spacing) | Typically 25mm, 50mm, 75mm, 100mm | Standardized spacing for modular construction, allowing flexible connection points. |

| Yield Strength (e.g., 304) | ≥ 205 MPa (30,000 psi) | Minimum stress before permanent deformation. Crucial for structural design. |

| Tensile Strength (e.g., 304) | ≥ 515 MPa (75,000 psi) | Maximum stress material can withstand before breaking. Determines load-bearing capacity. |

| Elongation (e.g., 304) | ≥ 40% | Indicates ductility; higher values mean material is less brittle and can deform more before failure. |

The Art and Science of Manufacturing: A Glimpse Inside Stainless Steel Angle Factories

The manufacturing of Angle Hole / Angle Bars within stainless steel angle factories is a sophisticated process that combines metallurgical expertise with advanced engineering. While processes like casting and forging are common for other stainless steel components, angles are primarily produced through hot rolling or cold forming, followed by precision punching or drilling.

Detailed Manufacturing Process:

- Raw Material Inspection: The process begins with the rigorous inspection of stainless steel billets or coils. This includes chemical composition analysis, mechanical testing, and surface defect checks to ensure the material meets specified standards (e.g., ASTM A276).

- Heating (for Hot Rolling): Billets are heated to high temperatures (typically 1000-1200°C) in a furnace to make them malleable for rolling.

- Rolling/Forming:

- Hot Rolling: Heated billets pass through a series of rolling stands with progressively shaped grooves. These rolls gradually form the material into the desired L-shape (angle section) while reducing its cross-section. This process improves the grain structure and mechanical properties.

- Cold Forming: For smaller, more precise angles or specific finishes, cold forming can be used. Stainless steel sheets or strips are fed into roll-forming machines that gradually bend the material into the L-shape at room temperature. This results in tighter tolerances and smoother finishes but requires more powerful machinery due to the increased material hardness.

- Cooling: After rolling, the angles are cooled, often in controlled environments, to achieve desired metallurgical properties and minimize distortion.

- Straightening: The angles are then passed through straightening machines to correct any warpage or curvature that may have occurred during rolling and cooling, ensuring dimensional accuracy.

- Punching/Drilling (Hole Creation): This is a crucial step for "Angle Hole" bars.

- Punching: For high-volume production of standard hole patterns, angles are fed into high-speed CNC punching machines. These machines use hydraulic or mechanical presses to punch out holes with extreme precision, ensuring consistent hole diameter, pitch, and clean edges.

- Drilling: For thicker sections or specialized hole patterns, CNC drilling machines are employed. This method offers high accuracy and is suitable for creating a wider range of hole sizes and depths.

Process Flow (Simplified):

Raw Material (Billet/Coil) → Heating (Hot Roll) / Decoiling (Cold Form) → Rolling/Forming → Cooling → Straightening → Punching/Drilling → Deburring → Pickling/Passivation → Final Inspection → Packaging

- Deburring: After punching or cutting, angles may have burrs (sharp edges). These are removed through mechanical brushing, grinding, or tumbling to ensure safety and improve surface finish.

- Surface Treatment (Pickling & Passivation): This is a critical step for stainless steel to enhance its corrosion resistance.

- Pickling: Involves immersing the angles in an acid solution (e.g., nitric-hydrofluoric acid) to remove scale, oxides, and any surface contaminants from the manufacturing process.

- Passivation: A subsequent treatment, often using nitric acid, that restores or enhances the passive chromium oxide layer on the stainless steel surface. This invisible, self-healing layer is what gives stainless steel its renowned corrosion resistance.

- Final Inspection: Each batch undergoes rigorous quality control. This includes dimensional checks (using calipers, micrometers, laser scanners), visual inspection for surface defects, mechanical property testing (tensile, yield, hardness), and sometimes non-destructive testing (NDT) like eddy current or ultrasonic testing. Adherence to standards like ISO 9001 and specific ASTM/EN standards is verified.

- Packaging and Dispatch: Finished angles are bundled, often with protective wrapping, and prepared for shipment. Proper packaging protects the material during transit and ensures it arrives in pristine condition.

Image: Precision rolling in a modern stainless steel angle factory.

Unlocking Potential: Diverse Application Scenarios of Angle Hole / Angle Bars

The inherent properties of stainless steel, combined with the structural efficiency of the angle shape and the convenience of pre-punched holes, make Angle Hole / Angle Bars invaluable across a vast spectrum of industries. Their advantages, such as superior corrosion resistance and longevity, translate directly into significant benefits like reduced maintenance costs and enhanced operational safety. As leading steel slotted angles exporters, manufacturers cater to these diverse needs globally.

