-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Лис . 24, 2024 16:53 Back to list

Leading Manufacturer of High-Quality Crimped Mesh for Various Industrial Applications

Understanding Crimped Mesh A Comprehensive Overview of Manufacturers and Applications

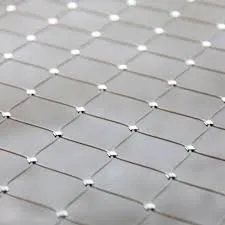

Crimped mesh is a specialized type of woven wire mesh that is known for its unique strength, durability, and versatility in various applications. Often utilized in industries such as construction, mining, and agriculture, crimped mesh provides not only structural support but also plays a crucial role in filtration and separation processes. In this article, we will explore the characteristics of crimped mesh, its various applications, and what to consider when selecting a manufacturer.

What is Crimped Mesh?

Crimped mesh is produced by weaving together wires that have been crimped—essentially bent or zig-zagged—before the weaving process. This crimping adds strength and stability to the mesh, allowing it to maintain its shape under stress. The crimping process can be performed in various patterns, creating different mesh sizes and shapes, which can be tailored to meet specific requirements.

Characteristics of Crimped Mesh

1. Strength and Durability The crimped design enhances the strength of the mesh, making it resistant to deformity and ensuring it can withstand significant loads. This makes it an ideal choice for structural applications.

2. Versatility Crimped mesh can be manufactured from various materials, including stainless steel, mild steel, and aluminum, allowing it to be used in a range of environments, from acidic and high-temperature settings to outdoor applications exposed to the elements.

3. Customization Manufacturers can provide crimped mesh in different wire diameters, crimp patterns, and mesh openings, which can be tailored to the specific needs of a project.

4. Aesthetic Appeal Beyond functionality, crimped mesh can also add a unique aesthetic element to architectural projects. Its industrial style is appealing in modern design, making it a popular choice for decorative applications as well.

Applications of Crimped Mesh

Crimped mesh is used across various sectors due to its functional properties

1. Construction In the building industry, crimped mesh is often used for reinforcing concrete floors, walls, and roofs. It provides the necessary support to withstand structural loads.

2. Mining and Quarrying Crimped mesh is widely utilized for separating materials and in vibrating screens. Its durability allows it to efficiently handle the harsh conditions often found in these environments.

crimped mesh manufacturer

3. Agriculture In agriculture, crimped mesh is used for livestock pens, fencing, and in sorting equipment. It effectively keeps animals secure while allowing for ventilation.

4. Filtration Crimped mesh is employed in various filtration systems, such as water treatment plants and industrial applications, where it effectively separates particles from liquids and gases.

5. Architectural Design Designers increasingly use crimped mesh for decorative facades, railings, and sunshades, combining functionality with aesthetic appeal.

Choosing the Right Manufacturer

When selecting a crimped mesh manufacturer, consider the following factors

1. Expertise and Experience Opt for manufacturers with a proven track record in producing high-quality crimped mesh. Experience in the industry can often translate to better products and services.

2. Customization Options Ensure that the manufacturer can meet your specific requirements in terms of size, material, and design.

3. Quality Control Look for manufacturers that adhere to strict quality control measures to ensure consistency and durability of their products.

4. Reputation Research customer reviews and testimonials to gauge the reputation of the manufacturer in terms of product quality, service, and reliability.

5. Delivery and Support Consider manufacturers that offer robust customer support and timely delivery options. This can be crucial for project timelines.

Conclusion

Crimped mesh is an incredibly versatile and durable material that finds its application across various industries. Understanding its properties and the key factors involved in selecting a reputable manufacturer is essential for maximizing its potential in any project. By considering these elements, you can ensure that you choose the right crimped mesh product that meets your needs effectively.

-

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

NewsAug.14,2025

-

Premium Rib Lath for Durable Stucco & Plaster Systems

NewsAug.13,2025

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025