-

+86 15030157877

-

sales@galvanizedmetalmesh.com

فبراير . 16, 2025 10:56 Back to list

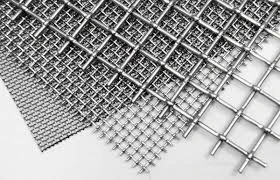

Perforated Metal Mesh

High-quality metal perforated plates have emerged as essential components across a myriad of industries, offering not only functionality but also aesthetic appeal. These plates, characterized by their precise perforations, cater to numerous applications, demonstrating both versatility and reliability. The expertise required in their manufacturing and the authority established by leading producers make them a subject of considerable interest.

Trustworthiness through Quality Assurance Trust is built through a consistent track record of delivering products that meet or exceed client expectations. High-quality metal perforated plate manufacturers adhere to stringent quality control measures throughout their production processes. Every stage—from raw material procurement to the final inspection of completed plates—undergoes rigorous checks. This commitment to quality is echoed by the warranties and post-purchase support provided by these companies, ensuring customer satisfaction and loyalty. Applications Across Industries The practical usability of metal perforated plates can be seen across multiple industries beyond construction. In the automotive sector, they are used in manufacturing heat shields and ventilation systems. In agriculture, these plates find use in grain drying processes and machinery. Additionally, the food and beverage industry leverages them for filtration purposes, showcasing their safety and reliability in contexts where hygiene is paramount. Innovative Trends As technology advances, the applications and design possibilities of metal perforated plates continue to expand. Current trends involve the integration of digital design tools that allow for more complex and aesthetically pleasing perforation patterns, perfectly aligning with modern architectural demands. Furthermore, sustainability is becoming a defining factor, with manufacturers exploring recyclable materials and energy-efficient production methods to lessen environmental impact. In conclusion, high-quality metal perforated plates represent a synergistic blend of experience, expertise, authoritativeness, and trustworthiness. Their role in enhancing efficiency and offering innovative solutions across industries underscores their value as a product. As we move forward, their continued evolution promises to further bridge the gap between practical engineering needs and creative design aspirations.

Trustworthiness through Quality Assurance Trust is built through a consistent track record of delivering products that meet or exceed client expectations. High-quality metal perforated plate manufacturers adhere to stringent quality control measures throughout their production processes. Every stage—from raw material procurement to the final inspection of completed plates—undergoes rigorous checks. This commitment to quality is echoed by the warranties and post-purchase support provided by these companies, ensuring customer satisfaction and loyalty. Applications Across Industries The practical usability of metal perforated plates can be seen across multiple industries beyond construction. In the automotive sector, they are used in manufacturing heat shields and ventilation systems. In agriculture, these plates find use in grain drying processes and machinery. Additionally, the food and beverage industry leverages them for filtration purposes, showcasing their safety and reliability in contexts where hygiene is paramount. Innovative Trends As technology advances, the applications and design possibilities of metal perforated plates continue to expand. Current trends involve the integration of digital design tools that allow for more complex and aesthetically pleasing perforation patterns, perfectly aligning with modern architectural demands. Furthermore, sustainability is becoming a defining factor, with manufacturers exploring recyclable materials and energy-efficient production methods to lessen environmental impact. In conclusion, high-quality metal perforated plates represent a synergistic blend of experience, expertise, authoritativeness, and trustworthiness. Their role in enhancing efficiency and offering innovative solutions across industries underscores their value as a product. As we move forward, their continued evolution promises to further bridge the gap between practical engineering needs and creative design aspirations.

Next:

Latest news

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

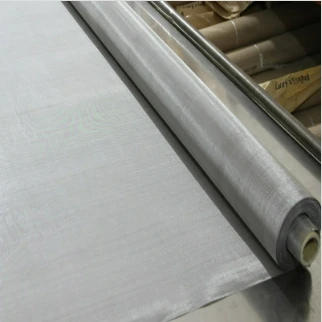

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025