-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 05, 2025 03:40 Back to list

Premium Security Window Screen Mesh | Unmatched Safety

Security Window Screen Mesh represents the new generation of architectural safety and intrusion prevention mesh widely adopted in modern residential, commercial, and industrial buildings. Engineered to deliver robust physical protection while maintaining optimal airflow and visibility, it has become an industry benchmark for secure window installation and high-end safety applications worldwide.

Market Trends: According to the 2023 Global Window Security Mesh Industry Report (source: Grand View Research), the market for high-security mesh solutions is projected to grow at a CAGR of 5.8% from 2023 to 2028, with demand driven primarily by urban security upgrades and evolving architectural standards. Sectors such as petrochemical, metallurgy, water treatment, and smart buildings are among the top users.

- Major standards: ISO 9001, ISO 9227 (Corrosion Testing), ANSI/BHMA A156.36, ASTM E2016/E2016M.

- Core materials: Stainless Steel 304, 316, 316L; powder-coated galvanized steel.

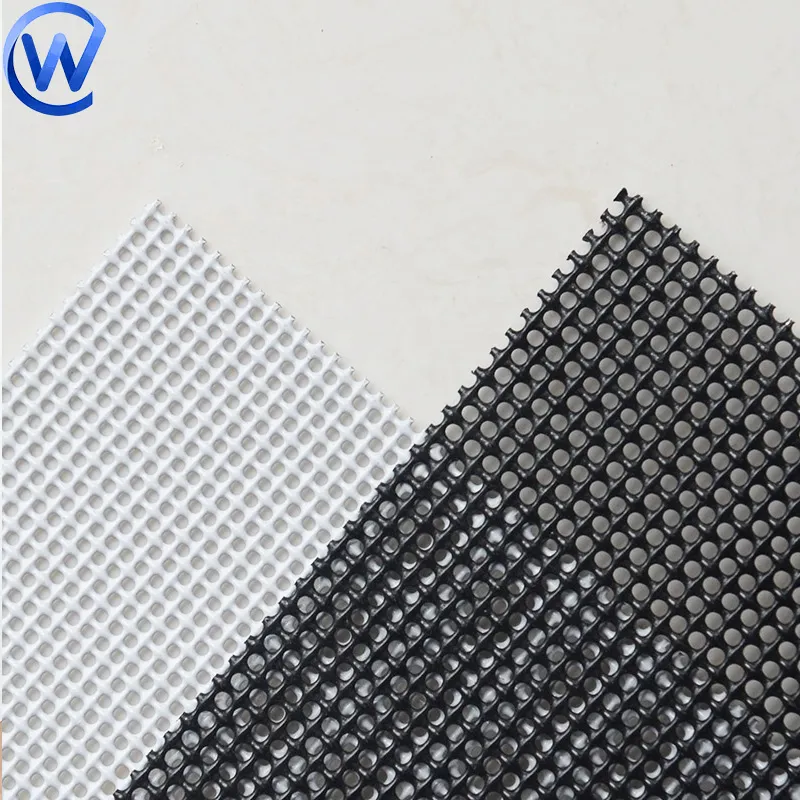

- Mesh aperture: 0.5-2 mm (customized for anti-intrusion & anti-mosquito needs).

- Surface finish: Electrophoresis, electrostatic powder coating, anodizing.

- Key advantages: Tamper resistance, corrosion protection, fire resistance, and particle filtration.

The manufacturing cycle of Security Window Screen Mesh is subject to rigorous technical standards and multi-point inspection, typically consisting of the following phases:

- Raw Material: Selection of Grade 304/316 Stainless Steel or Galvanized Steel (ISO Certified).

- Wire Drawing & Annealing: Ensures tensile strength & corrosion resistance.

- Mesh Forming: Precision weaving/welding (straight-through weave, twilled, or spot-welded mesh).

- CNC Cutting/Punching: High-accuracy cuts ensure perfect fit & edge integrity.

- Surface Coating/Anodizing: Powder coating or anodizing for enhanced chemical durability.

- Quality Testing (ISO, ANSI): Inspections for mesh aperture accuracy, tensile, corrosion, and finish uniformity.

- Final Packaging: Eco-friendly wraps, strict labeling/control (meets export standards).

