-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ديسمبر . 11, 2024 09:40 Back to list

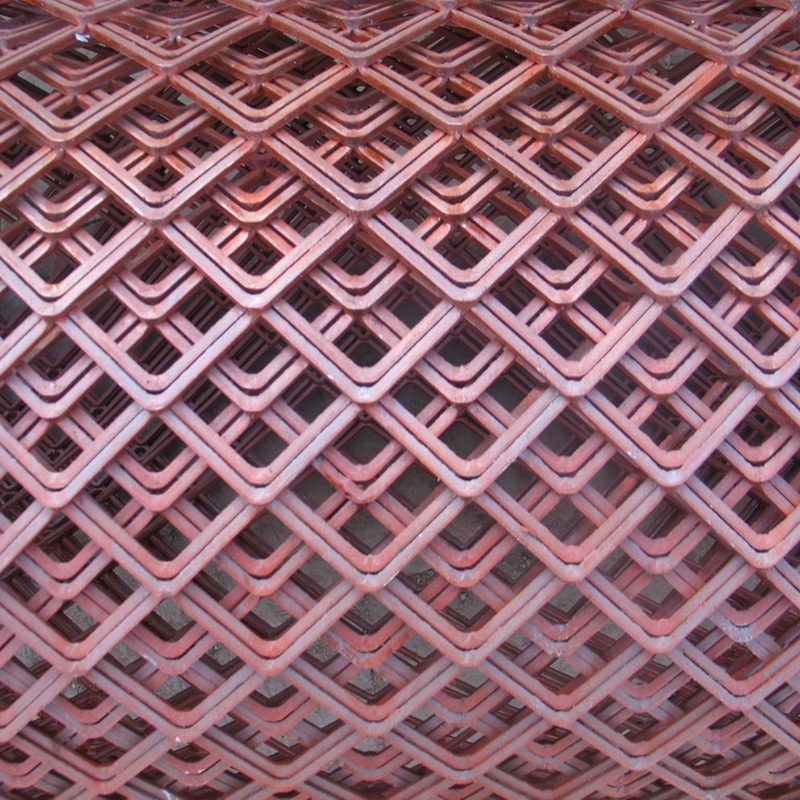

PVC-Coated Wire Mesh Manufacturers and Suppliers for Various Applications

The Rise of PVC Coated Wire Mesh Factories

In recent years, the demand for durable and versatile fencing and mesh solutions has skyrocketed, leading to a notable rise in the establishment of PVC coated wire mesh factories. These facilities specialize in producing high-quality wire mesh products that are not only functional but also aesthetically pleasing, making them suitable for a wide range of applications.

What is PVC Coated Wire Mesh?

PVC coated wire mesh consists of a base metal wire, typically made of galvanized steel, which is coated with a layer of polyvinyl chloride (PVC). This coating serves multiple purposes it enhances the wire's resistance to corrosion, increases its lifespan, and provides a variety of colors and finishes that can match different environments. The result is a robust product that combines the strength of metal with the protective properties of PVC.

Applications of PVC Coated Wire Mesh

The versatility of PVC coated wire mesh makes it suitable for numerous applications. One of its primary uses is in the construction of fencing for both residential and commercial properties. Homeowners and businesses alike appreciate the combination of security and aesthetic appeal this product offers. Additionally, it is commonly used in agricultural settings for livestock enclosures, gardens, and crop protection. The coated wire mesh allows for adequate air circulation while preventing animals from escaping or wild animals from entering.

In industrial contexts, PVC coated wire mesh is utilized in various filtration systems, as it can effectively separate materials based on size while resisting environmental wear and tear. The construction industry also benefits from its use in reinforcing structures, as the coated mesh adds a level of durability that is essential for safety and longevity.

Benefits of PVC Coated Wire Mesh

The popularity of PVC coated wire mesh can be attributed to several key benefits. First and foremost, the PVC coating provides exceptional resistance to rust and corrosion, extending the life of the product significantly compared to uncoated alternatives. This durability translates into lower maintenance costs and fewer replacements over time.

pvc coated wire mesh factories

Furthermore, the variety of colors available allows customers to choose a product that complements their specific design needs. Unlike traditional metal mesh, which can be an eyesore, PVC coated options can blend seamlessly into their environment, enhancing overall aesthetic appeal.

Another advantage is the ease of installation

. PVC coated wire mesh is lightweight yet strong, making it manageable for construction and fencing teams. Additionally, thanks to its flexibility, it can be tailored to fit specific dimensions, making it suitable for unique project requirements.The Growth of PVC Coated Wire Mesh Factories

As the demand for PVC coated wire mesh has grown, so too have the factories dedicated to its production. Many of these facilities have adopted modern manufacturing techniques that improve efficiency and product quality. Automation and advanced machinery allow for higher output rates while maintaining strict quality control standards.

Moreover, the global push towards sustainable practices has encouraged manufacturers to explore eco-friendly options in their production processes. Some factories are investing in recyclable materials and energy-efficient systems, contributing to a more sustainable future.

In addition to local markets, many PVC coated wire mesh factories are beginning to export their products internationally. This expansion is driven by the growing recognition of the benefits of PVC coated wire mesh in various industries across the globe.

Conclusion

The emergence of PVC coated wire mesh factories marks a significant evolution in fencing and mesh solutions. With their blend of durability, aesthetic appeal, and versatility, these products are making significant strides in numerous sectors. As demand continues to rise, these factories are poised to play a critical role in meeting the needs of an increasingly diverse customer base, all while maintaining a commitment to quality and sustainability. This trend not only addresses immediate market demands but also contributes to a more innovative and environmentally conscious future in manufacturing.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025