-

+86 15030157877

-

sales@galvanizedmetalmesh.com

أغسطس . 27, 2025 02:00 Back to list

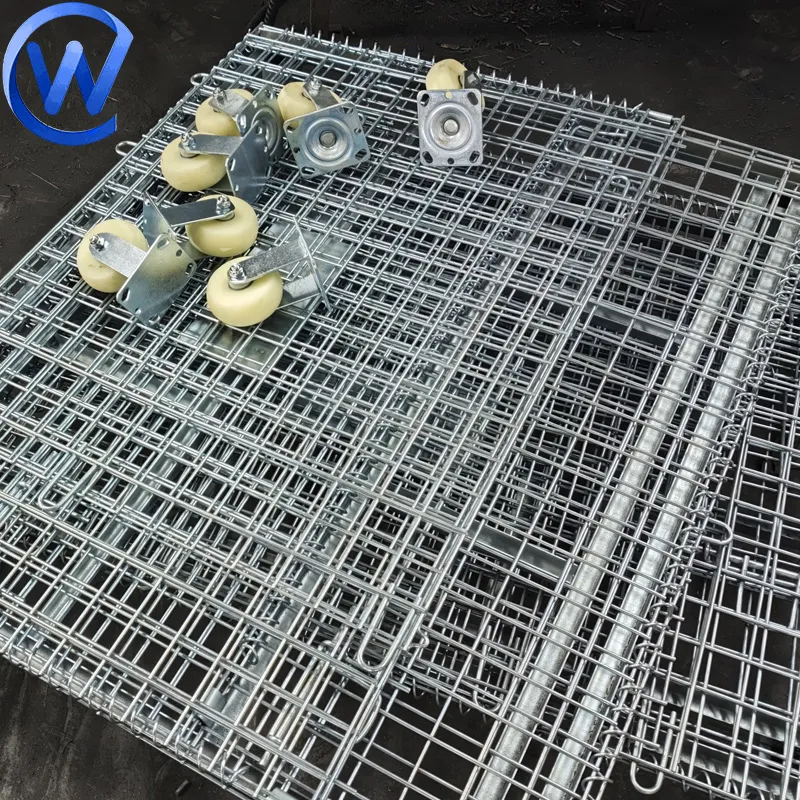

Heavy-Duty Stackable Storage Cages for Efficient Warehouse Storage

In modern industrial and commercial environments, efficient and secure material handling is paramount. The strategic deployment of robust storage solutions significantly impacts operational efficiency, inventory management, and workplace safety. This article delves into the critical role of the Storage Cage, examining its technical specifications, manufacturing processes, diverse application scenarios, and key advantages for B2B decision-makers. We will explore industry trends, offer vendor comparison insights, discuss customization options, and present compelling case studies to underscore its value.

Industry Trends in Material Handling & Storage

The landscape of material handling is continually evolving, driven by demands for greater efficiency, safety, and sustainability. Key trends influencing the adoption and design of industrial storage solutions like the Storage Cage include:

- Automation Integration: Modern warehouses are increasingly integrating automated guided vehicles (AGVs) and robotic systems. Storage solutions must be compatible with these technologies, often requiring standardized footprints and robust construction to withstand automated handling.

- Space Optimization: With rising real estate costs, there's a constant push for higher-density storage. Collapsible and stackable designs for storage units are gaining traction, allowing for maximal utilization of vertical and horizontal space.

- Enhanced Safety Standards: Workplace safety remains a top priority. Storage solutions are expected to comply with stringent safety regulations, featuring secure locking mechanisms, stable stacking capabilities, and clear visibility of contents to prevent accidents.

- Durability and Longevity: Industries demand solutions that offer a long service life, minimizing replacement costs and downtime. This drives the use of high-strength materials and advanced protective coatings, such as hot-dip galvanization, to ensure resistance against corrosion and wear.

- Sustainability: A growing focus on environmental responsibility means preference for products made from recyclable materials and those that contribute to energy efficiency by reducing the need for artificial lighting (due to open mesh designs).

These trends collectively underscore the need for versatile, durable, and cost-effective storage solutions that can adapt to dynamic operational requirements.

Technical Specifications of the Storage Cage

A high-performance Storage Cage is engineered with precision to meet demanding industrial requirements. Understanding its technical parameters is crucial for optimal selection and deployment.

