-

+86 15030157877

-

sales@galvanizedmetalmesh.com

نوفمبر . 24, 2024 14:11 Back to list

chicken wire mesh roll factories

Exploring Chicken Wire Mesh Roll Factories A Comprehensive Overview

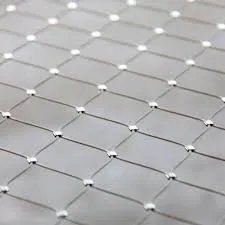

Chicken wire mesh rolls are essential materials used in various applications, from poultry farming to gardening and home security. These versatile products are primarily manufactured in specialized factories, where advanced techniques and high-quality materials converge to create durable and reliable mesh rolls.

The Manufacturing Process

The production of chicken wire mesh begins with the selection of raw materials, typically galvanized steel wire or PVC-coated wire. These materials are preferred for their strength and resistance to rust, which ensures longevity, particularly in outdoor environments. The manufacturing process involves several steps, including drawing, weaving, and finishing.

1. Wire Drawing This initial stage consists of pulling the wire through a series of dies, which reduces its diameter and increases its tensile strength. The quality of the wire used directly affects the durability of the final product.

2. Weaving Once the wire is prepared, it is woven into a hexagonal pattern using automated machines. This process can vary depending on the desired mesh size and wire gauge, allowing factories to cater to specific customer requirements.

3. Finishing Touches After weaving, the mesh may undergo additional treatments, such as galvanization or PVC coating. Galvanization involves coating the wire with zinc to prevent rust, while PVC coating enhances aesthetics and provides additional corrosion resistance.

chicken wire mesh roll factories

Quality Control

In chicken wire mesh roll factories, quality control is paramount. Manufacturers employ rigorous testing methods to ensure that the finished products meet industry standards. This includes checking for consistency in mesh size, wire gauge, and overall structural integrity. Quality assurance helps to minimize defects, ensuring that customers receive only the best products.

Applications and Market

The versatility of chicken wire mesh rolls has led to a wide range of applications. In poultry farming, they are used to create enclosures that protect chickens from predators while allowing for ventilation. In gardening, the mesh serves as a barrier against pests and animals, promoting healthy growth. Additionally, it is often used in construction for reinforcement and safety.

The demand for chicken wire mesh rolls is driven by various sectors, including agriculture, landscaping, and construction. As more people embrace sustainable practices and backyard gardening, the market for chicken wire is expected to grow, prompting factories to innovate and improve their manufacturing processes.

Conclusion

Chicken wire mesh roll factories play a crucial role in producing high-quality, versatile products suited for a variety of applications. As they continue to innovate and maintain stringent quality control, these factories contribute significantly to the agriculture and construction industries, ensuring that consumers have access to durable and effective solutions for their needs. Whether for securing poultry or enhancing garden designs, chicken wire remains a staple in many households and businesses around the world.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025