-

+86 15030157877

-

sales@galvanizedmetalmesh.com

أغسطس . 13, 2025 01:20 Back to list

Premium Rib Lath for Durable Stucco & Plaster Systems

The Foundation of Form and Function: Understanding Rib Lath in Modern Construction

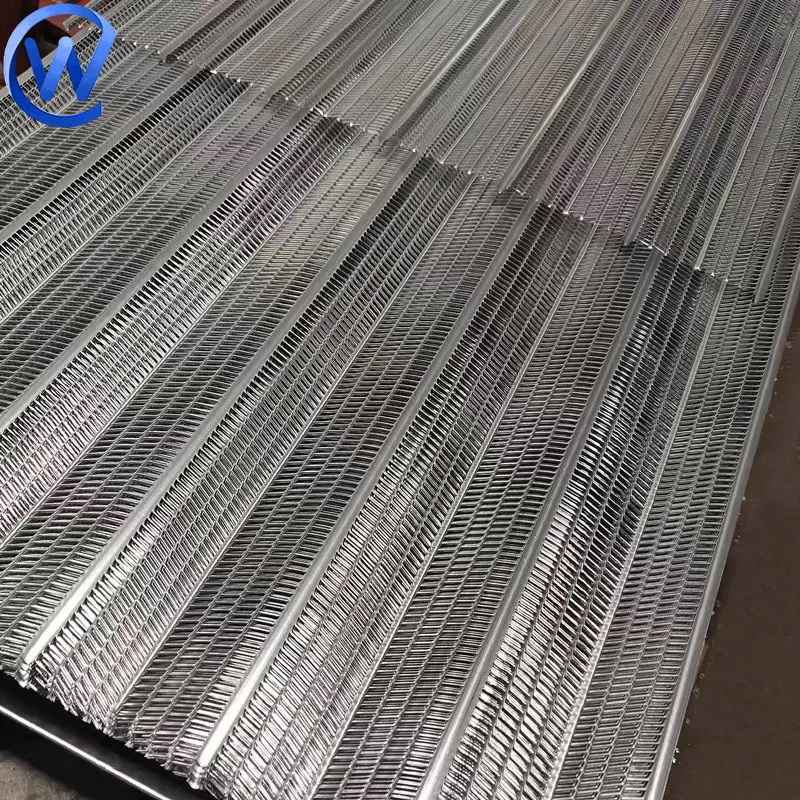

In the intricate world of construction, the integrity and durability of a structure often hinge on foundational elements that are unseen yet critical. Among these, Rib Lath stands out as an indispensable component, primarily serving as a robust plaster and stucco base. This expanded metal mesh, characterized by its integral longitudinal ribs, provides exceptional rigidity and an optimal key for applied finishes. Its unique design not only enhances bonding properties but also significantly contributes to the overall structural stability and fire resistance of walls, ceilings, and other architectural features. From intricate ceiling designs to robust exterior facade systems, the adaptability and performance of Rib Lath make it a cornerstone material for architects, contractors, and building developers seeking long-term reliability and superior surface finishes in diverse construction projects globally. Its strategic application is vital for achieving both aesthetic excellence and engineering resilience.

The industry trends indicate a growing demand for materials that offer both cost-efficiency and enhanced performance, particularly in terms of adhesion and crack prevention. Rib Lath perfectly aligns with these trends by offering a highly effective mechanical bond for plaster and stucco, thereby minimizing the common issues of delamination and surface cracking. This translates into reduced maintenance costs and extended service life for buildings, a significant advantage for B2B clients focused on long-term asset value. Moreover, its lightweight nature combined with high strength facilitates easier handling and quicker installation, contributing to accelerated project timelines and reduced labor costs—critical factors in today's competitive construction landscape. Its proven track record across various climates and building types solidifies its position as a preferred choice for professionals.

Precision Engineering: The Manufacturing Process of Rib Lath

The production of high-quality Rib Lath is a sophisticated industrial process, beginning with carefully selected raw materials, typically galvanized steel sheets or cold-rolled steel coils. The choice of material is crucial, with galvanized steel offering superior corrosion resistance, particularly vital for exterior applications or humid environments, extending the product's lifespan significantly. The manufacturing sequence involves precision slitting, where sheets are cut into specific patterns. This is followed by the expansion process, where the slitted material is stretched, creating the characteristic diamond-shaped openings. Concurrently, specialized machinery forms the integral V-shaped ribs, which are crucial for enhancing the lath's stiffness and providing the essential plaster key. This cold-forming process ensures consistent mesh patterns and uniform rib heights, critical for predictable performance.

