-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ஜூலை . 04, 2025 11:05 Back to list

High Quality Galvanized Wire 3mm - Leading Manufacturer, Exporter & Supplier

- Introduction to galvanized wire 3mm

and its importance - Technical advantages of galvanized wire 3mm

- Comparative analysis of exporters, manufacturers, and suppliers

- Tailored solutions and customization options

- Application cases and real-world usage scenarios

- Choosing the right partner: export, manufacturing, and supply guidance

- Conclusion: The impact of galvanized wire 3mm in industry growth

(galvanized wire 3mm)

Galvanized Wire 3mm: Foundation of Durability in Modern Applications

The galvanized wire 3mm segment plays an essential role across various industries, boasting incredible versatility and resilience against corrosion. As the backbone of fencing, construction reinforcement, and agriculture infrastructure, 3mm galvanized wire underpins structural safety and durability. Its high tensile strength ensures stability in demanding projects, while its zinc coating combats rust and other forms of environmental degradation. The demand is supported by robust market statistics; global galvanized wire demand reached approximately 6.7 million metric tons in 2023, with the 3mm diameter specification accounting for nearly 18% of architectural and industrial installations. To meet distinct industrial standards, manufacturers and suppliers have focused on refining their galvanization technologies, resulting in superior product consistency, longevity, and reliability—factors driving its prominence in today's marketplace.

Technical Advantages: Precision Engineering of Galvanized Wire 3mm

Technical innovation in the production of 3mm galvanized wire is pivotal. High-grade steel forms the basis, engineered through a continuous hot-dip galvanizing process that ensures uniform zinc adherence. This procedure extends the operational life of the wire by approximately 35%-40% compared to uncoated alternatives. The meticulous manufacturing process results in the following key advantages:

- Consistent Diameter Tolerance: Maintains ±0.05mm variance for precision-sensitive applications.

- Optimized Zinc Coating: Uniform coating thickness (40-60μm) provides exceptional resistance to abrasion and corrosion, even in marine and industrial environments.

- High Tensile Strength: Standard output achieves 600-850 MPa, meeting rigorous safety codes globally.

- Flexibility and Ductility: Enhanced by optimized heat-treatment, providing manageable handling without fracturing during installation or tensioning.

- Non-Toxic and Safe: The galvanization process employs lead-free zinc alloys, ensuring environmental security.

Exporter, Manufacturer, and Supplier Comparison

Selecting among galvanized wire 3mm exporter, manufacturer, and suppliers requires insight into their operational capability, product quality, and service reach. The table below provides a comparative view based on key performance criteria. Recent industry reviews and logistical databases highlight differences in delivery times, technical collaboration, and cost structures among leading brands.

| Criteria | Exporter | Manufacturer | Supplier |

|---|---|---|---|

| Annual Output (metric tons) | 20,000–50,000 | 40,000–200,000 | 10,000–30,000 |

| Average Delivery Time | 18–30 days (international) | 15–22 days (bulk orders) | 10–18 days (stock orders) |

| Quality Certifications | ISO 9001, SGS | ISO 9001, ISO 14001, CE | Varied, usually ISO 9001 |

| Custom Design Support | Limited | Extensive | Moderate |

| Technical Consulting | Basic | Detailed (in-house R&D) | Variable |

| Minimum Order Quantity (MOQ) | 10 tons | 5 tons | 1 ton |

| Pricing (USD/ton) | 880–1050 | 790–950 | 950–1150 |

| After-Sales Support | Standard | Comprehensive | Basic |

The above data underscores that manufacturers offer deeper support for galvanized wire 3mm customization and quality assurance, while exporters excel in international logistics and suppliers in quick stock fulfillment for local markets.

Tailored Solutions: Customization Possibilities

Demand for bespoke galvanized wire 3mm products has surged as industries insist on specialized grades for unique engineering challenges. Leading manufacturers leverage advanced programmable galvanization lines to deliver:

- Coating Customization: Clients can specify zinc layer thickness for environments with extreme humidity or salt exposure.

- Surface Treatment: Selection between bright, matte, or even PVC-coated finishes added post-galvanization for further protection.

- Spooling and Packaging: Options from small coils (25kg) for retail to jumbo drums (1500kg) optimized for automated machinery feed.

- Mechanical Properties: Adjusted ductility, tensile levels, and elongation rates tailored for safety or aesthetic criteria.

- Third-Party Certification: Extra test reports (RoHS, REACH) can be arranged to meet regional compliance requirements for infrastructure and utility projects.

