-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 28, 2025 12:40 Back to list

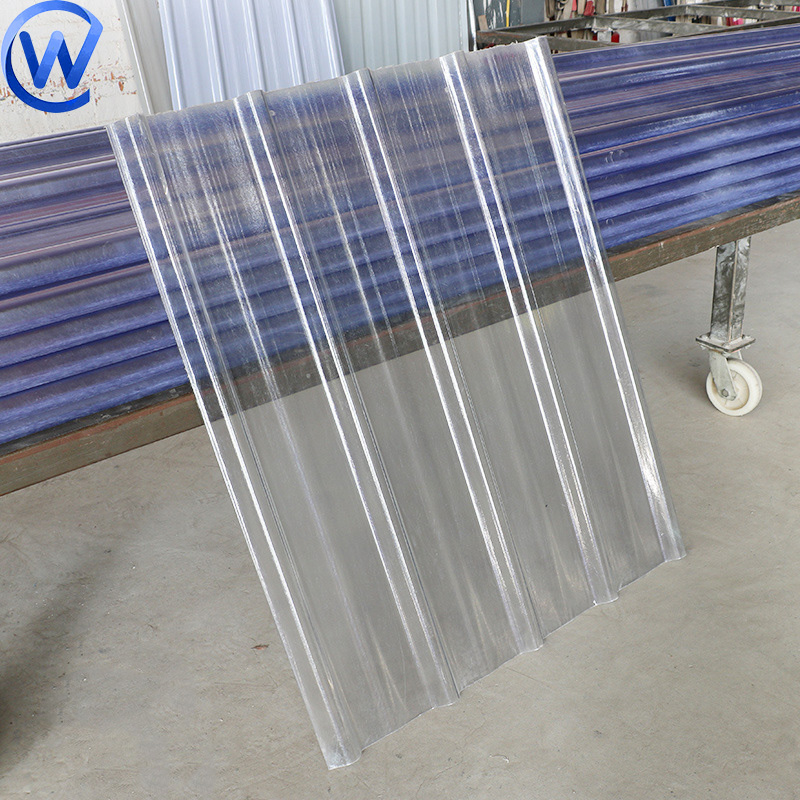

Premium Roof Tiles — Durable, Stylish, Weatherproof

A Field Guide to Roof Tiles for Daylighting Roofs

If you’ve walked through a modern warehouse or a tidy greenhouse at dusk and wondered why it still feels bright, well, that’s the daylighting effect. Today’s translucent Roof Tiles — FRP, PC, PET, and UPVC — are quietly replacing heavy glazing in roofs around logistics hubs, farms, and even stadiums. I’ve toured more than a few plants, and the trend is clear: lighter, tougher, more UV-stable sheets that cut energy bills without turning roofs into maintenance headaches.

What’s inside these sheets (and why it matters)

- FRP (fiberglass reinforced plastic): continuous E-glass mat + polyester resin + UV film. Known for corrosion resistance, stable stiffness, and decent light diffusion. Many customers say it “just holds up” in coastal sheds.

- PC (polycarbonate): extruded solid or corrugated sheet; impact champ, up to ≈85% transmittance, with co-extruded UV layer. Great for hail belts.

- UPVC: good chemical resistance, budget-friendly, consistent color; a touch heavier; thermal expansion needs attention.

- PET: clear and light, recyclable; better for cost-driven retrofits where extreme impact isn’t required.

Process, briefly: resin compounding or pellet drying → extrusion or continuous lamination → UV co-extrusion/film → corrugation/profile forming → trimming → QA (optical transmittance, impact, flammability, weathering). Serious makers test to ASTM D3841 (FRP panels), ASTM E84 (surface burning), UL 94 (flammability), EN 16153 (PC sheet), and UV weathering by ASTM G154. To be honest, the lab data tells you who’s cutting corners.

