-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 10, 2025 11:40 Back to list

Looking for Security Window Screen Mesh That Protects?

Security Window Screen Mesh: the quiet upgrade that hardens your home without changing how it feels

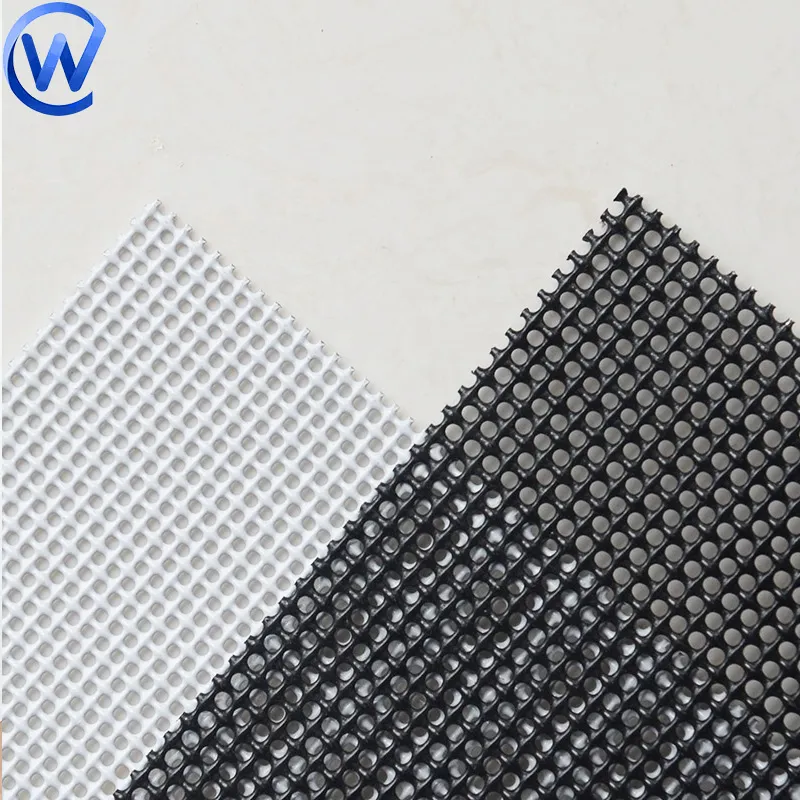

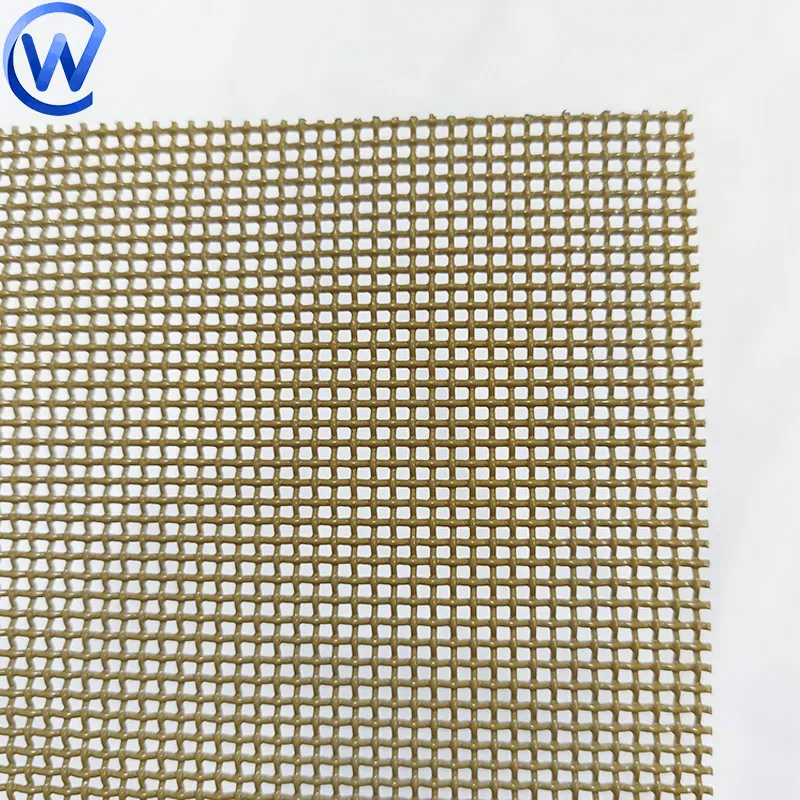

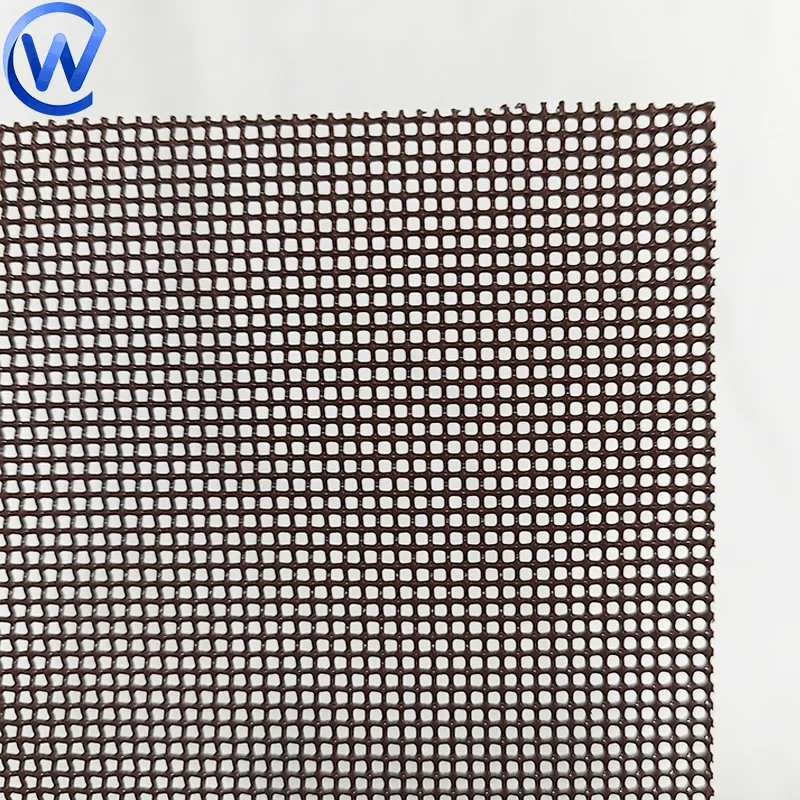

I’ve walked a lot of job sites this year and, to be honest, the biggest shift I’m seeing is the move to stainless security screens that look like regular fly screens but behave like a barrier. The Security Window Screen Mesh from Anping’s South Industrial Zone 07, Hebei, China, is a good example—stainless (201/202/304/316/316L), electrostatic powder-coated, and tough enough to shrug off prying tools, flying debris, and in certain builds, even serious impact. Many customers say they forget it’s there after a week.

Why the market is moving this way

Urban densification, coastal builds, and insurance pressure—those three trends are nudging specifiers toward stainless 304/316 screens. Add tighter standards (impact, knife-shear, and corrosion testing) and it’s no surprise that black powder-coated 316L is becoming the default for premium homes and schools. Actually, installers love that it fits into standard window suites with minimal fuss.

Key specifications (typical)

| Item | Typical Value (≈) | Notes |

|---|---|---|

| Material grades | 201 / 202 / 304 / 316 / 316L | 304 indoor/general; 316/316L coastal |