- ISO 9001: Quality Management Systems Certification

- ISO 9227: Corrosion Resistance Salt Spray Test (>1000h for powder-coated mesh)

- ANSI/BHMA A156.36 (US physical security standard for mesh access panels)

- Compliance with ASTM E2016 (mesh aperture and thread measurement standards)

- FDA non-toxicity test (for food plant or medical environment mesh)

| Property | Stainless 304 | Stainless 316 | 304 Powder Coated | Galvanized Steel |

|---|---|---|---|---|

| Wire Diameter | 0.7 - 1.2 mm | 0.7 - 1.2 mm | 0.7 - 1.2 mm | 0.6 - 1.0 mm |

| Mesh Size (Aperture) | 11 × 11 mesh/inch | 11 × 11 mesh/inch | 10 × 10 & 11 × 11 mesh/inch | 8 × 8 mesh/inch |

| Open Area (Airflow) | 58% ~ 69% | 58% ~ 69% | 53% ~ 65% | 56% |

| Tensile Strength (MPa) | ≥ 900 | ≥ 920 | ≥ 880 | ≥ 450 |

| Corrosion Resistance | Excellent (pass 1000h NSS) | Best (pass 1200h NSS) | Excellent (pass 1200h NSS) | Good (pass 300h NSS) |

| UV Stability | Natural | Natural | Excellent | Good |

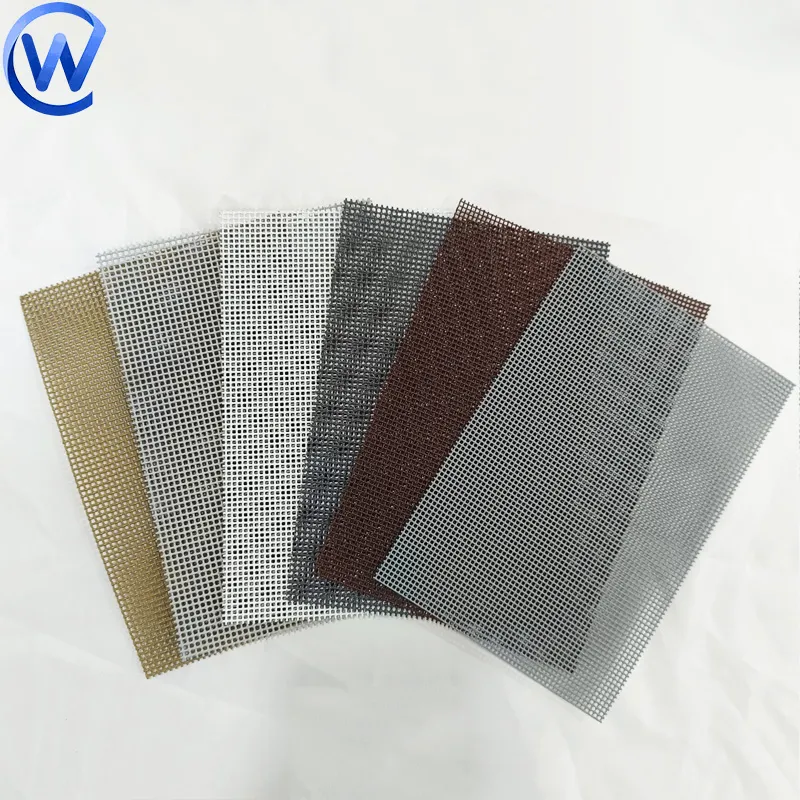

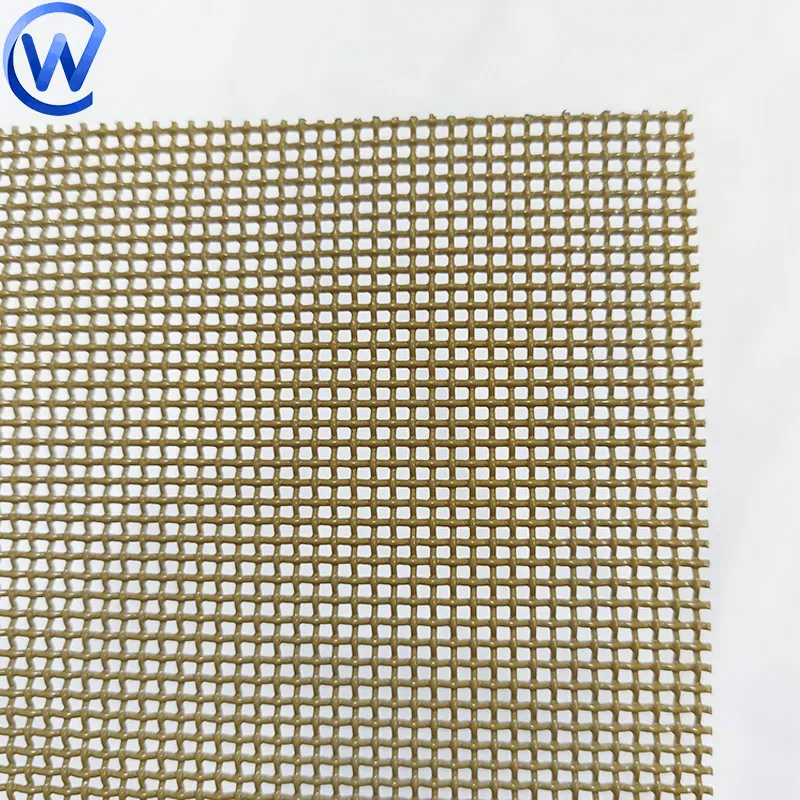

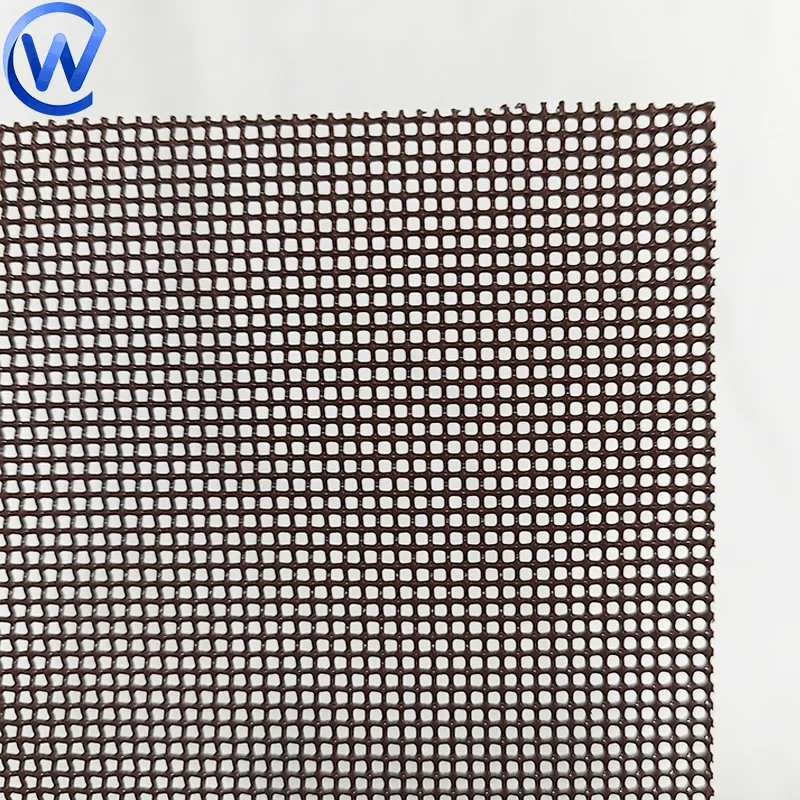

| Standard Colors | Natural Silver | Natural Silver | Black, Bronze, Grey | Silver, Black |

| Fire Rating | UL94 V-0 | UL94 V-0 | UL94 V-0 | UL94 V-1 |

| Typical Width Range | 0.8m – 1.5m | 0.8m – 1.5m | 0.6m – 1.8m | 0.6m – 1.2m |

| Service Life | > 20 years | > 25 years | 15–20 years | 8–12 years |