Specification snapshot

| Parameter | FRP Lighting Tile | PC Lighting Tile | UPVC Lighting Tile | PET Lighting Tile |

|---|---|---|---|---|

| Typical thickness | 1.0–3.0 mm | 0.8–2.0 mm | 1.5–3.0 mm | 0.6–1.2 mm |

| Light transmittance | ≈60–78% | up to ≈85% | ≈25–35% | ≈75–85% |

| Impact (Izod, notched) | ≈100–300 J/m | ≈600–850 J/m | ≈50–120 J/m | ≈300–500 J/m |

| Thermal expansion | ≈20–30×10⁻⁶/K | ≈65×10⁻⁶/K | ≈80×10⁻⁶/K | ≈70×10⁻⁶/K |

| Flame rating (UL 94) | V-2/V-0 (option) | V-2/V-0 (option) | V-0 (common) | HB–V-2 (varies) |

| Service life (field) | 15–25 yrs | 10–20 yrs | 10–15 yrs | 5–10 yrs |

Values are typical; real-world use may vary by formulation, thickness, and environment.

Applications I’m seeing most

- Warehouses and last‑mile hubs (daylight strips on metal roofs).

- Poultry and dairy buildings (FRP over corrosive atmospheres).

- Greenhouses and garden centers (PC/PET for high clarity).

- Transit stations, sports bleachers, and atriums (impact + light). To be honest, PC shines here — pun intended.

Vendor comparison (quick, practical)

| Vendor | Strengths | Lead Time | Certs/Standards | Price Level |

|---|---|---|---|---|

| Anping, Hebei manufacturer (South Industrial Zone 07) | FRP/PC focus, custom corrugations, UV film options | ≈10–20 days | ISO 9001; tests to ASTM/EN/UL | Mid |

| Regional importer A | Local stock, small MOQs | Immediate–7 days | Varies by batch | Mid–High |

| Value supplier B | Economy lines, basic profiles | ≈15–30 days | Entry-level | Low |

Customization and install notes

Profiles: corrugated or trapezoidal to match metal sheets; colors: clear, ice, opal, blue; UV layers: one or two sides; flame class on request. Fasteners with oversized holes + EPDM washers help with expansion. I guess it’s obvious, but specify purlin spacing with wind/snow per ASCE 7 and ask for load tables.

Mini case notes

- Poultry shed, coastal region: FRP daylights cut daytime lighting hours; facility team reported ≈12% electricity reduction year one (weather-dependent).

- Cross-dock warehouse: PC skylight belts survived a hail event; only edge gaskets needed replacement — surprisingly resilient.

Roof Tiles from South Industrial Zone 07, Anping County, Hebei, China, are regularly shipped with QA packs: transmittance (ASTM D1003), flammability (UL 94), weathering (ASTM G154), and E84 for surface burning. Customers say the documentation “makes approvals faster.” Fair point.

Final checklist

- Choose FRP for corrosion, PC for impact/clarity, UPVC for budget/chemicals, PET for light retrofits.

- Ask for UV layer thickness and verified test reports.

- Confirm fixing details and thermal movement. Small detail, big difference.

- ASTM D3841 — Standard Specification for Glass-Fiber-Reinforced Polyester Plastic Panels.

- EN 16153 — Plastics: Light transmitting flat extruded polycarbonate (PC) sheets.

- ASTM E84 — Standard Test Method for Surface Burning Characteristics of Building Materials.

- UL 94 — Tests for Flammability of Plastic Materials for Parts in Devices and Appliances.

- ASTM G154 — Standard Practice for UV Exposure of Nonmetallic Materials.

-

Barbed Wire Fence: Durable Security Solutions for Global Agriculture and Industry

NewsNov.19,2025

-

Barbed Wire: Durable & Affordable Security Solutions for Global Applications

NewsNov.18,2025

-

Durable and Cost-Effective Fence Wire Mesh for Farm Sheep – Global Insights & Innovations

NewsNov.18,2025

-

Durable and Cost-Effective Farm Fencing Wire Galvanized | Global Use & Benefits

NewsNov.15,2025

-

Essential Guide to Wire for Fencing: Applications & Innovations

NewsNov.14,2025

-

Durable Fence Security Wire Solutions for Industrial Use | Galvanized Mesh Products

NewsNov.14,2025