-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 14, 2025 09:35 Back to list

Hexagonal Gabion – Durable Double‑Twisted, Galvanized/PVC

Field Notes on the Hexagonal Gabion: where civil practicality meets tough engineering

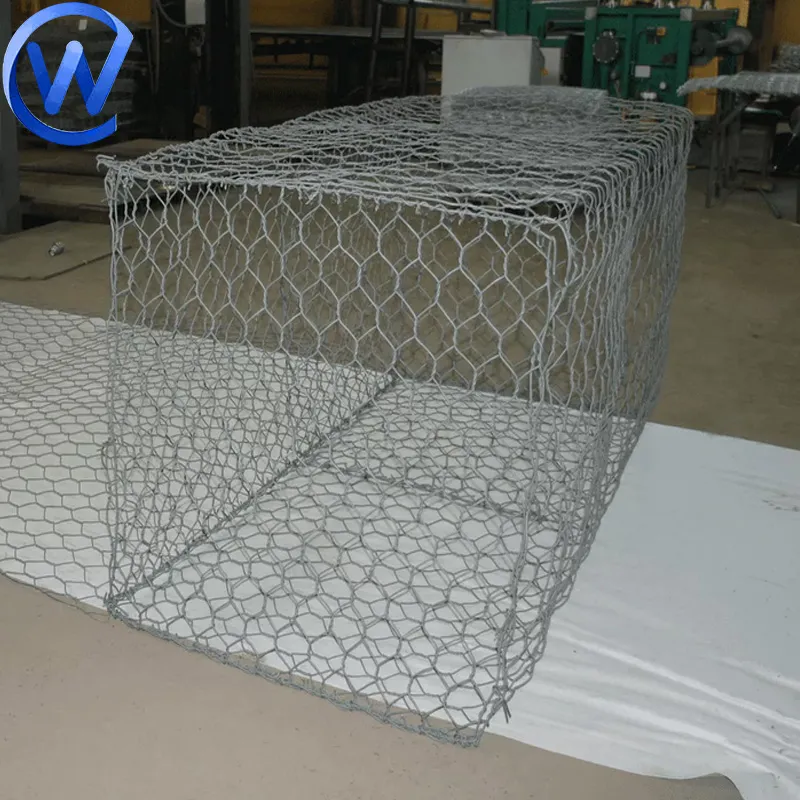

If you’ve spent time on riverbanks or under highways (professionally, I mean), you’ve seen gabions doing quiet, unsung work. The Hexagonal Gabion—double-twisted mesh, rock-filled—has become the industry’s go-to for slope stabilization, scour control, and those gnarly corners where soil, water, and time fight for dominance. Origin matters too: this model comes out of South Industrial Zone 07, Anping County, Hebei, China—an area that practically breathes wire mesh.

What’s trending (and why engineers care)

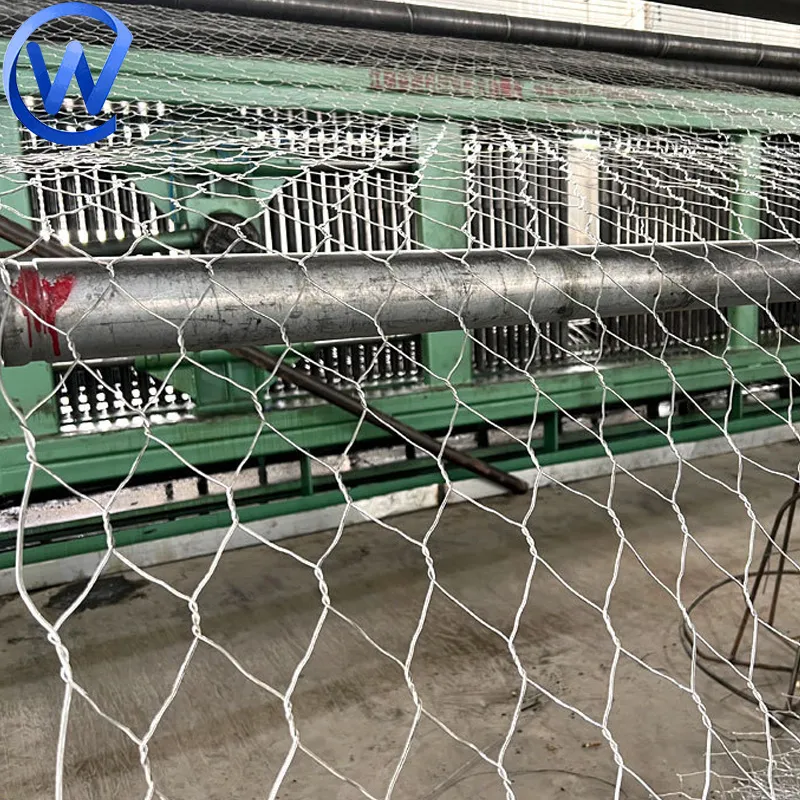

Two big shifts: heavier zinc coatings and smarter polymer overcoats. Designers are specifying ASTM A975 or EN 10223-3 compliant double-twist mesh more consistently, with zinc ≥ 230 g/m² and PVC/PE after-galvanizing for aggressive waters. In fact, several agencies now lean toward Type 3 (polymer-coated) for coastal and de-icing salt environments. Many customers say the upfront premium pays back in reduced inspections and fewer emergency repairs. Hard to argue.

