-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 03, 2024 10:33 Back to list

steel fence panel factory

The Rise of Steel Fence Panel Factories A Comprehensive Overview

In recent years, the demand for durable and aesthetically pleasing fencing solutions has surged, making the steel fence panel factory an increasingly crucial player in the construction and landscaping industry. These factories specialize in producing high-quality steel fence panels that offer superior security, longevity, and low maintenance compared to traditional wooden or vinyl fencing options.

The Advantages of Steel Fencing

Steel fencing provides numerous benefits, contributing to its growing popularity among homeowners, businesses, and industrial applications. One of the most significant advantages is durability. Steel panels can withstand harsh weather conditions, including high winds, heavy rains, and snow. Unlike wood, which can warp, rot, or be infested by termites, steel panels maintain their integrity over time, resulting in a longer lifespan and reduced replacement costs.

Another key benefit is security. Steel fence panels create a formidable barrier against unauthorized entry, making them an ideal choice for commercial properties, schools, and private residences. The strength of steel provides peace of mind, knowing that the risk of physical breaches is minimized. Additionally, many manufacturers offer customization options, allowing customers to choose heights, finishes, and additional security features, such as barbed wire or electrified options.

Manufacturing Process

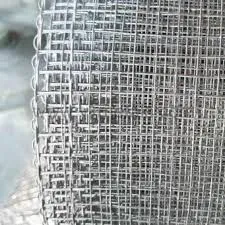

The manufacturing process of steel fence panels involves several critical steps, ensuring that the final product meets the highest quality standards. It begins with sourcing high-grade steel, which is then cut and shaped into the desired panel specifications. Factories employ advanced techniques such as welding and galvanization to enhance the strength and corrosion resistance of the panels.

steel fence panel factory

Welding fuses the steel components together, providing a robust structure that can endure physical stress. After welding, the panels undergo galvanization, where a protective zinc coating is applied to prevent rust and deterioration. This process is vital for ensuring that the fences can withstand exposure to moisture and varying temperatures, making them suitable for a range of climates.

Environmentally Friendly Practices

As awareness of environmental issues rises, many steel fence panel factories are adopting sustainable practices. Recycled steel is increasingly used in production, significantly reducing the environmental impact associated with new steel production. Additionally, steel is fully recyclable at the end of its life, making it a more eco-friendly choice compared to wood, which requires deforestation and does not contribute back to nature after its usage.

Moreover, modern steel fence manufacture often incorporates energy-efficient machinery and sustainable practices throughout the production process, further enhancing the environmental benefits of steel fencing solutions.

Conclusion

The growth of steel fence panel factories signifies a shift toward more sustainable, durable, and secure fencing options in both residential and commercial markets. With continuous advancements in manufacturing technology and a focus on environmental stewardship, steel fencing stands out as an increasingly viable alternative to conventional fencing materials. As consumers’ preferences evolve, it's clear that steel fence panels will play a vital role in the future of fencing solutions, offering a perfect blend of strength, security, and aesthetic appeal. The industry's commitment to quality and sustainability promises a bright future for steel fencing, making it an indispensable part of modern construction and landscaping projects.

-

Durable Fence Barbed Wire Solutions for Global Security & Agriculture

NewsNov.24,2025

-

Comprehensive Guide to Barbed Fence Wire – Durability, Uses & Innovations

NewsNov.23,2025

-

Barb Wire Price Per Roll – Understanding Costs, Trends & Global Applications

NewsNov.22,2025

-

Stainless Steel Barbed Wire: Durable Security for Global Industries & Relief Efforts

NewsNov.22,2025

-

Comprehensive Guide to Razor Wire Prices: Factors, Trends & Vendors

NewsNov.21,2025

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025