Quality control is paramount throughout the manufacturing journey. Each batch of Rib Lath undergoes rigorous inspection to meet international standards such as ASTM C847 (Standard Specification for Metals Lath) and ISO compliance. Key parameters checked include mesh opening size, rib height, material thickness (gauge), and overall sheet dimensions. Adherence to these standards ensures uniformity, structural integrity, and optimal performance in various applications. For instance, a consistent rib height, often ranging from 3/8 inch (9.5mm) to 3/4 inch (19mm) for standard profiles, guarantees adequate keying for plaster or stucco. The result is a robust, reliable product with an expected service life exceeding 50 years when properly installed and maintained, particularly in less aggressive environments due to its inherent corrosion-resistant properties when galvanized. This stringent process ensures that every sheet of Rib Lath contributes to the longevity and stability of the final structure.

Technical Parameters & Performance Metrics of Rib Lath

The effectiveness of Rib Lath in construction is underpinned by a precise set of technical specifications that define its physical and performance characteristics. These parameters are critical for engineers and contractors to select the appropriate lath for specific project requirements, ensuring structural integrity and optimal finish adhesion. Below is a comprehensive table outlining typical specifications for standard Rib Lath products, reflecting common industry offerings and performance benchmarks.

Typical Rib Lath Specifications

| Parameter | Description | Common Range/Value | Standard Compliance |

|---|---|---|---|

| Material Type | Galvanized steel, hot-dipped or electro-galvanized. | G60 (ASTM A653) or equivalent. | ASTM A653/A653M |

| Gauge (Thickness) | Thickness of the sheet metal before expansion. | 26 Gauge (0.45mm) to 20 Gauge (0.91mm) | ASTM C847 |

| Rib Height | Height of the V-shaped integral ribs. | 3/8" (9.5mm), 1/2" (12.7mm), 3/4" (19mm) | ASTM C847 |

| Sheet Weight | Weight per square yard or square meter. | 2.75 lb/yd², 3.4 lb/yd², 4.0 lb/yd² | ASTM C847 |

| Sheet Dimensions | Standard width and length of the sheets. | 27" x 96" (0.68m x 2.44m) or 24" x 96" | Industry Standard |

| Openings per Sq. Inch | Number of diamond openings providing plaster key. | Variable, depends on mesh pattern. | ASTM C847 |

| Fire Rating (System Dependent) | Contribution to fire resistance when part of a system. | Up to 2-hour rating with appropriate plaster thickness. | UL, ASTM E119 |

The strategic selection of these parameters allows for optimal performance in diverse environments. For instance, a heavier gauge Rib Lath (e.g., 20 gauge) is often preferred for applications requiring higher structural rigidity, such as suspended ceilings or demanding exterior stucco systems. Conversely, lighter gauges (e.g., 26 gauge) are suitable for general interior plastering where weight is a consideration. The galvanization level directly correlates with the lath's anti-corrosion properties, which is paramount for external walls or areas exposed to moisture. By understanding and leveraging these specifications, B2B stakeholders can confidently specify Rib Lath products that align precisely with project requirements and long-term performance objectives, ensuring superior outcomes in terms of durability, safety, and aesthetic finish.

Versatile Applications: Where Rib Lath Excels

The inherent adaptability of Rib Lath makes it a favored material across a broad spectrum of construction applications, from residential to large-scale commercial and industrial projects. Its primary function is to provide a solid, stable base for plaster, stucco, and fireproofing materials. In interior spaces, it is extensively used for creating ceilings, partitions, and decorative elements. For instance, in suspended ceiling systems, Rib Lath offers lightweight support and a uniform surface for plaster, contributing to improved acoustics and fire ratings. Its rigidity allows for longer spans between supports compared to flat lath, optimizing material usage and installation time. For partition walls, it ensures a durable, crack-resistant surface that can withstand daily wear and tear.

