-

+86 15030157877

-

sales@galvanizedmetalmesh.com

سبتمبر . 26, 2024 00:39 Back to list

12.5% Gauge Barb Wire Production Facility Overview and Specifications

The Essential Role of 12.5% Gauge Barb Wire in Modern Fencing Solutions

In today’s fast-paced world, security and safety have become paramount, leading to increased reliance on effective fencing solutions across various sectors. Among the multitude of options available in the market, 12.5% gauge barb wire stands out as a robust choice for both residential and commercial applications. This article delves into the characteristics, benefits, and applications of 12.5% gauge barb wire produced by specialized factories.

Understanding Gauge and Specifications

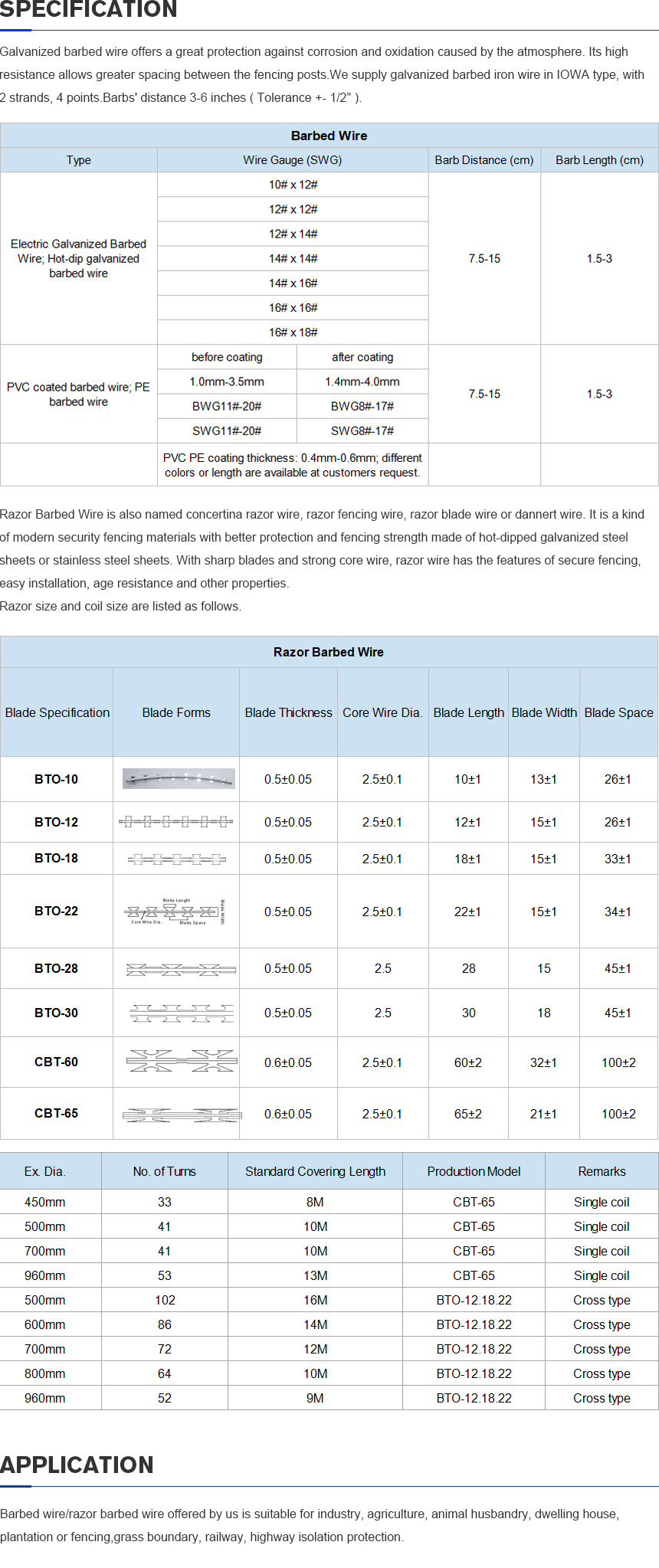

The term “gauge” in wire manufacturing refers to the thickness of the wire, with a higher gauge number indicating a thinner wire. The 12.5% gauge barb wire is known for its balance of strength, flexibility, and affordability. Typically made from high-quality galvanized steel, this particular gauge offers enhanced durability and resistance to corrosion. The factory production process ensures consistent quality, making it reliable for various fencing needs.

Key Benefits of 12.5% Gauge Barb Wire

1. Security Enhancement The primary purpose of barb wire is to deter trespassers and to provide a formidable barrier for properties. The sharp barbs, strategically spaced along the wire, serve as an effective deterrent against intrusion, making it harder for individuals or animals to breach the perimeter.

2. Cost-Effectiveness Compared to other fencing materials, 12.5% gauge barb wire offers a cost-effective solution. It provides similar security benefits at a fraction of the cost compared to traditional fencing options, such as brick walls or wooden fences.

12.5 gauge barb wire factory

3. Versatility This type of barb wire is incredibly versatile and can be used in various settings, including farms, construction sites, and commercial properties. Its lightweight nature makes it easy to install while ensuring adequate strength to maintain its form under stress.

4. Low Maintenance One of the significant advantages of opting for galvanized barb wire is its low maintenance requirements. The galvanization process protects the wire from rust and degradation, allowing it to withstand harsh weather conditions without frequent repairs.

Applications in Various Industries

12.5% gauge barb wire finds extensive applications across multiple sectors. In agricultural settings, it is commonly used to secure livestock enclosures, preventing animals from escaping and keeping predators at bay. In urban areas, it is employed in surveillance and security setups for warehouses, factories, and residential properties. The construction industry also benefits from using barb wire to delineate job sites and protect valuable equipment.

Conclusion

In conclusion, the 12.5% gauge barb wire, produced by specialized factories, exemplifies a practical and efficient fencing solution for modern needs. Combining strength, affordability, and versatility, it addresses security challenges across various industries while remaining low maintenance. As we continue to prioritize safety in our environments, barb wire remains an essential component of effective fencing solutions.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025