Key Materials and Construction

- Material: Typically constructed from high-tensile steel wire, offering superior strength-to-weight ratio. The primary protective finish is hot-dip galvanization, which provides excellent corrosion resistance as per ASTM A123/A123M standards, ensuring a long service life in various environments, including petrochemical and metallurgical facilities where corrosive agents might be present.

- Mesh Design: Welded wire mesh construction ensures structural rigidity and visibility of contents, facilitating quick inventory checks without opening the unit. Common mesh sizes range from 50x50mm to 100x100mm, optimized for content security and airflow.

- Base: Reinforced steel channel or tube base, designed for forklift and pallet jack accessibility, distributing load evenly and enhancing stability.

- Access: Often features a half-drop gate or hinged access gate for easy loading and unloading, even when stacked.

Standard Product Specifications (Example)

| Parameter | Specification |

|---|---|

| External Dimensions (L x W x H) | 1200 mm x 1000 mm x 890 mm (standard) |

| Internal Dimensions (L x W x H) | 1150 mm x 950 mm x 750 mm |

| Load Capacity | 1000 kg - 1500 kg (dynamic), up to 6000 kg (static stack) |

| Stacking Height | Up to 4-5 units high (when loaded) |

| Mesh Size | 50 mm x 50 mm or 50 mm x 100 mm |

| Wire Diameter | 6.0 mm - 8.0 mm (frame), 4.8 mm - 6.0 mm (mesh) |

| Surface Finish | Hot-dip Galvanized (ASTM A123/A123M), Electro-galvanized, or Powder Coated |

| Weight | Approx. 55 kg - 75 kg (depending on configuration) |

These specifications ensure that the Storage Cage can withstand rigorous industrial usage, providing a reliable and long-lasting solution for diverse material handling needs.

Manufacturing Process Flow for High-Quality Storage Cages

The production of a durable and reliable Storage Cage involves a meticulously controlled manufacturing process, adhering to stringent quality standards to ensure performance and longevity.

Process Steps:

- Material Selection & Preparation: High-grade carbon steel wire rods are selected. These rods undergo a drawing process to achieve the required wire diameters for mesh and frame components. This ensures consistent mechanical properties.

- Wire Cutting & Bending: CNC machines precisely cut the drawn wires to specified lengths for mesh panels, frame components, and base elements. Advanced bending machines then form the structural components, such as the base channels and reinforcement ribs, to exact dimensions.

- Mesh Welding: Individual wires are arranged in a grid pattern and resistance welded at each intersection point. This automated process ensures uniform weld strength and consistent mesh size, critical for structural integrity and load-bearing capacity.

- Frame Assembly & Welding: The welded mesh panels, base frames, and other structural components (e.g., gates, hinges) are assembled using robotic or manual welding techniques. MIG/MAG welding is commonly employed for strong, durable joints.

- Surface Treatment (Hot-dip Galvanization): This is a crucial step for corrosion resistance. The fabricated cage is thoroughly cleaned and degreased, then immersed in a bath of molten zinc at approximately 450°C. This process forms a metallurgical bond between the steel and zinc, creating a highly durable, multi-layered protective coating that resists rust and abrasion. This makes the storage cage ideal for harsh environments common in petrochemical or water supply & drainage sectors.

-

Quality Control & Testing: Throughout the process, strict quality checks are performed.

- Dimensional Accuracy: Verification against CAD drawings.

- Weld Integrity: Visual inspection and, for critical points, destructive testing.

- Galvanization Thickness: Measured according to ISO 1461 or ASTM A123/A123M standards, ensuring adequate protection.

- Load Testing: Sample cages undergo static and dynamic load tests to confirm rated capacities.

- Final Assembly & Packaging: Any collapsible mechanisms or casters are fitted, and the finished Storage Cage is prepared for shipment, often folded to optimize transport volume.

This meticulous process, particularly the hot-dip galvanization, ensures superior corrosion resistance and a service life typically exceeding 10-15 years, even in challenging outdoor or industrial settings, directly contributing to energy saving by reducing replacement needs.

Application Scenarios and Target Industries

The versatility of the Storage Cage makes it an indispensable asset across a broad spectrum of industries, providing effective solutions for material handling, inventory management, and logistics.

