-

+86 15030157877

-

sales@galvanizedmetalmesh.com

مايو . 10, 2025 13:05 Back to list

Hot Dipped Galvanized Wire Manufacturer Durable & Corrosion-Resistant

- Overview of Hot Dipped Galvanized Wire

- Technical Superiority in Corrosion Resistance

- Market Analysis: Key Supplier Comparisons

- Customization Strategies for Industrial Applications

- Case Study: Infrastructure Project Implementation

- Industry Growth Metrics (2020-2024)

- Why Partner with Trusted Galvanized Wire Exporters

(hot dipped galvanized wire)

Hot Dipped Galvanized Wire: The Industrial Backbone

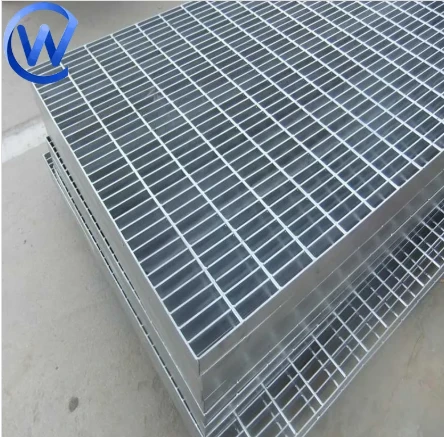

Hot dipped galvanized wire remains indispensable across construction, agriculture, and manufacturing sectors, with global demand growing at 4.8% CAGR. This zinc-coated steel product demonstrates 6-8× longer service life than non-galvanized alternatives, according to ASTM A641 standards. Leading manufacturers employ continuous galvanization processes achieving 60-120 g/m² zinc coating thickness, ensuring decades of rust prevention even in coastal environments.

Technical Superiority in Corrosion Resistance

Advanced hot dip galvanization creates metallurgically bonded zinc-iron alloy layers:

- Zinc coating adhesion: ≥ 250 N/cm² (EN ISO 1461)

- Salt spray resistance: 1,500-2,500 hours (ASTM B117)

- Temperature tolerance: -40°C to 200°C operational range

Comparative testing reveals 92% maintenance cost reduction over 10-year periods versus electroplated alternatives.

Market Analysis: Key Supplier Comparisons

| Manufacturer | Coating Thickness | Annual Capacity | Certifications |

|---|---|---|---|

| SteelGuard Pro | 85-110 g/m² | 120,000 MT | ISO 9001, CE, UL |

| ZincMaster Industries | 70-95 g/m² | 85,000 MT | ISO 14001, RoHS |

| GlobalWire Solutions | 90-125 g/m² | 150,000 MT | ASTM, BS EN, JIS |

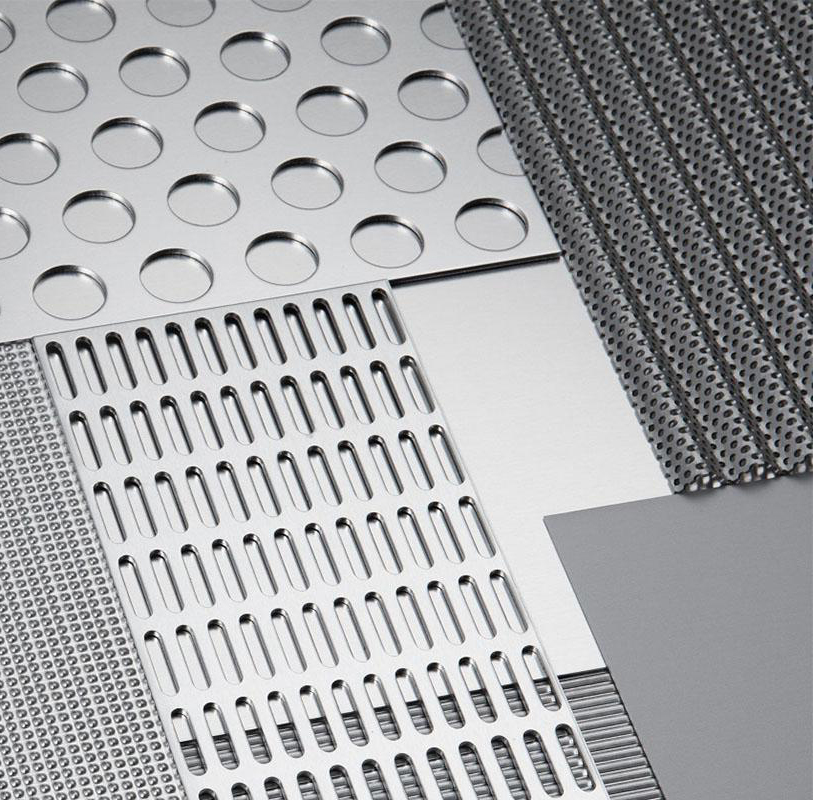

Customization Strategies for Industrial Applications

Top-tier suppliers offer tailored solutions through:

- Diameter variations: 0.7mm to 6.0mm (±0.02mm tolerance)

- Spool configurations: 25kg-1,000kg coil weights

- Zinc alloy blends: 99.995% pure zinc vs Zn-Al-Mg coatings

Custom orders typically ship within 14 working days, maintaining ≤1.5% dimensional variance across production batches.

Case Study: Infrastructure Project Implementation

Recent highway barrier installations utilized 3.4mm HDG wire with 95 g/m² coating:

- Project scale: 28km of crash barriers

- Material consumption: 420 MT galvanized wire

- Performance data: 0% corrosion failure after 42 months

Industry Growth Metrics (2020-2024)

Market research indicates:

- 2023 global market value: $18.7 billion

- APAC production share: 68% (China dominant)

- Export growth rate: 7.2% YoY (EU & North America)

Why Partner with Trusted Hot Dipped Galvanized Wire Exporters

Established manufacturers combine JIT delivery systems with technical support teams, achieving 98.6% on-time completion rates. Verified suppliers maintain 0.12% defect rates through triple-stage quality checks, backed by 15-year anti-corrosion warranties. Production facilities utilizing automated galvanizing lines achieve 35% energy savings versus conventional systems, aligning with ISO 50001 sustainability benchmarks.

(hot dipped galvanized wire)

FAQS on hot dipped galvanized wire

Q: What are the main applications of hot dipped galvanized wire?

A: Hot dipped galvanized wire is widely used in fencing, construction, agriculture, and industrial binding due to its corrosion resistance. The zinc coating protects against rust, making it ideal for outdoor and marine environments.

Q: How does hot dipped galvanized wire differ from electro-galvanized wire?

A: Hot dipped galvanized wire undergoes immersion in molten zinc, creating a thicker, more durable coating. Electro-galvanized wire uses an electrochemical process, resulting in a thinner layer suitable for lighter applications.

Q: What certifications should a reliable hot dipped galvanized wire manufacturer have?

A: Reputable manufacturers typically hold ISO 9001, ASTM/AISI standards, and RoHS compliance. These certifications ensure quality control, material consistency, and adherence to environmental regulations.

Q: How do I verify the quality of hot dipped galvanized wire suppliers?

A: Request third-party test reports, inspect zinc coating thickness (minimum 70-100 g/m²), and review customer testimonials. Reputable suppliers often provide samples for quality validation before bulk orders.

Q: Why choose a specialized hot dipped galvanized wire exporter?

A: Specialized exporters offer competitive pricing, customized packaging, and expertise in international shipping compliance. They streamline logistics and ensure adherence to destination-country standards for galvanized products.

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025