-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ديسمبر . 28, 2024 10:06 Back to list

stainless steel bird cage wire mesh factories

A Comprehensive Overview of Stainless Steel Bird Cage Wire Mesh Factories

In recent years, the demand for high-quality stainless steel bird cage wire mesh has surged due to the growing interest in pet birds and the increasing need for durable, safe, and aesthetically pleasing enclosures. As a result, more factories are being established across the globe to produce this essential material. This article provides an in-depth look at stainless steel bird cage wire mesh factories, focusing on their production processes, advantages, and the role they play in the pet industry.

Understanding Stainless Steel Bird Cage Wire Mesh

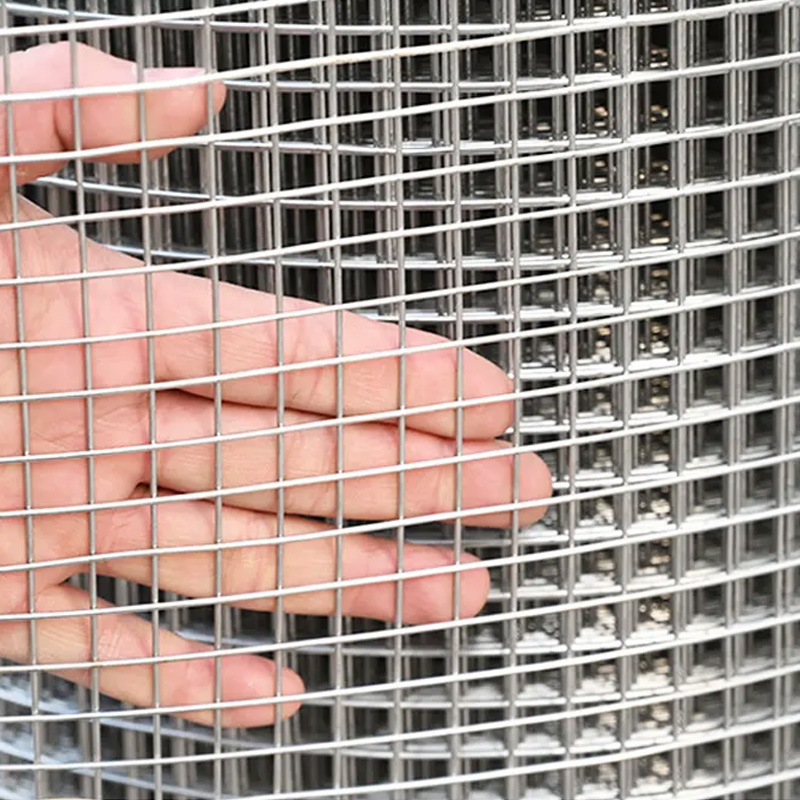

Stainless steel wire mesh is made from stainless steel alloy, renowned for its strength, durability, and resistance to rust and corrosion. This makes it an ideal choice for bird cages, as it can withstand varying environmental conditions while ensuring the safety of the birds inside. The wire mesh is woven into various patterns, allowing for different designs and functionalities in bird cage construction.

The Manufacturing Process

The production of stainless steel bird cage wire mesh typically involves several key steps

1. Material Selection High-quality stainless steel, often type 304 or 316, is chosen for its excellent resistance to corrosion. The selected material is then subjected to quality control checks to ensure it meets industry standards.

2. Wire Drawing The stainless steel is drawn into wire of specific diameters. This process involves reducing the diameter of the wire by pulling it through a series of dies. The resulting wire is strong yet flexible, allowing for easy manipulation during the weaving process.

3. Weaving The drawn wire is then woven into various mesh patterns, such as plain weave, twill weave, or decorative weave. Each pattern has its unique appearance and structural characteristics, catering to different consumer preferences and requirements.

4. Finishing Treatments After weaving, the wire mesh undergoes various finishing treatments. This may include polishing to enhance appearance, passivation to improve corrosion resistance, and an optional protective coating for added durability.

5. Quality Control Throughout the production process, quality control measures are implemented to ensure the final product meets required specifications. This may include testing for strength, porosity, and visual inspection for imperfections.

6. Packaging and Distribution Once the wire mesh is produced and passes quality checks, it is packaged for distribution. Factories often work with a network of suppliers and retailers to ensure that their products reach customers efficiently.

stainless steel bird cage wire mesh factories

Advantages of Stainless Steel Wire Mesh

Stainless steel bird cage wire mesh offers numerous advantages over other materials, making it a preferred choice among manufacturers and pet owners alike

- Durability Stainless steel is incredibly durable, ensuring that cages can withstand the test of time and resist damage from weather, pests, and physical stress.

- Corrosion Resistance Unlike other metals, stainless steel does not rust, making it ideal for both indoor and outdoor environments.

- Safety The non-toxic nature of stainless steel ensures that there are no harmful chemicals leaching into the birds' confined space, promoting their health and well-being.

- Aesthetic Appeal Stainless steel provides a sleek, modern look that can enhance the overall design of bird enclosures.

- Easy Maintenance The smooth surface of stainless steel allows for easy cleaning, a critical factor for maintaining hygiene in bird cages.

The Role of Factories in the Pet Industry

Stainless steel bird cage wire mesh factories play a crucial role in the pet industry by supplying essential materials for the production of bird cages, aviaries, and related accessories. By meeting the growing demands for quality products, these factories ensure that pet owners have access to safe and durable solutions for their feathered companions.

Moreover, with advancements in technology, many manufacturers are exploring more efficient production methods and sustainable practices. This shift not only benefits the environment but also caters to a market increasingly concerned with sustainability.

Conclusion

Stainless steel bird cage wire mesh factories are vital to the thriving pet industry, providing high-quality, durable materials for bird enclosures. Through meticulous manufacturing processes and an understanding of market demands, these factories are well-positioned to meet the needs of modern pet owners, ensuring the safety and comfort of their beloved avian pets. As the industry evolves, these factories will continue to innovate, contributing to the overall growth and sustainability of the pet care market.

-

Chicken Wire Fence Suppliers Durable & Affordable Poultry Solutions

NewsMay.19,2025

-

Mesh Screen Panels High-Quality Exporter & Manufacturer Solutions

NewsMay.19,2025

-

3D Panel Fence for Cattle Farms Durable & Customizable Solutions

NewsMay.19,2025

-

Barbed Wire Mesh High-Security Razor Fencing Solutions by Experts

NewsMay.18,2025

-

Durable Deer Netting Solutions Reliable Manufacturer & Supplier

NewsMay.18,2025

-

Durable 1x1 Welded Wire Mesh Panels Custom & Export Solutions

NewsMay.18,2025