In exterior applications, Rib Lath is crucial for stucco and EIFS (Exterior Insulation Finishing Systems). Its robust profile ensures excellent keying for multiple coats of stucco, providing a monolithic, weather-resistant facade. This is particularly vital in regions prone to extreme weather conditions, where the material's ability to resist cracking and provide robust adhesion directly impacts the longevity of the building envelope. Moreover, Rib Lath finds significant use in fireproofing structural steel members. When wrapped around steel beams and columns and then coated with fire-resistant plaster or vermiculite, it forms a protective barrier that significantly enhances the building's fire safety rating, crucial for meeting stringent building codes. Its superior stiffness compared to standard diamond mesh lath makes it easier to handle and attach to various substrates, leading to faster and more efficient project completion.

Beyond conventional uses, Rib Lath is increasingly adopted in specialized projects such as sound insulation constructions, curved surface applications, and even in some formwork designs where a rough, keying surface is required for subsequent concrete pours. Its ability to conform to gentle curves while maintaining structural integrity allows for innovative architectural designs. The material's inherent strength and design minimize waste during installation, promoting sustainable building practices. For contractors, the ease of cutting and forming Rib Lath translates into significant labor savings and increased productivity on site, making it an economically viable and high-performing solution for modern construction challenges.

Strategic Advantages & Value Proposition of Rib Lath

The adoption of Rib Lath offers a compelling value proposition for B2B clients, translating into tangible benefits across project lifecycle stages. Its primary technical advantage lies in its superior bonding capabilities. The integral ribs create a strong mechanical key for plaster or stucco, significantly reducing the risk of delamination and cracking, common issues that can lead to costly repairs and diminished aesthetic appeal over time. This enhanced adhesion ensures a robust, long-lasting surface that maintains its integrity even under varying environmental conditions. Furthermore, the inherent rigidity provided by the ribs allows for wider spacing of structural supports, reducing the need for excessive framing and consequently cutting down on material costs and installation time, a direct economic benefit.

Beyond its mechanical properties, the corrosion resistance offered by galvanized Rib Lath is a critical advantage, particularly for exterior applications. The zinc coating acts as a sacrificial layer, protecting the steel core from rust and extending the lath's operational lifespan, thereby enhancing the overall durability of the structure. This translates into lower maintenance overheads and a higher return on investment for building owners. From an energy efficiency perspective, when used as part of an EIFS, Rib Lath contributes to better insulation performance, helping to create more thermally efficient building envelopes. This not only aids in achieving green building certifications but also results in long-term energy savings for the occupants, aligning with modern sustainable construction goals.

Considering total cost of ownership, the initial investment in high-quality Rib Lath is justified by its long-term benefits in terms of reduced repairs, extended facade life, and improved building performance. For B2B decision-makers, this translates into reliable project delivery, enhanced reputation, and significant lifecycle cost savings. Our commitment to adhering to stringent industry standards like ASTM C847 ensures that every sheet of Rib Lath delivered meets the highest benchmarks for quality and performance, providing peace of mind and building trust with our partners. We ensure that our products contribute directly to building robust, enduring, and high-performance structures.

Ensuring Quality & Reliability: Compliance and Certification

For B2B clients, the assurance of quality and adherence to industry standards are paramount when sourcing construction materials. Our Rib Lath products are manufactured under strict quality management systems, often compliant with ISO 9001, ensuring consistency from raw material procurement to final product delivery. We rigorously adhere to established national and international standards, most notably ASTM C847 (Standard Specification for Metal Lath) and ASTM A653/A653M (for galvanized steel sheet). These certifications are not merely badges; they represent a commitment to precise manufacturing tolerances, material integrity, and predictable performance on site. Regular third-party audits and internal testing protocols ensure that every batch of Rib Lath consistently meets or exceeds these benchmarks.

Our long-standing service in the industry, coupled with collaborations with reputable construction firms and material testing laboratories, further reinforces our authoritative position. We provide comprehensive test data sheets upon request, detailing mechanical properties, galvanization thickness, and fire performance characteristics where applicable (as part of a system assembly). For instance, specific fire-rated wall assemblies incorporating Rib Lath may be tested and listed by organizations like Underwriters Laboratories (UL) or Factory Mutual (FM Global), providing objective proof of their safety contributions. This transparency and commitment to verifiable quality metrics build invaluable trust with our partners, ensuring that every project built with our Rib Lath is founded on reliable, high-performing materials.