- Warehousing & Logistics: Ideal for organizing bulk goods, sub-assemblies, and finished products. Their stackability maximizes vertical storage, while visibility through the mesh allows for quick inventory audits and reduces picking errors.

- Automotive Industry: Used for storing components, spare parts, and engine sub-assemblies. The robust construction protects valuable parts during transport and storage within assembly lines.

- Manufacturing: Facilitates the movement and storage of work-in-progress (WIP) materials, tooling, and scrap. The open design promotes ventilation, crucial for items that require air circulation or are susceptible to moisture.

- Retail & E-commerce: Efficiently manages backroom inventory, seasonal merchandise, or returns. The secure nature of the cages helps prevent loss and damage.

- Recycling and Waste Management: Perfect for segregating and collecting recyclable materials such as plastic bottles, cardboard, or metal scraps before compaction or further processing. The sturdy galvanized finish stands up to harsh, wet conditions.

- Food & Beverage: For non-perishable goods, packaging materials, or empty containers. The open mesh allows for cleanliness and prevents accumulation of dust or debris.

- Pharmaceutical: For storing raw materials or packaged goods that require ventilation and clear identification, adhering to strict organizational standards.

The ability to adapt to diverse operational contexts makes the Storage Cage a highly valuable asset, contributing to streamlined workflows and improved operational safety across various industrial sectors.

Technical Advantages and Operational Benefits

Investing in high-quality Storage Cage solutions offers a multitude of technical and operational advantages that significantly enhance supply chain efficiency and reduce overall costs.

- Superior Durability: Constructed from high-strength steel and typically hot-dip galvanized, these cages offer exceptional resistance to impact, abrasion, and corrosion. This robust construction ensures a longer service life compared to plastic or painted alternatives, even in demanding industrial environments.

- Maximized Space Utilization: The stackable design allows for efficient vertical storage, effectively increasing warehouse capacity without requiring additional floor space. Collapsible models further optimize return logistics and empty storage.

- Enhanced Product Visibility & Accessibility: The open mesh construction provides clear visibility of contents, simplifying inventory checks and reducing the time spent searching for specific items. Half-drop gates or hinged access points ensure easy access to goods even when cages are stacked.

- Improved Airflow & Cleanliness: The open wire mesh design prevents dust and debris accumulation and ensures excellent air circulation. This is critical for storing goods that require ventilation or need to be kept dry, reducing potential for spoilage or degradation.

- Increased Safety & Security: Robust construction and optional locking mechanisms protect valuable inventory from damage or theft. The stable stacking design reduces the risk of collapses and accidents, adhering to occupational safety standards.

- Cost-Efficiency: The long lifespan, minimal maintenance requirements, and ability to optimize space lead to a lower total cost of ownership (TCO). Furthermore, the ability to collapse units for return transport significantly reduces shipping costs for empty cages.

- Compatibility: Designed for seamless integration with standard material handling equipment such as forklifts, pallet jacks, and automated systems, ensuring smooth operational flow.

These advantages collectively contribute to a more organized, safer, and economically efficient material handling operation, making the Storage Cage a strategic investment for any business.

Vendor Comparison: Key Differentiators for Storage Cage Procurement

Selecting the right vendor for industrial storage solutions, such as a Storage Cage, is a critical decision that impacts long-term operational efficiency and cost. B2B decision-makers should evaluate vendors based on several key differentiators beyond just price.

Critical Evaluation Criteria:

- Material Quality and Construction: Verify the grade of steel (e.g., Q235, Q345 for structural components), wire diameter consistency, and the quality of welding. High-quality hot-dip galvanization (e.g., adherence to ISO 1461 / ASTM A123) is crucial for longevity and corrosion resistance.

- Customization Capabilities: Assess the vendor's ability to provide tailored dimensions, load capacities, specialized access points (e.g., removable sides, full-drop gates), casters, dividers, or unique identification features (e.g., nameplate holders).

- Certifications and Compliance: Look for manufacturers with ISO 9001 (Quality Management System) certification. Product-specific compliance with industry standards (e.g., CE marking for European markets, load testing reports) demonstrates commitment to quality and safety.

- Lead Time and Fulfillment: Evaluate the vendor's capacity for timely delivery, especially for large orders or customized solutions. Their logistics capabilities and supply chain robustness are vital.