Process flow and QA snapshot

- Materials: hot-dipped galvanized low-carbon steel wire; optional heavy-galv Zn or Zn-Al (Galfan); PVC/PE coating.

- Methods: double-twist hexagonal weaving; diaphragms at ≈1 m spacing; selvedge wire heavier than mesh wire.

- Testing: coating mass per EN 10244-2; tensile 350–550 MPa typical; salt-spray ISO 9227/ASTM B117 (lab runs up to 3,000 h, no red rust on polymer-coated areas, internal data).

- Service life: ≈ 30–50 years galvanized; ≈ 50–75 years Zn-Al + polymer in many temperate sites (real-world use may vary).

- Industries: hydraulic works, road and rail cuts, mining tailings, coastal revetments, landscape architecture.

Typical specifications

| Parameter | Common Options (≈) | Notes |

|---|---|---|

| Mesh opening | 60×80, 80×100, 100×120 mm | Double-twist hexagonal |

| Core wire diameter | 2.2–3.9 mm | Selvedge: +0.5–0.9 mm |

| Coating | Zn 230–275 g/m²; Zn-Al; PVC/PE 0.5–1.0 mm | Meets ASTM A975 Type 1–3 |

| Tensile strength | ≥ 350 MPa (wire) | Per EN 10223-3 |

| Box sizes | 2×1×1 m; 3×1×1 m; custom | Diaphragms every 1 m |

Where it performs best

Slope trims on highways, riverbank toes, culvert outlets, and retaining walls where drainage is as critical as mass. The porous structure relieves hydrostatic pressure—fewer weep holes, fewer surprises. As one site supervisor told me, “The Hexagonal Gabion is boring in the best way. It just works.”

Case snapshots

- Riverbank, Southeast Asia: 2 km revetment with 80×100 mm mesh, Zn-Al + PVC. Post-monsoon inspections over 3 seasons: no cage rupture; minor rock settlement only.

- Rail cutting, Eastern Europe: stepped Hexagonal Gabion wall, 6 m total height. Frost-thaw cycles severe; polymer-coated selvedge held geometry better than older plain-galv segments nearby.

Vendor landscape (quick compare)

| Vendor Type | Lead Time | Certs/Standards | Customization | Indicative Cost |

|---|---|---|---|---|

| Anping factory-direct | ≈ 2–4 weeks | ASTM A975, EN 10223-3, ISO 9001 | High (mesh, coating, sizes) | $ (economical) |

| Trading house | 3–6 weeks | Varies by OEM | Medium | $$ |

| Local fabricator | 1–3 weeks | Project-based | Low–Medium | $$$ |

To be honest, I still prefer factory-direct when specs are tight and documentation matters.

Customization and submittals

Mesh opening, wire gauge, Zn or Zn-Al coating class, PVC/PE thickness, box geometry, diaphragms—tunable. Submittals typically include mill test reports, coating certificates, salt-spray data, and a layout/anchorage plan. Ask for weld-free double-twist continuity at edges for better energy dissipation, especially in rivers.

Final thought

The Hexagonal Gabion isn’t flashy. But for resilient, drainable earthworks, it’s still the benchmark—especially with heavy galvanizing and polymer topcoats. As always, rock quality and proper lacing/closure make or break performance.

Authoritative citations

- ASTM A975/A975M – Standard Specification for Gabions (Double-Twisted Hexagonal Wire Mesh).

- EN 10223-3 – Steel wire and wire products for fencing and netting – Part 3: Hexagonal steel wire mesh products.

- EN 10244-2 – Steel wire and wire products – Non-ferrous metallic coatings on steel wire – Part 2: Zinc or zinc-alloy coatings.

- ISO 9227 / ASTM B117 – Corrosion tests in artificial atmospheres (salt spray tests).

- FHWA HEC-23 – Bridge Scour and Stream Instability Countermeasures (gabions and mattresses for channel stabilization).

-

Durable Fence Barbed Wire Solutions for Global Security & Agriculture

NewsNov.24,2025

-

Comprehensive Guide to Barbed Fence Wire – Durability, Uses & Innovations

NewsNov.23,2025

-

Barb Wire Price Per Roll – Understanding Costs, Trends & Global Applications

NewsNov.22,2025

-

Stainless Steel Barbed Wire: Durable Security for Global Industries & Relief Efforts

NewsNov.22,2025

-

Comprehensive Guide to Razor Wire Prices: Factors, Trends & Vendors

NewsNov.21,2025

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025