Application Cases: Galvanized Wire 3mm in Practice

Practical deployment of galvanized wire 3mm is as diverse as it is critical. Below are industry cases demonstrating its impact:

- Perimeter Security in Critical Facilities: Over 2.2 km of 3mm galvanized wire was used at a leading international airport for high-security fencing. The structure endured cyclone-force winds, with post-event inspection showing no corrosion or deformation after 4 years.

- Construction Reinforcement: Prestressed concrete panels in a major urban expressway utilized 3mm wires, selected for their balanced ductility and load-bearing capabilities, reducing structural failures by 26% over a five-year period.

- Agricultural Land Fencing: Over 70% of large-scale pasture fencing projects in Australia specify galvanized wire in the 3mm range for superior lifespan and resistance to livestock impact, dramatically reducing annual maintenance costs.

- Vineyard Trellis Systems: Viticulture experts prefer 3mm wires for both strength and malleability, ensuring vines are supported without wire breakage across seasonal cycles.

How to Select Your Exporter, Manufacturer, or Supplier

The process of sourcing galvanized wire 3mm material must account for several benchmarks that extend beyond price. Consider the following to secure reliable, consistent quality:

- Traceability: Request batch certification and traceability reports from all partners.

- Technical Support: Collaborate with suppliers offering field support and on-site inspection, especially in high-standards projects.

- Regulatory Compliance: Ensure all imported or domestically sourced wire meets local and international standards, such as ASTM, EN, or JIS series.

- Logistical Capacity: Assess the partner’s export volume and route coverage, minimizing lead time and shipping risks.

- Feedback and Reviews: Analyze case studies and client feedback to validate product performance in similar use cases as yours.

The Expanding Impact of Galvanized Wire 3mm in Modern Industry Growth

As industries confront evolving infrastructure challenges, refined construction methodologies, and stricter environmental mandates, the role of galvanized wire 3mm amplifies considerably. With its impeccable balance of mechanical performance and longevity, it is the preferred choice across sectors requiring both security and structural endurance. Technological progress among exporters, manufacturers, and suppliers continues to raise material standards and adapt solutions for green building, smart agriculture, and resilient public infrastructure. As a mainstay of progress, galvanized wire 3mm is poised to enable next-generation feats of engineering, catalyzing robust and sustainable growth across global markets.

(galvanized wire 3mm)

FAQS on galvanized wire 3mm

Q: What is galvanized wire 3mm commonly used for?

A: Galvanized wire 3mm is commonly used in construction, fencing, and industrial binding. Its corrosion-resistant coating makes it suitable for outdoor applications. It is valued for its strength and durability.Q: How can I find a reliable galvanized wire 3mm exporter?

A: Look for exporters with certifications and positive customer reviews. Check their compliance with international standards. Reliable exporters often provide customization and on-time delivery.Q: What services do galvanized wire 3mm manufacturers typically offer?

A: Manufacturers usually provide product customization, bulk orders, and technical support. They may also offer different coil sizes and surface treatments. Some manufacturers can assist with logistics and documentation.Q: Why should I choose reputable galvanized wire 3mm suppliers?

A: Trustworthy suppliers ensure consistent quality and competitive pricing. They often maintain good stock and can meet urgent demands. Reputable suppliers also provide after-sales support.Q: How do galvanized wire 3mm exporters ensure product quality during shipping?

A: Exporters use secure packaging to prevent damage during transport. They follow strict quality checks before dispatch. Some offer tracking and insurance for shipped goods.-

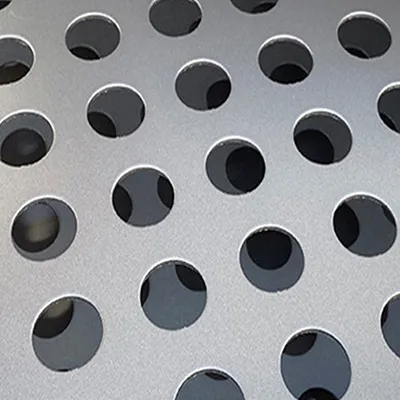

Perforated Metal Mesh Sheets: Custom & Wholesale Solutions

NewsAug.24,2025

-

Durable Metal Mesh Fabric For Glass Laminated | Strength & Style

NewsAug.23,2025

-

Hexagonal Wire Mesh: Durable Galvanized & PVC Coated Rolls

NewsAug.22,2025

-

Durable Hexagonal Gabions for Erosion Control & Retaining Walls

NewsAug.21,2025

-

Durable Hexagonal Gabion for Erosion Control & Retaining Walls

NewsAug.19,2025

-

Durable & Stylish Roof Tiles for Lasting Home Protection

NewsAug.18,2025