-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 19, 2025 12:05 Back to list

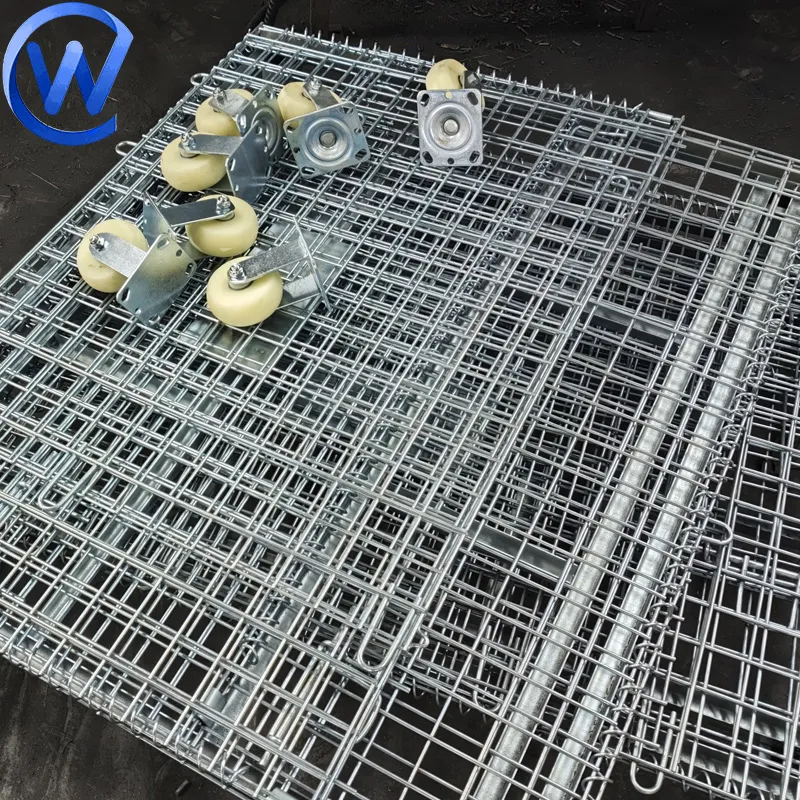

Storage Cage: Heavy-Duty, Stackable, Foldable & Secure

What I’m Seeing in Storage Cages Right Now: Trends, Specs, and Real-World Notes

A few years ago, I thought cages were just cages—then I visited South Industrial Zone 07, Anping County, Hebei, China, and watched hot-dipped frames roll out like clockwork. The market for Storage Cage solutions has shifted: buyers want collapsible, stackable, and frankly, gear that shrugs off abuse. Steel prices move, labor is tight, and replacement cycles are under the microscope. In this context, heavy-duty welded wire containers are having a moment.

Why this format works

Collapsible frames save backhaul costs. Hot-dip galvanizing resists rust in wet docks and gritty workshops. And the welded mesh—50×50 or 50×100—keeps visibility high for cycle counts. Many customers say they switched to Storage Cage units to reduce damage in bulk handling of tires, auto parts, and returnable packaging. Surprisingly, retailers love them for wine and seasonal goods, because barcodes stay visible.

Typical specifications (real-world values may vary)

| Parameter | Typical Value | Notes |

|---|---|---|

| Mesh size | 50×50 mm or 50×100 mm | Choose based on SKU size/labels |

| Wire diameter | ≈ 5–6.5 mm | Heavier wire = higher load |

| Finish | Hot-dip galvanized | To ISO 1461 / ASTM A123 |

| Static / dynamic load | ≈ 1500–2000 kg / 800–1200 kg | Application-dependent |

| Stacking | 3–4 high (static) | Check floor rating and safety rules |

Materials, process, and testing

- Materials: low-carbon steel wire and channel framing; reinforced feet for forklift entry.

- Methods: resistance spot welding; pickling; fluxing; hot-dip galvanizing with zinc layer ≈ 70–100 μm for corrosion protection.

- Testing: load verification to ANSI MH26.2-like procedures; weld shear tests (>2.5 kN at critical joints is common); salt-spray to ISO 9227 (480–720 h reported for heavy zinc); hinge cycle tests (≈10,000 folds).

- Service life: around 8–12 years indoor; coastal or chemical exposure may shorten it (still better than paint, to be honest).

- Certifications: ISO 9001 quality systems; material RoHS/REACH declarations on request.

Where they’re used

Workshops and automotive reman plants, 3PL hubs, supermarkets, tire depots, wineries, sports distributors (balls by the thousands), even firewood yards. The visibility helps with FIFO. And the collapsible frame means your return freight isn’t shipping air. A warehouse manager told me their Storage Cage fleet cut shrink by 12% simply because pickers could see what was inside without opening lids.

Vendor comparison (quick take)

| Criteria | Anping Hot-Dip Supplier | Vendor A (Powder-Coated) | Vendor B (Budget Import) |

|---|---|---|---|

| Corrosion resistance | High (ISO 1461 zinc, 480–720 h SS) | Medium (chips in transit happen) | Low–medium (varies a lot) |

| Load capacity | ≈ 1000–2000 kg | ≈ 800–1500 kg | ≈ 600–1200 kg |

| Lifecycle cost | Low (long service life) | Medium | Uncertain (repairs add up) |

| Customization | Strong: lids, dividers, labels, casters | Limited colors/sizes | Basic, few options |

Customization and ordering tips

Pick your mesh (50×50 for small items; 50×100 for bulky parts). Ask for nameplates, half-drop doors, or bolt-on casters for kitting zones. If you’re storing tires or wine, consider corner protections and tighter mesh at the base. And yes, make sure your floor and racking comply with OSHA/ANSI rules before stacking Storage Cage units four-high.

Mini case study

A regional tire distributor (3 DCs) swapped wood crates for galvanized Storage Cage containers. Result after 9 months: 18% reduction in handling damage, 22% faster cycle counts (visibility!), and two trailers saved monthly on reverse logistics because cages collapse to roughly 25–30% of full height.

Bottom line: if your operation lives with moisture, grit, or constant forklift traffic, hot-dipped welded wire is a safe, boringly reliable pick. Actually, boring is good when uptime is the goal.

Authorities and standards

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles.

- ASTM A123/A123M: Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- ISO 9227: Corrosion tests in artificial atmospheres — Salt spray tests.

- ANSI MH26.2: Design, testing, and utilization of portable racks; OSHA 29 CFR 1910.176 material handling.

-

Durable Fence Barbed Wire Solutions for Global Security & Agriculture

NewsNov.24,2025

-

Comprehensive Guide to Barbed Fence Wire – Durability, Uses & Innovations

NewsNov.23,2025

-

Barb Wire Price Per Roll – Understanding Costs, Trends & Global Applications

NewsNov.22,2025

-

Stainless Steel Barbed Wire: Durable Security for Global Industries & Relief Efforts

NewsNov.22,2025

-

Comprehensive Guide to Razor Wire Prices: Factors, Trends & Vendors

NewsNov.21,2025

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025