Security Window Screen Mesh Applications: This advanced mesh provides high-end protection in environments requiring strict physical security as well as environmental resilience:

- Smart Buildings, High-end Apartments: Anti-burglary and anti-vandal security without sacrificing view or ventilation.

- Petrochemical & Power Plants: Prevent unauthorized entry and resist harsh corrosive atmospheres (H2S, chlorine).

- Food & Pharma Processing: FDA-compliant for hygiene-critical installation, blocks insects/particles.

- Data Centers, Server Room Protection: Mesh prevents physical tampering and meets fire safety codes.

- Water Supply & Treatment Facilities: Prevents debris, birds, or pests while supporting long-term moisture and corrosion resistance.

- Transport Hubs & High-risk Public Spaces: Used for windows, partitions, and access panels in airports, stations, embassies, banks, schools, and hospitals.

- Unobtrusive Strong Barrier: Withstand blade, impact, and crowbar attacks without visually blocking interior/exterior.

- Corrosion and Fireproof: Surfaces pass strict ISO 9227 salt spray test (up to 1200 hours). Fire resistance to UL94 V-0 class, with no melting or deformation.

- Easy Retrofit & Maintenance: Custom sizes and modular design ensure easy upgrade/repair vs. old window mesh.

- Safety & Energy Saving: Mesh enables natural airflow, reducing HVAC costs by up to 15% for ventilated areas (source: U.S. Department of Energy building studies, 2022).

