-

+86 15030157877

-

sales@galvanizedmetalmesh.com

نوفمبر . 02, 2024 18:29 Back to list

welded mesh for concrete manufacturer

The Importance of Welded Mesh in Concrete Construction

Welded mesh has become a crucial component in the construction industry, particularly for concrete reinforcement. As a manufacturer of welded mesh, it is vital to understand its significance, applications, and advantages, as well as the manufacturing processes involved in producing high-quality products for concrete structures.

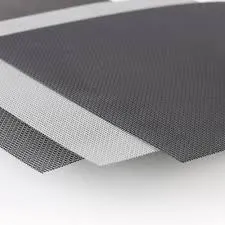

Understanding Welded Mesh

Welded mesh, often referred to as welded wire fabric, consists of cross-wires and longitudinal wires that are electrically welded together at their intersections. This configuration provides excellent structural integrity and durability. The mesh is produced in various sizes and spacing, tailored to meet specific engineering requirements. Typically, it is available in rolls or sheets, making it versatile for different types of construction projects.

Applications in Concrete Reinforcement

The primary application of welded mesh is in the reinforcement of concrete. Concrete, while strong in compression, is weak in tension. Therefore, the addition of welded mesh enhances its tensile strength, preventing cracks and ensuring a longer lifespan for the structure. It finds its application in various constructions, including

1. Slabs and Floors Welded mesh is widely used in the reinforcement of concrete slabs and floors, providing a stable surface that withstands heavy loads and reduces the chances of cracking. 2. Walls and Foundations In the construction of walls and foundations, welded mesh acts as a reliable support system, enhancing structural integrity and enabling buildings to resist environmental stresses. 3. Roads and Bridges The use of welded mesh in roadways and bridges contributes to safer and more resilient transport infrastructure, particularly beneficial in high-load and high-traffic situations.

welded mesh for concrete manufacturer

Advantages of Welded Mesh

Manufacturers highlight several advantages of using welded mesh in concrete construction. Some of these include

1. Cost-Effectiveness Using welded mesh in concrete applications can often be more economical than traditional reinforcement methods. Its mass production allows for competitive pricing and reduces labor costs during installation. 2. Consistent Quality As a manufactured product, welded mesh offers consistency in gauge, spacing, and strength, which minimizes variations and improves overall quality in concrete applications. 3. Reduced Cracking By dispersing tension across the concrete surface, welded mesh significantly reduces the likelihood of cracking, leading to lower maintenance costs and increased durability. 4. Ease of Handling and Installation Welded mesh is lightweight and easy to handle, which simplifies the installation process. This ease of use is especially beneficial in large-scale construction projects.

Manufacturing Process

The manufacturing process of welded mesh involves several key steps

1. Wire Production High-quality steel wire is produced in various diameters to meet specific project requirements. 2. Mesh Production Wires are arranged in a grid pattern and welded together at their intersections using electric resistance welding. 3. Finishing The finished mesh is then cut, rolled, or packaged according to customer specifications.

In conclusion, welded mesh is an integral part of modern concrete construction, offering reliable reinforcement solutions that enhance durability and structural integrity. As a manufacturer, understanding the applications, advantages, and manufacturing processes involved is essential to meeting the needs of the construction industry effectively. With the ever-evolving demands of construction projects, the role of welded mesh will continue to grow, making it a key element in achieving safe and robust structural designs.

-

Stainless Steel Angle Factories: Premium Quality & Custom Solutions

NewsAug.28,2025

-

Heavy-Duty Stackable Storage Cages for Efficient Warehouse Storage

NewsAug.27,2025

-

Stainless Steel Wire Mesh: Durable & Corrosion-Resistant Rolls

NewsAug.26,2025

-

Durable Fences: Garden, Pool, Metal & Security Solutions

NewsAug.25,2025

-

Perforated Metal Mesh Sheets: Custom & Wholesale Solutions

NewsAug.24,2025

-

Durable Metal Mesh Fabric For Glass Laminated | Strength & Style

NewsAug.23,2025