-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Kas . 23, 2024 21:44 Back to list

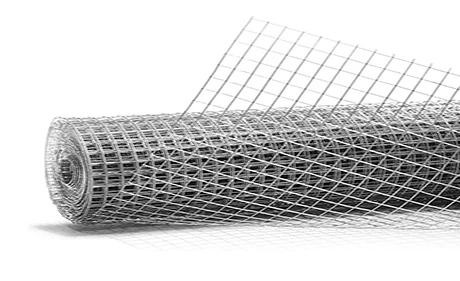

diamond mesh factory

The Evolution and Importance of Diamond Mesh Factory in Today’s Industry

In the bustling world of manufacturing, the diamond mesh factory stands out as a significant player in producing high-quality mesh products used across a wide range of industries. Diamond mesh, characterized by its unique diamond-shaped openings, offers remarkable strength, flexibility, and durability. This article delves into the importance of diamond mesh and how modern factories have revolutionized its production to meet the growing demands of various sectors.

What is Diamond Mesh?

Diamond mesh refers to a type of wire mesh characterized by its distinct diamond-shaped mesh openings. It is typically made from materials such as stainless steel, galvanized steel, and other alloys, ensuring resistance to corrosion, rust, and wear. The diamond pattern provides increased tensile strength compared to other mesh configurations, making it ideal for applications requiring durability and reliability.

This versatile product is used in numerous fields, such as construction, agriculture, fencing, and even security. Its applications range from building safety nets to animal enclosures, and from decorative fencing to providing support in plants and gardens.

The Role of Diamond Mesh Factories

Diamond mesh factories play a pivotal role in the production of these essential materials. The evolution of manufacturing technologies has allowed for increased efficiency and precision in the production process. Modern diamond mesh factories employ advanced machinery and automation systems, ensuring that products are manufactured to exact specifications and within tight tolerances.

One of the core advantages of these factories is their ability to adapt to the specific needs of their clients. Whether it’s customizing the wire gauge, the size of the openings, or the overall dimensions of the mesh, manufacturers can tweak their production processes to create bespoke solutions. Additionally, these factories often maintain stringent quality control measures, ensuring that every roll of mesh produced meets industry standards and safety regulations.

Eco-Friendly Practices

diamond mesh factory

As the world shifts towards sustainability, many diamond mesh factories are adopting eco-friendly practices to reduce their environmental impact. This includes utilizing recycled materials in their production processes, minimizing waste, and implementing energy-efficient manufacturing techniques. By prioritizing sustainability, these factories not only contribute to environmental conservation but also appeal to an increasingly eco-conscious consumer base.

The Global Market Demand

The demand for diamond mesh products has seen a significant increase on a global scale, driven primarily by urbanization and industrial growth. As cities expand, the need for effective fencing, safety, and structural support systems continues to rise. This trend is further amplified by the growth of the agriculture sector, where diamond mesh is used extensively in crop protection and animal husbandry.

Moreover, the construction industry has recognized the advantages of diamond mesh in enhancing building safety and structural integrity. As various industries continue to grow and evolve, the diamond mesh factory remains essential for ensuring that the supply chain effectively supports this demand.

Innovation and Future Trends

Looking ahead, the diamond mesh factory industry is poised for innovation. Research and development are continuously paving the way for new materials and production methods that further enhance the performance of diamond mesh products. Adding features such as UV resistance, enhanced durability treatments, and smart technology integration could open up new applications and markets.

Moreover, the digital transformation of industries is also impacting diamond mesh production. Companies are increasingly leveraging data analytics and Internet of Things (IoT) technology to optimize manufacturing processes and enhance operational efficiency.

Conclusion

In conclusion, diamond mesh factories represent a critical component of modern manufacturing, driven by technological advancements and evolving market demands. Their ability to produce durable, versatile, and customized mesh solutions has cemented their place in numerous industries. As these factories continue to innovate and adapt to sustainability trends, they will undoubtedly play a vital role in shaping the future of manufacturing and industry. Through quality production and eco-friendly practices, diamond mesh factories are set to thrive in the global market, ensuring businesses receive the reliable products they need to succeed.

-

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

NewsAug.14,2025

-

Premium Rib Lath for Durable Stucco & Plaster Systems

NewsAug.13,2025

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025