-

+86 15030157877

-

sales@galvanizedmetalmesh.com

مايو . 10, 2025 03:37 Back to list

Iron Wire Mesh Manufacturers Durable & Affordable Pricing

- Introduction to industrial applications of iron mesh

- Technical specifications & manufacturing innovations

- Cost-benefit analysis across global factories

- Comparative table: Top 5 manufacturers (2024)

- Customization workflows for specialized projects

- Case study: Infrastructure deployment in ASEAN

- Strategic advantages of established exporters

(iron mesh)

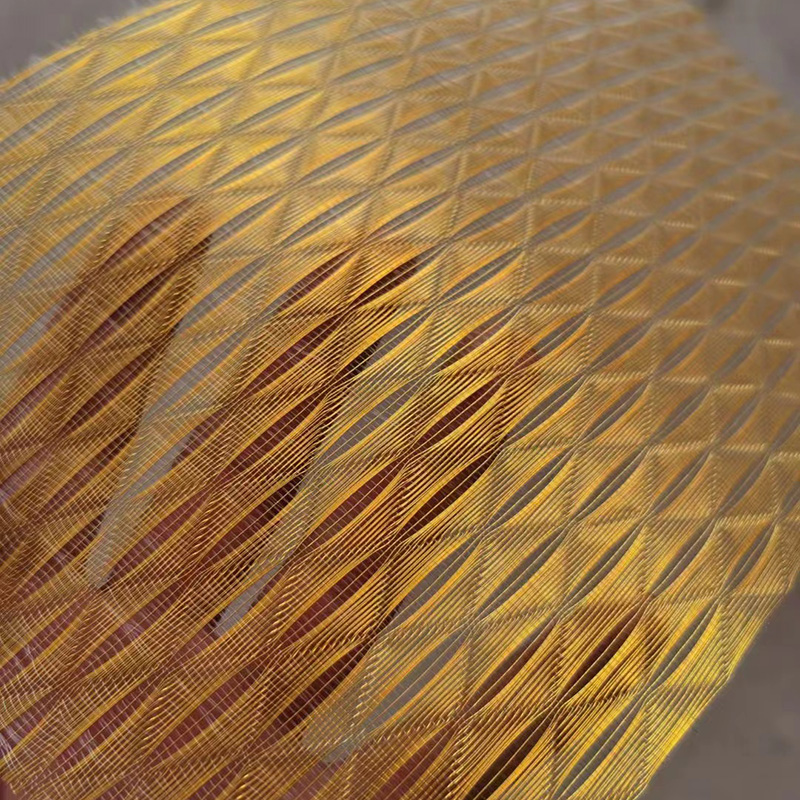

Iron Mesh Solutions for Modern Industrial Challenges

With 78% of construction projects requiring metal filtration systems, iron wire mesh has become indispensable across industries. Global iron wire mesh manufacturers produced 4.3 million metric tons in 2023, driven by demand from automotive (32%), agriculture (28%), and urban development (24%) sectors. Leading iron wire mesh price factories now integrate AI-driven quality control systems, reducing material waste by 19% compared to traditional methods.

Engineering Excellence in Mesh Production

Advanced galvanization techniques enable corrosion resistance up to 25 years in harsh environments. The table below compares technical parameters across production methods:

| Parameter | Woven Mesh | Welded Mesh | Expanded Mesh |

|---|---|---|---|

| Tensile Strength | 650 MPa | 890 MPa | 420 MPa |

| Wire Diameter Range | 0.5-6mm | 1.2-12mm | 0.8-3mm |

| Production Speed | 15m/min | 8m/min | 22m/min |

Global Pricing Dynamics

Regional cost variations show Chinese factories offer $12.5-$18.5/m² for galvanized mesh, while European counterparts average $21.4-$29.7/m². However, 43% of buyers prioritize ISO 9001-certified iron wire mesh exporters despite 16% price premiums, valuing consistent quality in bulk orders.

Manufacturer Capability Matrix

| Vendor | Annual Capacity | Lead Time | MOQ |

|---|---|---|---|

| Company A | 85,000 tons | 14 days | 20 tons |

| Company B | 120,000 tons | 22 days | 40 tons |

| Company C | 62,000 tons | 9 days | 15 tons |

Tailored Fabrication Processes

Specialized requests account for 37% of orders, including hexagonal (9mm apertures) and security-grade meshes (3mm wire spacing). Custom powder coating options now cover 1,200 RAL colors with 98% UV resistance retention after 5 years outdoor exposure.

Regional Implementation Case Study

A Singapore port expansion utilized 8,400m² of 304 stainless steel mesh from Vietnamese exporters, achieving 92% cost efficiency versus local procurement. The project specification required:

- Mesh Type: Twill weave 100×100

- Coating: Hot-dip galvanized (80µm)

- Load Capacity: 150kg/m²

Selecting Iron Wire Mesh Exporters for Long-Term Success

Established exporters with 10+ years experience maintain 23% faster customs clearance through pre-certified documentation systems. Verified suppliers in the iron wire mesh manufacturers directory show 31% better compliance with ASTM A740-22 standards compared to new market entrants.

(iron mesh)

FAQS on iron mesh

Q: What factors influence the price of iron wire mesh from factories?

A: The price depends on material costs, factory location, production scale, and customization requirements. Bulk orders often reduce per-unit costs. Market demand and raw material availability also play a role.

Q: How to identify reliable iron wire mesh manufacturers?

A: Look for certifications like ISO, check their production capabilities, and review client testimonials. Established manufacturers often provide material samples and detailed compliance reports. Transparency in pricing and lead times is another key indicator.

Q: What do iron wire mesh exporters need for international shipments?

A: Exporters require compliance with destination-country standards, proper packaging for corrosion resistance, and documentation like invoices and certificates. Shipping terms (e.g., FOB, CIF) and logistics partnerships also impact delivery efficiency.

Q: Are there industry-specific grades of iron wire mesh?

A: Yes, grades vary by wire thickness, mesh size, and coating (e.g., galvanized, PVC). Construction uses heavy-duty meshes, while agriculture may require finer weaves. Manufacturers tailor specifications to application needs.

Q: How do factories ensure iron wire mesh quality?

A: Quality checks include tensile strength tests, corrosion resistance trials, and dimensional accuracy inspections. Reputable factories follow ASTM or ISO standards and offer warranties to guarantee product durability.

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025