- After-Sales Support and Warranty: A comprehensive warranty (e.g., 5-10 years against manufacturing defects and excessive corrosion for galvanized products) and responsive customer service are indicators of a reliable partner.

- Experience and Reputation: Longevity in the industry, a portfolio of successful projects, and positive client testimonials provide assurance of a vendor's expertise and reliability.

Vendor Comparison Table (Illustrative Example)

| Feature | Vendor A (Premium) | Vendor B (Standard) | Vendor C (Budget) |

|---|---|---|---|

| Material Grade | Q345 Steel | Q235 Steel | Mixed/Lower grade Steel |

| Surface Finish | Hot-dip Galvanized (ISO 1461) | Electro-galvanized or Painted | Painted or minimal galvanization |

| Max Load Capacity (1200x1000mm) | 1500 kg (dynamic) / 6000 kg (static) | 1200 kg (dynamic) / 4800 kg (static) | 800 kg (dynamic) / 3200 kg (static) |

| Customization | Full, design consultations | Limited, standard options | Minimal or none |

| Certifications | ISO 9001, CE, Load Test Reports | ISO 9001 | Basic internal QA |

| Warranty | 5-10 Years | 2-5 Years | 1 Year (limited) |

This comparison highlights that while a lower initial cost might be appealing, the total cost of ownership, including lifespan, maintenance, and potential operational disruptions, often favors vendors offering superior quality and support for their Storage Cage products.

Customized Solutions for Specific Operational Needs

While standard Storage Cage models serve a wide array of applications, many industrial operations have unique requirements that necessitate customized solutions. Tailored designs can significantly enhance efficiency, safety, and integration with existing infrastructure.

Areas of Customization:

- Dimensions and Capacity: Cages can be engineered to specific length, width, and height requirements to fit unusual products, tight spaces, or integrate with automated systems. Load capacities can be reinforced for exceptionally heavy items.

- Access and Security Features: Custom gate configurations (e.g., full-height hinged doors, multi-panel drop gates, sliding doors) can be implemented. Options for padlock clasps, security seals, or integrated RFID tags enhance security and inventory tracking.

- Internal Organization: Dividers, shelves, or compartments can be added to segregate different types of products within a single cage, optimizing organization and preventing damage.

- Mobility: Heavy-duty casters (swivel, rigid, braking) can be integrated for easy movement within a facility, transforming the static cage into a mobile workstation or transport unit.

- Surface Finish: While hot-dip galvanization is standard, specialized powder coating (in corporate colors, for example) can be applied for aesthetic reasons or additional chemical resistance.

- Specialized Bases: Custom bases can be designed for unique forklift attachments, conveyor system integration, or to accommodate specific types of pallets or skids.

Partnering with a manufacturer experienced in custom fabrication ensures that the final Storage Cage solution perfectly aligns with operational workflows, providing maximum utility and return on investment.

Application Case Studies

Real-world applications demonstrate the tangible benefits of deploying high-quality Storage Cage solutions in diverse industrial settings.

Case Study 1: Automotive Parts Storage in a Tier 1 Supplier

- Challenge: An automotive component manufacturer struggled with inefficient storage of varying-sized parts (from small fasteners to large stamped metal pieces) on the shop floor, leading to clutter, difficulty in inventory tracking, and potential damage.

- Solution: Implemented 500 custom-sized, hot-dip galvanized storage cages with integrated dividers and half-drop gates. These cages were designed to be stackable five high, utilizing vertical space.

-

Results:

- Reduced floor space usage by 30%.

- Improved inventory accuracy by 25% due to enhanced visibility and organization.

- Reduced part damage by 15%, leading to significant material cost savings.

- Faster picking times and smoother material flow to assembly lines.

Case Study 2: Retail Distribution Center Inventory Management

- Challenge: A large retail chain's distribution center faced seasonal fluctuations in inventory, requiring flexible storage for a variety of general merchandise. Existing shelving was rigid and inefficient for bulk items.

- Solution: Deployed 300 collapsible storage cages. During peak seasons, these cages were fully utilized for dense storage. During off-peak, they were collapsed and stored compactly, freeing up valuable floor space.

-

Results:

- Increased storage flexibility by 40%, adapting to seasonal changes.

