-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 09, 2024 12:46 Back to list

Leading Manufacturer of Durable Stainless Steel Grating for Various Applications

The Rise of Stainless Steel Grating Manufacturers

In recent years, the demand for stainless steel grating has seen a significant increase across various industries. As a result, the number of stainless steel grating manufacturers has also surged, contributing to new innovations and improvements in the quality and functionality of these products. This article delves into the importance of stainless steel grating, the manufacturing process, and key considerations when choosing a manufacturer.

What is Stainless Steel Grating?

Stainless steel grating is a versatile material made from stainless steel bars arranged in a grid pattern. It is commonly used in industrial flooring, walkways, platforms, and stair treads. The primary reasons for the popularity of stainless steel grating include its durability, corrosion resistance, and aesthetic appeal. Unlike traditional steel grating, which may rust and deteriorate over time, stainless steel grating retains its integrity and appearance, making it ideal for environments with exposure to moisture, chemicals, and other corrosive elements.

The Manufacturing Process

The process of manufacturing stainless steel grating involves several key steps

1. Material Selection Manufacturers typically choose high-quality stainless steel, often in grades 304 or 316, depending on the application. Grade 316, for example, is particularly resistant to corrosion in marine environments.

2. Cutting and Shaping The stainless steel is cut into bars and then shaped into the required dimensions. Precision cutting is essential to ensure that the grating fits the intended application perfectly.

3. Welding The bars are welded together at predetermined intervals to form a grid pattern. Advanced welding techniques are applied to ensure strong and reliable bonds between the bars, enhancing the overall structural integrity of the grating.

4. Finishing After welding, the grating undergoes finishing processes such as grinding and polishing. This step not only improves the aesthetic look of the grating but also removes any sharp edges that could pose safety risks.

stainless steel grating manufacturer

5. Quality Control Reputable manufacturers implement rigorous quality control checks throughout the production process. This includes testing for strength, durability, and corrosion resistance to ensure that the final product meets industry standards.

Choosing the Right Manufacturer

When selecting a stainless steel grating manufacturer, several factors should be considered to ensure that you receive a high-quality product that meets your specific needs

1. Experience and Reputation Look for manufacturers with a proven track record in the industry. Established companies are more likely to adhere to high manufacturing standards and provide reliable products.

2. Customization Options Depending on your project requirements, you may need grating in specific sizes, patterns, or finishes. A flexible manufacturer that offers customization options can better meet your unique needs.

3. Certifications and Compliance Ensure that the manufacturer adheres to industry regulations and has the necessary certifications. This not only guarantees product quality but also instills confidence in the integrity of the materials used.

4. Customer Support A responsive customer support team can assist you throughout the purchasing process. From inquiries about product specifications to post-purchase support, good customer service can enhance your overall experience.

5. Cost While price should not be the sole determining factor, it is essential to consider your budget. Obtaining quotes from multiple manufacturers can help you find a balance between quality and cost.

Conclusion

The stainless steel grating market is growing rapidly as industries recognize the benefits of this durable and aesthetically pleasing material. With the rise of stainless steel grating manufacturers, consumers have more options than ever. By understanding the manufacturing process and key factors to consider when choosing a manufacturer, businesses can make informed decisions that enhance safety, efficiency, and longevity in their applications. Whether for industrial use or architectural purposes, stainless steel grating continues to be a popular choice for those seeking quality and reliability.

-

Find Your Perfect Fence: Durable, Secure, Affordable Solutions

NewsAug.16,2025

-

Custom Square Wire Mesh - High Quality, Wholesale Supply

NewsAug.15,2025

-

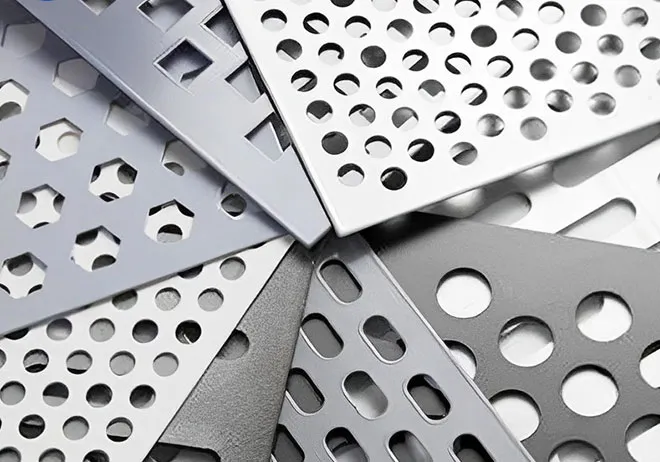

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

NewsAug.14,2025

-

Premium Rib Lath for Durable Stucco & Plaster Systems

NewsAug.13,2025

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025