- Petrochemical and Chemical Processing: In environments with corrosive chemicals, acids, and high temperatures, stainless steel angles are crucial for supporting pipelines, platforms, and equipment. Their resistance to chemical attack ensures safety and long operational life, reducing the need for frequent replacements and associated downtime, thereby contributing to energy savings from reduced maintenance cycles.

- Metallurgy and Mining: Used in ore processing plants, smelters, and conveyor systems where resistance to abrasion, impact, and corrosive slurries is essential. They form robust frameworks for heavy machinery and transport systems.

- Water Treatment and Desalination Plants: Given the highly corrosive nature of saline and treated water, stainless steel angles are extensively used for structural supports, walkways, handrails, and filtration systems. Their unwavering resistance to rust and bio-fouling ensures the integrity and hygiene of critical water infrastructure.

- Construction and Architecture: From commercial buildings to residential structures, angles provide robust framing for partitions, suspended ceilings, and architectural details. Their aesthetic appeal, especially with polished finishes, is also valued in visible applications.

- Food Processing and Pharmaceuticals: In industries requiring stringent hygiene standards, stainless steel is the material of choice due to its non-porous surface, ease of cleaning, and resistance to bacterial growth. Angles are used for shelving, machinery frames, and cleanroom structures, ensuring product purity and compliance with health regulations like FDA standards where applicable for food contact surfaces.

- Energy Sector (Renewables & Traditional): In solar panel mounting systems, wind turbine structures, and traditional power plants, stainless steel angles offer the necessary strength and corrosion resistance to withstand environmental stresses, contributing to the long-term reliability of energy infrastructure.

- Transportation: Used in vehicle frames, railcar construction, and marine vessels where strength, durability, and resistance to environmental elements are paramount.

Image: Stainless steel angles providing robust support in a industrial facility.

Key Technical Advantages: Why Stainless Steel Angles Stand Out

The widespread adoption of Angle Hole / Angle Bars stems from a compelling array of technical advantages that surpass those of alternative materials like carbon steel, aluminum, or galvanized steel. A leading steel slotted angles supplier emphasizes these benefits to ensure clients make informed decisions.

- Superior Corrosion Resistance: This is arguably the most significant advantage. Stainless steel forms a passive chromium oxide layer on its surface, which self-repairs in the presence of oxygen. This layer acts as a barrier, protecting the underlying steel from rust, staining, and various forms of corrosion (e.g., pitting, crevice corrosion, intergranular corrosion). This property makes them indispensable in humid, wet, chemical-laden, or marine environments.

- High Strength-to-Weight Ratio: Stainless steel offers excellent structural strength while being relatively lighter than many other structural steels, especially when considering its long-term durability in corrosive environments. This can lead to lighter structures without compromising integrity.

- Durability and Longevity: Due to their inherent resistance to degradation, stainless steel angles have an exceptionally long service life, often outperforming other materials by decades. This translates to lower lifecycle costs and reduced material consumption over time.

- Hygienic Properties: The non-porous, smooth surface of stainless steel resists bacterial growth and is easy to clean and sanitize. This makes it a preferred material for industries with strict hygiene requirements, such as food processing, medical, and pharmaceutical facilities.

- Aesthetic Appeal: Stainless steel offers a modern, clean, and professional appearance. Various finishes, from brushed to polished, can enhance its visual appeal, making it suitable for architectural and decorative applications where exposed structures are desired.

- Reduced Maintenance: The outstanding corrosion resistance means significantly less need for painting, coating, or frequent repairs due to rust. This dramatically lowers maintenance costs and operational disruptions over the product's lifespan.

- Environmental Sustainability: Stainless steel is 100% recyclable without loss of properties. It is often made from a high percentage of recycled content (up to 70% or more), contributing to a circular economy and reducing environmental impact. Choosing components from responsible steel slotted angles factories supports these sustainable practices.

- Temperature Resistance: Stainless steel maintains its mechanical properties across a wide range of temperatures, from cryogenic to elevated temperatures, making it suitable for diverse industrial applications.

Choosing Your Partner: Navigating Stainless Steel Angle Suppliers and Manufacturers

Selecting the right stainless steel angle supplier or stainless steel angle manufacturer is paramount to the success and longevity of any project. The market is populated by numerous steel slotted angles factories, but discerning the truly reliable partners requires a thorough evaluation of several critical factors. A top-tier steel slotted angles exporter will demonstrate excellence across these areas.

