-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 13, 2025 12:25 Back to list

Roof Tiles - Durable, Weatherproof, Lightweight & Stylish

Lighting Roof Tiles: Field Notes from Real Jobsites

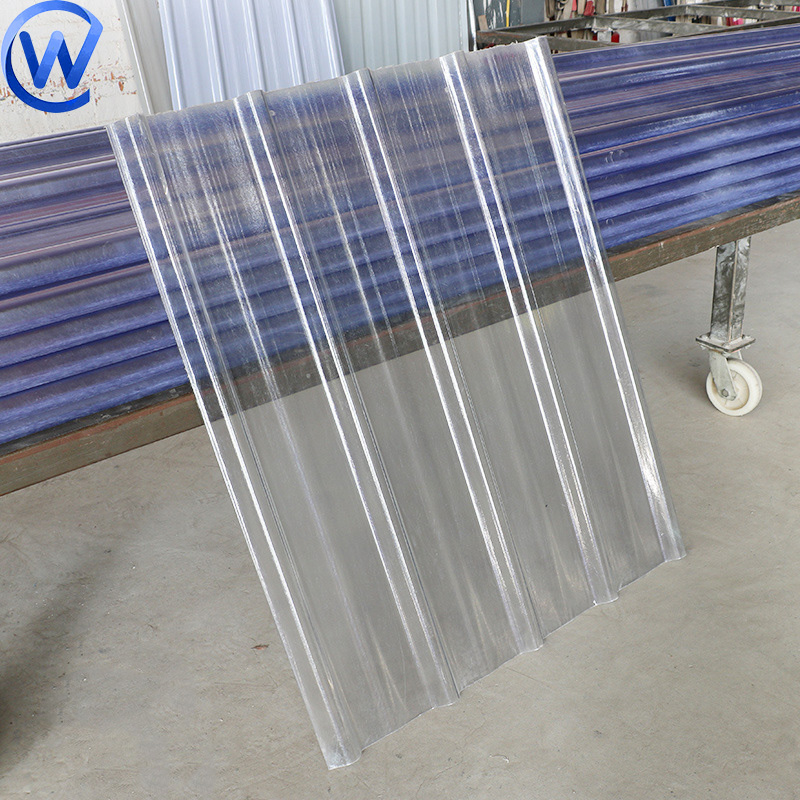

If you’re weighing daylighting on a tight energy budget, start with Roof Tiles from the source in South Industrial Zone 07, Anping County, Hebei, China. I’ve toured the plant—lots of resin drums, glass rovings, and that reassuring smell of production, not a showroom. These tiles (also called transparent roof panels, light belts, skylight sheets—pick your dialect) come in FRP, PC, PET, and UPVC. And yes, each behaves a bit differently in the wild.

Trends I’m Seeing

More owners want soft daylight, fewer roof penetrations, and lower HVAC bills. FRP still rules in corrosive or coastal air; PC sheets are winning when architects chase optics (≈85% transmittance and tidy aesthetics). UPVC/PET step in for budget-conscious retrofits. Frankly, the “payback” pitch lands when maintenance teams stop replacing brittle panels every two winters.

Specification Snapshot (real-world values may vary)

| Type | Thickness (mm) | Light Transmittance | Temp Range | Notes/Standards |

|---|---|---|---|---|

| FRP (fiberglass) | 1.0–3.0 | ≈60–80% | -40 to +120°C | ASTM D3841, ISO 4892-2; strong anti-corrosion |

| PC (polycarbonate) | 0.8–2.0 | ≈82–85% | -40 to +120°C | ASTM D1003 haze, UL 94 options; impact-tough |

| PET | 0.8–1.5 | ≈78–84% | -20 to +70°C | Cost-effective; fair UV, watch heat |

| UPVC | 1.2–2.5 | ≈65–75% | -10 to +60°C | Good chemical resistance; budget-friendly |

Typical service life: FRP 15–25 years (with UV film/gel coat), PC 10–20 years (co-extruded UV), PET/UPVC 8–15 years depending on sun load and maintenance. Fire behavior is application- and resin-dependent; ratings per ASTM E84 or EN 13501-1 available upon request.

How They’re Made (short version)

FRP: continuous lamination of polyester resin + glass mat/roving + UV absorbers, cured under heat with surface film (often PMMA/ASA) for weathering. PC: pellet drying, extrusion, co-extruded UV cap layer. QC includes light transmission (ASTM D1003), impact (Izod/Charpy), accelerated weathering (ISO 4892-2), and surface burning tests (ASTM E84) as required. I’ve watched operators reject panels for micro-bubbles—good sign.

Where They Shine

- Factories, warehouses, sports halls—long daylight bands reduce electric load.

- Livestock and agritech sheds—FRP stands up to ammonia and salt.

- Transit hubs, canopies, corridors—PC for clarity and impact resistance.

Vendor Reality Check

| Supplier | Certs/Reports | Customization | Lead Time | Notes |

|---|---|---|---|---|

| Anping Source Factory | ISO 9001; test data to ASTM D3841/E84, ISO 4892-2 | Profiles, color, UV cap, anti-drip | ≈10–20 days | Best on price-to-performance |

| Domestic Distributor | Basic COA, limited fire reports | Color/length mostly | Stock-based | Fast for small projects |

| Generic Importer | Varies; verify! | Limited | Uncertain | Check UV and warranty terms |

Customization and Options

Colors (clear, blue, opal), corrugation match to metal roof profiles, length to order (less splices = fewer leaks), anti-condensation film, anti-static coating, and fire-retardant resins for code-driven projects. Many customers say the anti-drip layer paid for itself in the first winter.

Quick Case Notes

- Coastal fishery warehouse: FRP bands, salt-laden air—zero yellowing at year 3; maintenance team “finally stopped replacing brittle panels.”

- Greenhouse retrofit: PC sheets ≈85% transmittance; growers reported more uniform early-morning light.

- Logistics hub: UPVC on budget; acceptable light, fast install; planned upgrade to FRP on expansion.

Final thought: choose Roof Tiles by environment first (chemicals, wind, sun load), then by optics and budget. And ask for the test reports—saves you grief later.

Authoritative Standards

- ASTM D3841 – Standard Specification for Glass-Fiber-Reinforced Polyester Plastic Panels. https://www.astm.org/d3841

- ASTM E84 – Standard Test Method for Surface Burning Characteristics of Building Materials. https://www.astm.org/e0084

- ISO 4892-2 – Plastics: Methods of exposure to laboratory light sources. https://www.iso.org/standard/68395.html

- EN 13501-1 – Fire classification of construction products and building elements. https://standards.cen.eu

-

Durable Fence Barbed Wire Solutions for Global Security & Agriculture

NewsNov.24,2025

-

Comprehensive Guide to Barbed Fence Wire – Durability, Uses & Innovations

NewsNov.23,2025

-

Barb Wire Price Per Roll – Understanding Costs, Trends & Global Applications

NewsNov.22,2025

-

Stainless Steel Barbed Wire: Durable Security for Global Industries & Relief Efforts

NewsNov.22,2025

-

Comprehensive Guide to Razor Wire Prices: Factors, Trends & Vendors

NewsNov.21,2025

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025