| Wire diameter | ≈ 0.8–1.0 mm | Cold-drawn SS wire per ASTM A580 |

| Mesh count | 10×10 or 11×11 | Open area ≈ 40–50%, good airflow |

| Coating | Electrostatic powder, 60–80 μm | UV-stable, matte black/gray most common |

| Impact/knife tests | Pass 100 J impact; knife shear ≥ 350 N | When built to AS 5039/5040 systems |

| Corrosion resistance | ISO 9227 salt-spray > 1,000 h (316L) | Real-world use may vary |

Process flow and QA (quick tour)

Materials arrive as certified SS wire (A580). Then: precision weaving → degrease/rinse → phosphate or chromate-free pretreat → electrostatic powder spray → oven cure → flatness tensioning → frame fit-up → test. Typical checks: wire tensile, coating thickness, cross-hatch adhesion, 100 J dynamic impact, knife-shear, and ISO 9227 salt spray. Expected service life: around 10–20 years depending on grade and coastal exposure.

Where it’s used (and why)

- Homes and villas: daytime ventilation with nighttime peace of mind.

- Coastal apartments: 316L handles salt; fewer call-backs, in my experience.

- Schools/healthcare: anti-tamper, easy cleaning, no bars-on-windows look.

- Retail/data rooms: discreet barrier against prying and smash attempts.

Advantages people actually notice: clear outward visibility, strong anti-corrosion performance, and a surprisingly quiet slam-resistance when paired with proper frames. One facilities manager told me, “we ventilate more and rely less on AC.”