- Reduced empty storage space costs by 20% during off-peak.

- Faster product identification due to clear mesh sides.

"Implementing these galvanized storage cages transformed our warehouse operations. The durability is unmatched, and the ability to stack them high has given us so much more capacity. It’s a truly robust solution for our heavy components."

Ensuring Trustworthiness: FAQs, Lead Time, Warranty & Support

Building trust with B2B clients involves transparency in operations, clear commitments, and robust support systems. Our approach to providing Storage Cage solutions is centered on these principles.

Frequently Asked Questions (FAQ)

-

Q: What is the typical lifespan of a galvanized Storage Cage?

A: With proper use, hot-dip galvanized cages typically have a service life of 10-15 years or more, even in challenging environments, due to superior corrosion protection. -

Q: Can these cages be used outdoors?

A: Yes, hot-dip galvanized cages are specifically designed to withstand outdoor elements and corrosive industrial atmospheres without significant degradation. -

Q: Are your Storage Cages compatible with automated material handling systems?

A: Our standard designs adhere to common pallet dimensions, making them highly compatible. Custom solutions can be engineered for specific AGV or robotic systems. -

Q: How do I determine the right load capacity for my needs?

A: We recommend a consultation to assess the weight, distribution, and handling methods of your specific goods. Our engineers can provide detailed recommendations based on your operational data.

Lead Time & Fulfillment

We understand the importance of timely delivery for operational continuity.

- Standard Products: Typically 3-4 weeks from order confirmation, subject to current stock levels.

- Custom Solutions: 6-8 weeks, depending on complexity and quantity. This includes design finalization, material procurement, manufacturing, and quality assurance.

- Expedited Orders: Available upon request, subject to additional charges and production scheduling.

Our dedicated logistics team ensures efficient and secure delivery to your facility.

Warranty Commitments

We stand behind the quality and durability of our products. All Storage Cage units come with:

- 5-Year Structural Warranty: Covers manufacturing defects in materials and workmanship under normal operating conditions.

- 10-Year Corrosion Resistance Warranty: For hot-dip galvanized products, against red rust formation under typical atmospheric exposure, demonstrating our commitment to the longevity provided by our ISO-standard galvanization process.

Customer Support Information

Our expert support team is available to assist you from initial inquiry through post-purchase support.

- Technical Sales Support: For product inquiries, specifications, and customization requests.

- Dedicated Account Management: For ongoing orders, project coordination, and relationship management.

- After-Sales Service: For warranty claims, maintenance advice, or replacement parts.

Contact us via phone, email, or our website's contact form for prompt and professional assistance.

Conclusion

The Storage Cage stands as a cornerstone of efficient, safe, and organized material handling across a multitude of industrial sectors. Its robust construction, typically hot-dip galvanized for exceptional corrosion resistance, coupled with intelligent design features such as stackability and collapsibility, directly addresses the evolving demands of modern logistics and manufacturing. By understanding the intricate manufacturing process, recognizing the technical advantages, and leveraging customization options, businesses can implement tailored storage solutions that optimize space, reduce operational costs, and enhance overall productivity. Partnering with a reputable vendor committed to quality, transparency, and comprehensive support ensures a long-term, high-value investment in your operational infrastructure.

References

- ASTM A123/A123M-17, Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. ASTM International.

- ISO 1461:2022, Hot-dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods. International Organization for Standardization.

- Material Handling Industry (MHI). Annual Industry Report.

- Warehouse and Distribution Center (DC) Operations Survey. Logistics Management.

- European Federation of Material Handling Equipment (FEM) standards for racking and storage.

This is the last article

-

Heavy-Duty Stackable Storage Cages for Efficient Warehouse Storage

NewsAug.27,2025

-

Stainless Steel Wire Mesh: Durable & Corrosion-Resistant Rolls

NewsAug.26,2025

-

Durable Fences: Garden, Pool, Metal & Security Solutions

NewsAug.25,2025

-

Perforated Metal Mesh Sheets: Custom & Wholesale Solutions

NewsAug.24,2025

-

Durable Metal Mesh Fabric For Glass Laminated | Strength & Style

NewsAug.23,2025

-

Hexagonal Wire Mesh: Durable Galvanized & PVC Coated Rolls

NewsAug.22,2025