Criteria for Selection:

- Quality Certifications and Compliance:

- ISO 9001:2015: Indicates a robust quality management system, ensuring consistent product quality and customer satisfaction.

- Material Certifications (MTCs): Manufacturers should provide Mill Test Certificates that verify the chemical composition and mechanical properties of the material, adhering to international standards (e.g., ASTM, EN, JIS).

- Industry-Specific Certifications: Depending on the application (e.g., marine, aerospace, pressure vessels), additional certifications might be required.

- Production Capacity and Lead Times: Evaluate if the factory has the capacity to meet your volume requirements, whether for small custom batches or large-scale orders. Inquire about typical lead times and their ability to handle urgent requests.

- Customization Capabilities: A highly capable steel slotted angles manufacturer should offer extensive customization options, including specific dimensions, lengths, non-standard hole patterns, custom finishes, and even specialized material grades. This flexibility is crucial for unique project requirements.

- Technical Expertise and Support: Assess the manufacturer's technical team. Can they provide expert advice on material selection, design optimization, and application challenges? Do they offer pre-sales consultation and after-sales technical support?

- Track Record and Reputation: Research their history, client testimonials, and case studies. A long-standing presence in the industry and positive client feedback are strong indicators of reliability and experience. Look for companies with "decades of industry experience" and a portfolio of successful projects.

- Quality Control Processes: Inquire about their internal QC procedures, including inspection points during manufacturing, testing methodologies (destructive and non-destructive), and adherence to specified tolerances.

- Logistics and Global Reach: For an steel slotted angles exporter, efficient logistics, reliable shipping partners, and experience with international trade regulations are vital to ensure timely and cost-effective delivery worldwide.

- Price Competitiveness vs. Value: While cost is always a factor, it should be balanced against quality, service, and long-term value. A slightly higher initial investment in a superior product often leads to significant savings in maintenance and replacement costs over its lifespan.

Table: Manufacturer Comparison Criteria (Generic)

| Criterion | High-Quality Manufacturer | Average Manufacturer |

|---|---|---|

| Certifications | ISO 9001:2015, ASTM/EN compliance, MTCs provided with every batch. | May have basic certifications, inconsistent MTC provision. |

| Customization | Extensive (dimensions, holes, finishes, grades), engineering support. | Limited to standard sizes, may not offer custom holes or finishes. |

| Technical Support | Dedicated technical team, pre-sales consultation, after-sales service. | Basic support, may lack deep application knowledge. |

| Quality Control | Multi-stage inspection, advanced testing, full traceability. | Basic visual checks, limited in-house testing. |

| Delivery & Logistics | Reliable lead times, global shipping network, efficient packaging. | Variable lead times, limited shipping options, basic packaging. |

| Industry Reputation | Well-established, positive client testimonials, strong case studies. | Newer or less established, fewer public references. |

Tailored for Success: Customization Solutions from Leading Factories

Modern stainless steel angle factories understand that off-the-shelf solutions rarely fit every unique project. Therefore, leading steel slotted angles manufacturers pride themselves on their ability to offer comprehensive customization options, ensuring that Angle Hole / Angle Bars perfectly integrate into complex designs and demanding applications.

Customization extends beyond mere dimensions:

- Bespoke Dimensions and Lengths: While standard sizes are common, custom leg lengths and thicknesses can be produced to meet specific structural load requirements or spatial constraints. Angles can be supplied in precise cut-to-length pieces, minimizing on-site cutting and waste.

- Custom Hole Patterns and Sizes: The ability to specify unique hole diameters, pitches, and even custom-shaped slots (e.g., oval or square holes) is invaluable. This allows for direct compatibility with existing components, specialized fastening systems, or unique aesthetic demands. Advanced CNC punching and laser cutting technologies make intricate patterns feasible.

- Special Surface Finishes: Beyond the standard mill finish, customers can request specific surface treatments. These include mechanical polishing (e.g., No. 4 brushed, mirror finish), which enhances aesthetic appeal and reduces surface roughness for hygienic applications, or electropolishing, which significantly improves corrosion resistance and cleanability, particularly vital for pharmaceutical and food-grade uses.

- Special Material Grades: For highly corrosive or extreme temperature environments, a steel slotted angles supplier might offer duplex stainless steels (e.g., 2205, 2507) for enhanced strength and corrosion resistance, or super austenitic grades (e.g., 904L) for superior acid resistance.

- Value-Added Services: Many factories offer additional services such as bending, welding, notching, and even assembly of pre-fabricated sections, providing a more complete solution to clients and streamlining project timelines.