- Environmental Compliance: RoHS, CE, and FDA certifications available, supporting "green building" and sustainable procurement.

| Manufacturer | Material Options | ISO Certified | Custom Services | Min Delivery Time | Main Export Markets |

|---|---|---|---|---|---|

| GalvanizedMeshProducts | SS304, SS316, GS, Custom Color | ISO 9001, ISO 9227 | OEM/ODM, Logo, Size, Package | 7 Days | USA, EU, AU, MENA, SEA |

| MeshGuard Corporation | 304, 316, Aluminum Alloy | ISO 9001 | Basic (Size Only) | 15 Days | EU, US, Russia |

| SecureMesh Intl. | SS304, 316L | ISO 9001, CE | Brand Label, Custom Frame | 20 Days | Australia, South Africa |

| StrongShield HK | Powdered 304, GS | ISO 9001 | Color & Surface Options | 12 Days | HK, SEA, Oceania |

Customization Options: Security Window Screen Mesh can be tailored by mesh aperture, wire diameter, color, panel size, and frame integration. Anti-cut, anti-theft, and anti-insect grades are available based on project technical drawings and on-site measurement.

- Send requirement/specification or shop drawing

- Technical consulting & free sample provision

- Pilot batch production & certification tests (ISO/CE/ANSI)

- Final batch mass-production (lead time: 7–20 days)

- Packing, export customs and global delivery

Quality Guarantee: 10-year minimum warranty, with full technical support and immediate spare part replenishment.

- Supplied 316 anti-theft mesh for 2,300 windows; all panels custom powder-coated in architectural black.

- ISO and ANSI test vouches provided for every batch.

- Result: Zero forced entry incidents, reduced HVAC energy by 11%.

Client feedback: "Stability and peace of mind. No corrosion after 20 months!"

- Delivered salt-spray-tested 316 mesh to withstand H2S-rich atmosphere.

- Operated above 50°C for 2 years: no mesh shrink, rusting or visible wear.

- Client satisfied with physical access control and plant hygiene upgrades.

- Q1: What is the most recommended material for Security Window Screen Mesh in coastal areas?

- A: 316 stainless steel is best for marine or high-humidity zones, offering superior corrosion resistance (thanks to molybdenum content) and a >20-year lifespan per ISO9227.

- Q2: What is the aperture, and how does it affect security?

- A: Aperture (the clear opening between wires) dictates what can pass through the mesh. Sizes between 1.0–2.0 mm are optimal for security (anti-tool/knife) and pest exclusion.

- Q3: What installation standards must be met for anti-theft certification?

- A: Mesh must be frame-mounted with anti-pry fasteners, pass ANSI/BHMA A156.36 and ASTM E2016 impact testing, with documented fixings and no loose edges over 3 mm.

- Q4: What is powder coating, and how does it improve mesh durability?

- A: Powder coating is an advanced dry finishing process that applies polyester or epoxy powder, then cures. This enhances corrosion resistance, UV stability, and color uniformity.

- Q5: What about mesh cleaning and regular maintenance?

- A: Clean with mild soap and water using a soft cloth; avoid acids or abrasives. Most certified mesh requires only biannual cleaning for optimal transparency and function.

- Q6: Are there anti-bacterial or food-grade mesh options?

- A: Yes. 304/316 stainless mesh can be FDA and RoHS certified, and special medical or pharmaceutical variants are manufactured under ISO 13485/14001 systems.

- Q7: What is the warranty and customer support guarantee?

- A: GalvanizedMeshProducts offers up to 10-year written warranty, technical compliance records, and 24/7 after-sales support backed by over 15 years’ export and service experience.

- Cited by Construction Specifications Institute (CSI), "Section 08520: Windows Protective Screens", Read more

- Referenced in International Stainless Steel Forum (ISSF) Technical Bulletin, "Stainless Mesh for Safety Applications", View Bulletin

- Peer-reviewed in "Advances in Building Materials" (J. of Construction Materials, 2022, No.4) – "The Efficacy of Stainless Window Mesh in Anti-Intrusion Design", See Article

- "Window Screen Security Mesh for Building Applications," SecurityInfoWatch Community Forum, Community Insights

Security Window Screen Mesh stands as the preferred solution worldwide for next-generation safe and sustainable building envelopes, consistently endorsed by standardization authorities and specifier communities.

-

Barbed Wire Fence: Durable Security Solutions for Global Agriculture and Industry

NewsNov.19,2025

-

Barbed Wire: Durable & Affordable Security Solutions for Global Applications

NewsNov.18,2025

-

Durable and Cost-Effective Fence Wire Mesh for Farm Sheep – Global Insights & Innovations

NewsNov.18,2025

-

Durable and Cost-Effective Farm Fencing Wire Galvanized | Global Use & Benefits

NewsNov.15,2025

-

Essential Guide to Wire for Fencing: Applications & Innovations

NewsNov.14,2025

-

Durable Fence Security Wire Solutions for Industrial Use | Galvanized Mesh Products

NewsNov.14,2025