-

+86 15030157877

-

sales@galvanizedmetalmesh.com

أغسطس . 10, 2024 10:40 Back to list

Top Suppliers for Quality Aluminum Perforated Sheets for Various Applications and Industries

The Rise of Aluminum Perforated Sheet Suppliers

In the modern manufacturing landscape, aluminum perforated sheets have gained significant traction due to their versatility and aesthetic appeal. These sheets are extensively used across various industries, including construction, architecture, automotive, and consumer goods. With the rising demand for lightweight, durable materials, many suppliers have emerged to meet the needs of both large-scale manufacturers and smaller businesses.

Understanding Aluminum Perforated Sheets

Aluminum perforated sheets are made from aluminum alloy sheets that have been punched with holes of various sizes and patterns. This process not only enhances their aesthetic characteristics but also improves functionality by making them lighter and more flexible. The perforations allow for ventilation, reduce weight without compromising strength, and provide unique design elements that can enhance a product's visual appeal.

The Versatile Applications

The versatility of aluminum perforated sheets is evident in their wide-ranging applications. In architecture, they are used for facades, ceilings, and decorative elements, providing both light and privacy. In the automotive industry, they serve critical roles in the formation of parts that require both strength and reduced weight. Additionally, they are commonly utilized in filtration systems, HVAC systems, and acoustic panels, making them integral in various engineering projects.

Why Choose Aluminum?

Aluminum is favored for its lightweight nature, resistance to corrosion, and recyclability. These characteristics make aluminum perforated sheets an eco-friendly choice that aligns with the growing emphasis on sustainability in manufacturing. Furthermore, aluminum can be easily shaped and fabricated, providing suppliers the flexibility to cater to custom designs and specifications based on clients’ needs.

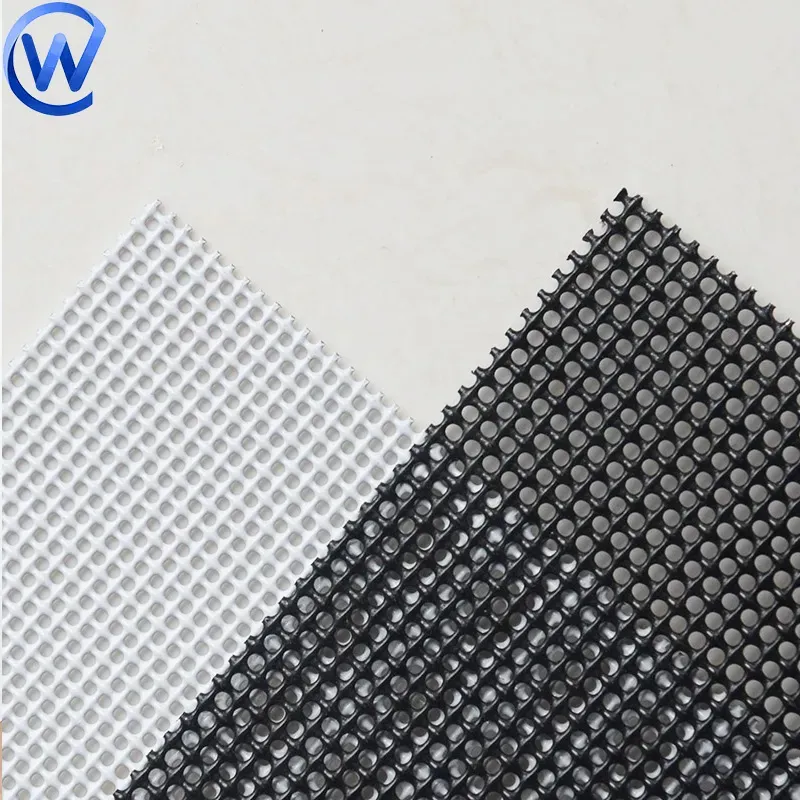

aluminum perforated sheet suppliers

Selecting the Right Supplier

Choosing the right aluminum perforated sheet supplier is crucial. Factors to consider include the range of products offered, the ability to customize, manufacturing processes, delivery timelines, and pricing. Also important is the supplier's reputation, which can be gauged through customer reviews and industry accolades. Leading suppliers often provide extensive catalogs, showcasing various hole sizes, patterns, and sheet thicknesses, allowing customers to make informed choices.

The Digital Transformation of Suppliers

The advent of e-commerce has transformed how aluminum perforated sheet suppliers operate. Many suppliers now offer online platforms where customers can browse products, request quotes, and place orders with ease. This digital approach not only streamlines the purchasing process but also allows customers access to a wider range of products from suppliers across different geographical locations.

Industry Trends and Future Outlook

As industries continue to evolve, aluminum perforated sheets are anticipated to remain in vogue. The push for lightweight yet durable materials will propel further innovations in this area. Suppliers are also likely to explore more sustainable production methods, further enhancing the eco-friendliness of aluminum products.

In conclusion, aluminum perforated sheet suppliers play a pivotal role in meeting the growing demands of various industries. With their versatility, aesthetic appeal, and sustainability attributes, aluminum perforated sheets are set to become even more prevalent in the future. Choosing the right supplier is essential to leverage these benefits effectively. As the market continues to expand, staying informed about industry trends and innovations will be crucial for businesses looking to utilize aluminum perforated sheets in their projects. Whether for architectural designs, automotive parts, or filtration systems, these materials are shaping the future of manufacturing across the globe.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025