-

+86 15030157877

-

sales@galvanizedmetalmesh.com

نوفمبر . 23, 2024 17:54 Back to list

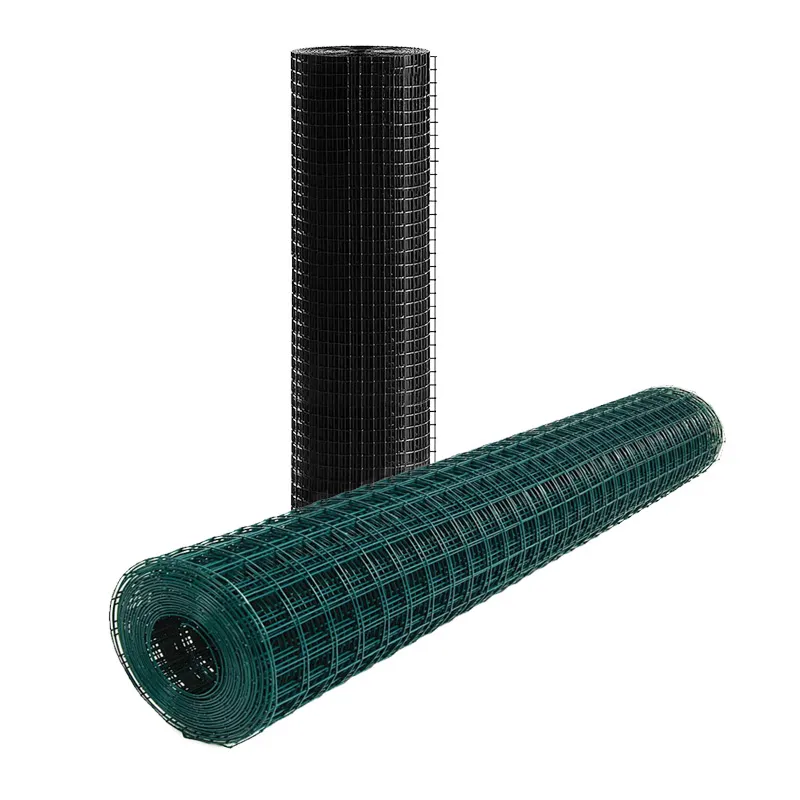

Wire mesh panel production experts for superior quality fencing solutions and industrial applications

The Importance of Selecting the Right Wire Mesh Panel Manufacturer

When it comes to industrial solutions, wire mesh panels play a crucial role in various applications, such as fencing, separation, and security. Given their versatility, the demand for these structures continues to grow across numerous sectors, including construction, agriculture, and manufacturing. However, the quality of wire mesh panels is inherently linked to the manufacturer you choose. This article highlights the significance of selecting the right wire mesh panel manufacturer and the factors to consider in this decision-making process.

Understanding Wire Mesh Panels

Wire mesh panels are made from interwoven wires, usually crafted from materials such as steel, stainless steel, or aluminum. These panels come in various configurations, including welded, woven, or expanded types, each serving different purposes. Their common applications range from agricultural fencing and animal enclosures to architectural designs and industrial partitions. The efficacy and longevity of wire mesh panels largely depend on the manufacturing process and materials used.

Quality Assurance

One of the foremost reasons to thoroughly vet wire mesh panel manufacturers is to ensure that you receive high-quality products. Manufacturers with a good reputation invest in quality assurance processes to guarantee that their products meet industry standards. This includes rigorous testing of materials and finished products to ensure they withstand environmental factors, stress, and wear over time.

When evaluating a manufacturer, inquire about their quality control measures. Do they have certifications such as ISO 9001, which indicates a commitment to quality management systems? Read customer reviews and feedback that highlight experiences regarding product quality and durability. A reputable manufacturer should be willing to share this information with potential clients.

Customization Options

Another vital factor to consider is the customization options available. Different projects require different specifications, and many manufacturers offer tailored solutions that can meet unique needs. This might include variations in wire gauge, panel size, coating options, and additional features like UV resistance or corrosion-proofing.

A capable wire mesh panel manufacturer should be open to discussing your specific requirements. They should provide their expertise to help you determine the best solutions based on your application. Customization not only ensures that the panels fit perfectly into your project but can also enhance performance and longevity.

wire mesh panel manufacturer

Material Selection

The types of materials used in the production of wire mesh panels can significantly impact their performance. Stainless steel, for example, is often chosen for its rust resistance and strength, making it ideal for outdoor applications. On the other hand, galvanized steel might be selected for its cost-effectiveness and durability in less demanding settings.

Evaluate the manufacturer's sourcing of raw materials. Are they using high-quality inputs that comply with industry standards? The sourcing of materials is as crucial as the manufacturing process itself, as it can determine the overall strength and durability of the finished panels.

Manufacturing Capabilities

Consider the manufacturing capabilities of potential suppliers. Do they have the necessary technology and expertise to produce large volumes without compromising on quality? Factories equipped with modern machinery and skilled workforce generally produce better-quality products more efficiently.

Moreover, assess their lead times and capacity for timely delivery. Unexpected delays can derail project timelines, so selecting a manufacturer who understands the importance of punctuality can save you significant headaches.

Customer Service and Support

Excellent customer service should never be underestimated. Engaging with a supplier who provides extensive after-sales support, including guidance on installation and maintenance, can enhance your experience. Communication is key; a responsive manufacturer can clarify doubts and offer solutions promptly when challenges arise.

Conclusion

In summary, selecting the right wire mesh panel manufacturer is crucial for ensuring the success of your project. By focusing on quality assurance, customization options, material selection, manufacturing capabilities, and customer service, you can make an informed decision. Taking the time to research and evaluate potential manufacturers will ultimately lead to better products and a more positive overall experience. Quality wire mesh panels can enhance safety, security, and efficiency across many applications, making the choice of manufacturer a decision that should not be taken lightly.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025