Tailored Solutions & Collaborative Partnerships

Recognizing that every construction project possesses unique demands, we specialize in offering customized Rib Lath solutions designed to meet specific architectural and engineering requirements. While standard specifications cater to a broad range of applications, particular projects might necessitate variations in material gauge, rib height, sheet dimensions, or galvanization levels. Our technical team works in close collaboration with clients, leveraging years of industry experience to provide expert consultation and develop bespoke manufacturing plans. Whether it's a large-scale infrastructure project requiring unique panel sizes for efficiency or a heritage restoration demanding specific material properties, our flexible production capabilities ensure precise fulfillment.

This collaborative approach extends to logistical planning, where we ensure efficient delivery schedules tailored to project timelines. Our robust supply chain management and strategic partnerships with freight forwarders minimize lead times and ensure on-time delivery, a critical factor for maintaining project momentum. We understand that in the B2B sector, reliable partnership is as important as product quality. By offering comprehensive support from initial consultation to post-delivery assistance, we aim to be more than just a supplier; we strive to be a trusted extension of our clients' project teams, contributing to their success with every sheet of Rib Lath.

Navigating Your Investment: FAQs, Delivery & Support

Frequently Asked Questions (FAQs)

-

Q: What is the typical lead time for an order of Rib Lath?

A: Standard orders for Rib Lath typically have a lead time of 7-14 business days, depending on quantity and current production schedules. Customized orders may require additional time for fabrication and quality checks. We recommend contacting our sales team for precise timelines based on your specific needs. -

Q: Is Rib Lath suitable for exterior applications in harsh climates?

A: Yes, particularly our galvanized Rib Lath. The zinc coating provides excellent corrosion resistance, making it highly suitable for exterior stucco and plaster applications in diverse climatic conditions, including humid or coastal environments. -

Q: What kind of warranty do you offer on Rib Lath products?

A: We provide a product warranty against manufacturing defects, typically covering a period of 10 years, ensuring that our Rib Lath meets specified material and quality standards. Detailed warranty terms are available upon request. -

Q: How does Rib Lath contribute to fire safety?

A: When installed as part of a fire-rated assembly with appropriate plaster or fireproofing materials, Rib Lath significantly enhances the fire resistance of structural elements, helping to achieve specified hourly fire ratings as per building codes like ASTM E119.

Delivery & Customer Support

Our streamlined logistics ensure reliable delivery of Rib Lath to your project site. We operate with flexible delivery schedules to accommodate varying project phases and inventory needs, offering both standard and expedited shipping options. Our commitment extends beyond product delivery to comprehensive customer support. Our dedicated technical support team is available to assist with product selection, installation guidance, and any post-purchase inquiries. We believe that robust support is integral to building long-term, trustworthy relationships with our B2B partners, ensuring successful project outcomes and client satisfaction.

Concluding Insights: The Enduring Value of Rib Lath

The continuous evolution of construction demands materials that offer a blend of high performance, durability, and cost-effectiveness. Rib Lath, with its meticulously engineered design and superior material properties, consistently meets these criteria. Its role as an essential base for plaster and stucco is foundational, ensuring long-term structural integrity and aesthetic quality across a diverse range of applications. From enhancing fire resistance to providing unparalleled bonding for finishes, the advantages of integrating Rib Lath into building designs are clear and compelling. Choosing a reliable manufacturer that adheres to stringent quality standards and offers tailored solutions further amplifies these benefits, guaranteeing a valuable investment for any construction project.

References

- American Society for Testing and Materials (ASTM). ASTM C847-19: Standard Specification for Metal Lath. West Conshohocken, PA: ASTM International, 2019.

- American Society for Testing and Materials (ASTM). ASTM A653/A653M-20: Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process. West Conshohocken, PA: ASTM International, 2020.

- International Organization for Standardization (ISO). ISO 9001:2015: Quality management systems—Requirements. Geneva, Switzerland: ISO, 2015.

- National Research Council Canada. The National Building Code of Canada 2015. Ottawa, ON: NRC Publications, 2015.

- Underwriters Laboratories (UL). UL 263: Standard for Fire Tests of Building Construction and Materials. Northbrook, IL: UL, 2019.

This is the last article

-

Premium Rib Lath for Durable Stucco & Plaster Systems

NewsAug.13,2025

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025