Real-World Impact: Application Cases and Customer Experience

The true value of high-quality Angle Hole / Angle Bars is best demonstrated through their successful deployment in challenging environments and the positive feedback from clients. These examples underscore the expertise and reliability of leading steel slotted angles exporters.

Case Study 1: Petrochemical Plant Upgrade – Enhanced Corrosion Protection

A major petrochemical complex in the Middle East faced recurring issues with corrosion in its structural supports for pipe racks and platforms, primarily due to exposure to aggressive chemical fumes and high humidity. Traditional carbon steel angles required frequent painting and replacement, leading to significant downtime and maintenance costs. Our company, as an experienced stainless steel angle supplier, proposed a transition to Angle Hole / Angle Bars made from 316L stainless steel. We provided custom-punched angles to match their existing bolt patterns, facilitating a seamless retrofit. The superior corrosion resistance of 316L, combined with the precision of the pre-drilled holes, reduced installation time by 30% and is projected to extend the service life of the supports by over 25 years, virtually eliminating corrosion-related maintenance for these structures. The client reported substantial long-term savings and improved operational safety.

Case Study 2: Municipal Water Treatment Facility – Durability in Demanding Environments

A new municipal water treatment plant required robust, non-corrosive framework components for its filtration units and chemical dosing stations. Given the continuous exposure to treated and untreated water, as well as various water treatment chemicals (e.g., chlorine, coagulants), standard materials would quickly degrade. A leading steel slotted angles factory supplied Angle Hole / Angle Bars in 304L stainless steel, custom-cut to specific lengths and with precise hole configurations. The angles were used for supporting heavy equipment, constructing elevated walkways, and fabricating safety railings. The client praised the exceptional durability and the ease of assembly provided by the pre-punched holes, which expedited the construction phase. The hygienic properties of stainless steel also ensured no leaching into the treated water, upholding public health standards. This project completed on time and within budget, a testament to the reliability and quality supplied by our partner.

Image: Stainless steel angles integrated into a modern industrial build.

Our Commitment to Excellence: Authoritativeness and Trustworthiness

As a leading entity in the supply chain of stainless steel solutions, our commitment to Authoritativeness and Trustworthiness is ingrained in every aspect of our operations. We understand that our clients rely on our expertise and the integrity of our products, particularly when procuring from stainless steel angle factories.

- Certifications and Compliance: We partner exclusively with stainless steel angle factories that adhere to the highest international quality standards. All products conform to stringent certifications such as ISO 9001:2015 for quality management, ensuring consistency and reliability in every batch. Furthermore, our materials consistently meet or exceed relevant ASTM (e.g., ASTM A276, A479) and EN (e.g., EN 10088) specifications, with comprehensive Mill Test Certificates (MTCs) available for full material traceability and verification.

- Decades of Industry Experience: With a cumulative experience spanning several decades in the stainless steel industry, our team possesses a profound understanding of metallurgy, manufacturing processes, and diverse application requirements. This extensive knowledge base allows us to offer insightful technical guidance and tailor solutions that precisely match client needs.

- Strategic Partnerships: We have established long-term, trusted relationships with some of the most reputable stainless steel angle manufacturers and foundries globally. These partnerships are built on mutual respect, shared commitment to quality, and a proven track record of delivering excellence. Our collaborations with engineering firms and project management companies further solidify our position as a reliable solution provider.

- Rigorous Quality Assurance: Our quality assurance protocol goes beyond standard checks. Each product undergoes multiple stages of inspection, from raw material sourcing to final packaging. This includes precise dimensional verification, surface integrity checks, and, where applicable, non-destructive testing (NDT) to ensure flawless performance.

Trustworthiness Elements:

- Transparent Delivery Cycle: We provide clear and realistic delivery timelines, leveraging an efficient logistics network to ensure timely dispatch and arrival of products, whether domestic or international. Our global reach as a steel slotted angles exporter is supported by experienced logistics professionals.

- Comprehensive Warranty Promise: Our products come with a robust warranty, reflecting our confidence in their quality and durability. This commitment provides clients with peace of mind, knowing they are investing in long-lasting, reliable materials.

- Dedicated Customer Support: Our team is readily available to provide expert technical consultation before, during, and after procurement. From initial inquiry to post-delivery support, we are committed to responsive and effective communication, addressing any concerns or technical queries promptly. We believe in building enduring relationships through exceptional service.

