-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ديسمبر . 17, 2024 22:39 Back to list

12.5 gauge barb wire factories

Understanding 12.5% Gauge Barb Wire and Its Manufacturing Process

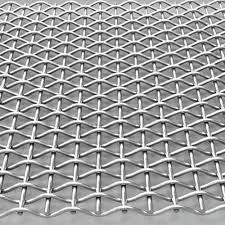

Barbed wire has been an essential component in the agricultural and security sectors for many decades. Among the various types of barbed wire, the 12.5% gauge barb wire is particularly notable for its strength, durability, and effectiveness in confinement. This article delves into the characteristics, advantages, and manufacturing processes of 12.5% gauge barb wire, shedding light on the factories that produce this vital material.

What is 12.5% Gauge Barb Wire?

The term gauge refers to the thickness of the wire used in the fabrication of barbed wire. A 12.5% gauge wire corresponds to approximately 2.0 mm in thickness, making it a robust option for various applications. The barbs, typically spaced about 5 to 6 inches apart, are designed to deter animals and intruders alike. Commonly used in fencing for livestock, agricultural fields, and property boundaries, this wire effectively serves both protective and delineative purposes.

Advantages of 12.5% Gauge Barb Wire

1. Strength and Durability The primary advantage of 12.5% gauge barb wire is its strength. The thicker wire can withstand significant tension and pressure, making it suitable for demanding environments. This durability translates to a longer lifespan, minimizing the need for frequent replacements, and ultimately providing cost efficiency.

2. Security The barbs on the wire create a barrier that is difficult for animals and intruders to cross. This makes 12.5% gauge barb wire an effective deterrent against unauthorized access to properties and keeps livestock safely contained.

3. Versatility This type of barbed wire can be used in various settings—from farms and ranches to residential areas. Its adaptability makes it a popular choice for many fence installations.

Manufacturing Process of 12

.5% Gauge Barb Wire12.5 gauge barb wire factories

The production of 12.5% gauge barb wire occurs in several stages, primarily within specialized factories that focus on wire manufacturing. Here’s an overview of the key steps involved in its production

1. Raw Material Preparation The manufacturing process begins with the selection of high-quality steel wire. The wire is then coated with zinc to prevent rust and corrosion, enhancing its longevity and suitability for outdoor use.

2. Drawing The raw wire is drawn through a series of dies to achieve the desired gauge thickness. For 12.5% gauge wire, this process ensures consistent thickness and high tensile strength.

3. Barb Formation The next step involves the creation of the barbs. This is typically accomplished using a specialized machine that twists and shapes the wire at predetermined intervals. Each barb is designed to be sharp and effective, contributing to the overall security of the wire.

4. Spooling Once the barb wire has been formed, it is wound onto spools for easy transportation and installation. This spooling process ensures that the wire remains tangle-free, facilitating prompt use in fencing applications.

5. Quality Control Before distribution, factories conduct rigorous quality checks. These assessments include tensile testing and inspections for defects, ensuring that the final product meets industry standards.

Conclusion

The 12.5% gauge barb wire has established itself as a pivotal product in fencing and security. Its robust characteristics and effectiveness make it a preferred choice for farmers, landowners, and security professionals. The manufacturing process, occurring in specialized factories dedicated to wire production, involves meticulous care and precision to ensure a high-quality end product. Whether used in agricultural settings or for enhancing property security, this type of barb wire continues to serve as a reliable solution for various needs, demonstrating its enduring value in today's world.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025