Vendor snapshot (indicative)

| Vendor | Core Grade | Coating | Tests/Certs | Warranty | Lead Time | Price |

|---|---|---|---|---|---|---|

| Anping Manufacturer (Origin: South Industrial Zone 07) | 304 / 316 / 316L | Polyester TGIC powder | AS 5039 tests; ISO 9227 | Up to 10 yrs | ≈ 12–18 days | $$ |

| Premium AU Brand | 316 marine | Architectural powder | AS 5039 certified | 10–15 yrs | ≈ 5–7 days | $$$$ |

| Generic OEM | 201/202 | Basic powder | Limited | 1–3 yrs | ≈ 20–30 days | $ |

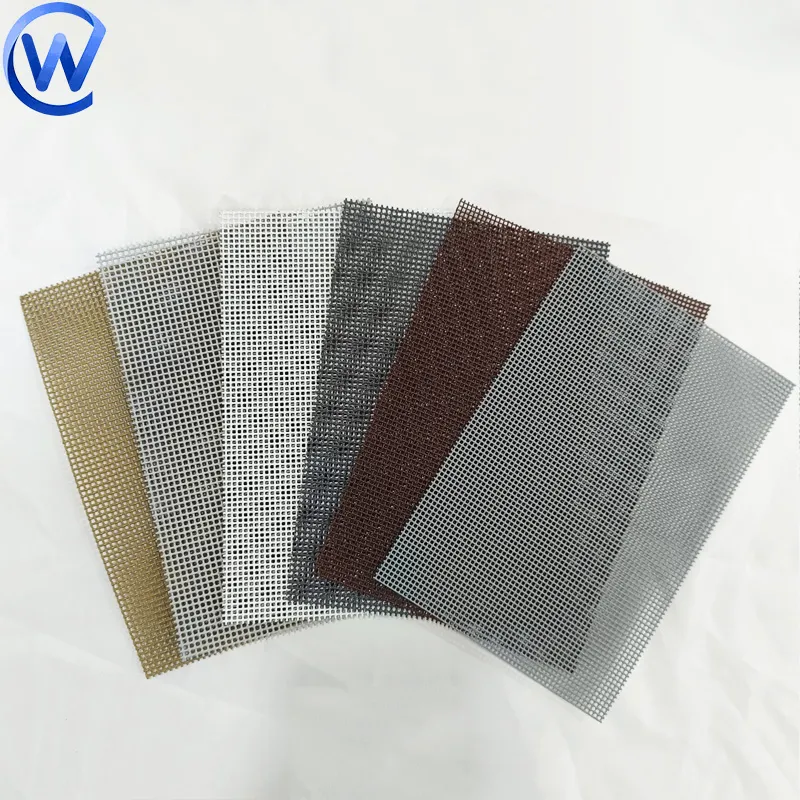

Customization options

- Grades: 304 for inland; 316/316L for marine; 201/202 for budget.

- Mesh: 10×10 / 11×11; wire 0.8–1.0 mm; panel up to ≈ 1500×3000 mm.

- Colors: RAL blacks/charcoals, low-sheen preferred by architects.

- Frames/hardware: compatible with most hinged/slider suites; child-safe latches.

- Packing & cut-to-size programs for installers; OEM labeling available.

Real-world notes

Case 1—Coastal villa: 316L screens passed 1,000 h salt-spray equivalence; after 18 months seaside, zero blistering reported. Case 2—Primary school retrofit: replaced bars with Security Window Screen Mesh; teachers said airflow improved and the classrooms felt “less institutional.” Bullet resistance claims depend on the total system (mesh, frame, fasteners, glazing); confirm against UL 752 levels if that’s in scope.

Ready to spec? Ask for the latest test reports (AS 5039/5040, ISO 9227) and pick 316L if you smell salt in the air.

Authoritative references

- ASTM A580/A580M – Standard Specification for Stainless Steel Wire.

- ISO 9227:2017 – Corrosion tests in artificial atmospheres — Salt spray tests.

- AS 5039 & AS 5040 – Security screen doors and window grilles; Installation.

- UL 752 – Standard for Bullet-Resisting Equipment (system-level evaluation).

-

Durable Fence Barbed Wire Solutions for Global Security & Agriculture

NewsNov.24,2025

-

Comprehensive Guide to Barbed Fence Wire – Durability, Uses & Innovations

NewsNov.23,2025

-

Barb Wire Price Per Roll – Understanding Costs, Trends & Global Applications

NewsNov.22,2025

-

Stainless Steel Barbed Wire: Durable Security for Global Industries & Relief Efforts

NewsNov.22,2025

-

Comprehensive Guide to Razor Wire Prices: Factors, Trends & Vendors

NewsNov.21,2025

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025