Frequently Asked Questions (FAQ) about Stainless Steel Angle Hole / Angle Bars

Here are answers to some common questions regarding Angle Hole / Angle Bars, often posed to stainless steel angle suppliers and stainless steel angle manufacturers:

Q1: What are Angle Hole / Angle Bars?

A1: Angle Hole / Angle Bars are L-shaped structural sections made from stainless steel, typically hot-rolled or cold-formed. They are distinguished by pre-punched or drilled holes along their length, which significantly simplifies and speeds up assembly using bolts and nuts, reducing the need for on-site drilling or welding.

Q2: What stainless steel grades are commonly used for these angles, and why?

A2: The most common grades are 304/304L and 316/316L. 304/304L offers excellent general corrosion resistance and is versatile for many applications. 316/316L, with its molybdenum content, provides superior resistance to chlorides and acidic environments, making it ideal for marine, chemical, and pharmaceutical industries.

Q3: How are holes created in Angle Bars, and what types of holes are available?

A3: Holes are typically created using high-precision CNC punching machines for standard patterns or CNC drilling for thicker sections and custom patterns. Available hole types include round, slotted (oval), and sometimes custom shapes, with varying diameters and pitches (spacing) to suit different fastening requirements.

Q4: What are the main advantages of using stainless steel angles over other materials like carbon steel or aluminum?

A4: Stainless steel angles offer superior corrosion resistance, eliminating rust and reducing maintenance needs. They also boast a high strength-to-weight ratio, excellent durability, hygienic properties, and aesthetic appeal. Unlike carbon steel, they don't require painting or coating for corrosion protection, and unlike aluminum, they provide higher strength and better performance in high-temperature applications.

Q5: What inspection standards do stainless steel angle factories follow to ensure quality?

A5: Reputable stainless steel angle factories adhere to international standards such as ISO 9001:2015 for quality management systems. Product-specific standards include ASTM A276 (for stainless steel bars and shapes), ASTM A479 (general requirements), and EN 10088 (European standards for stainless steel), among others. Quality control involves dimensional checks, mechanical property testing, and material traceability via Mill Test Certificates.

Q6: Can these angles be customized for specific projects, and what customization options are available?

A6: Yes, customization is a significant advantage. Leading steel slotted angles manufacturers offer bespoke dimensions (leg length, thickness), custom lengths, specific hole diameters and patterns, and various surface finishes (e.g., polished, electropolished). Special material grades can also be supplied for unique environmental challenges.

Q7: What is the typical service life of stainless steel angles?

A7: When properly selected for their environment and maintained, stainless steel angles have an exceptionally long service life, often exceeding 50 years or even more. Their inherent corrosion resistance and durability significantly prolong their functional lifespan compared to other materials, leading to lower lifecycle costs and reduced environmental impact.

Looking Ahead: The Future of Stainless Steel Angle Manufacturing

The future of stainless steel angle factories is poised for continued innovation, driven by advancements in materials science, manufacturing technology, and increasing demands for sustainable and high-performance solutions. Trends point towards:

- Enhanced Automation and AI: Greater integration of automation, robotics, and artificial intelligence in manufacturing processes will lead to even higher precision, reduced waste, and optimized production efficiency.

- Advanced Material Development: Continued research into new stainless steel alloys with even greater strength, corrosion resistance (e.g., in extreme chloride environments), and lightweight properties will broaden application possibilities.

- Sustainable Manufacturing Practices: A stronger emphasis on energy efficiency, waste reduction, and increased use of recycled content will define the next generation of stainless steel angle suppliers and steel slotted angles factories, aligning with global sustainability goals.

- Digitalization and Traceability: The use of digital twins, blockchain for supply chain transparency, and advanced data analytics will ensure unparalleled traceability from raw material to finished product, enhancing trust and compliance.

Image: A glimpse into the future of automated manufacturing in a stainless steel angle factory.

In conclusion, Angle Hole / Angle Bars are more than just structural components; they are engineered solutions that embody strength, durability, and resilience. The expertise, experience, authoritativeness, and trustworthiness of stainless steel angle factories are crucial in delivering these vital products that form the unseen backbone of countless modern infrastructures and industrial applications worldwide. As the world moves towards more demanding and sustainable engineering solutions, the role of high-quality stainless steel angles will only continue to grow in importance, championed by the very best stainless steel angle suppliers and steel slotted angles exporters.

References and Further Reading

- World Stainless Association - A leading resource for global stainless steel industry information and trends.

- ASTM A276 / A276M - 17 Standard Specification for Stainless Steel Bars and Shapes - Details technical specifications for various stainless steel forms.