-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Pro . 21, 2024 06:44 Back to list

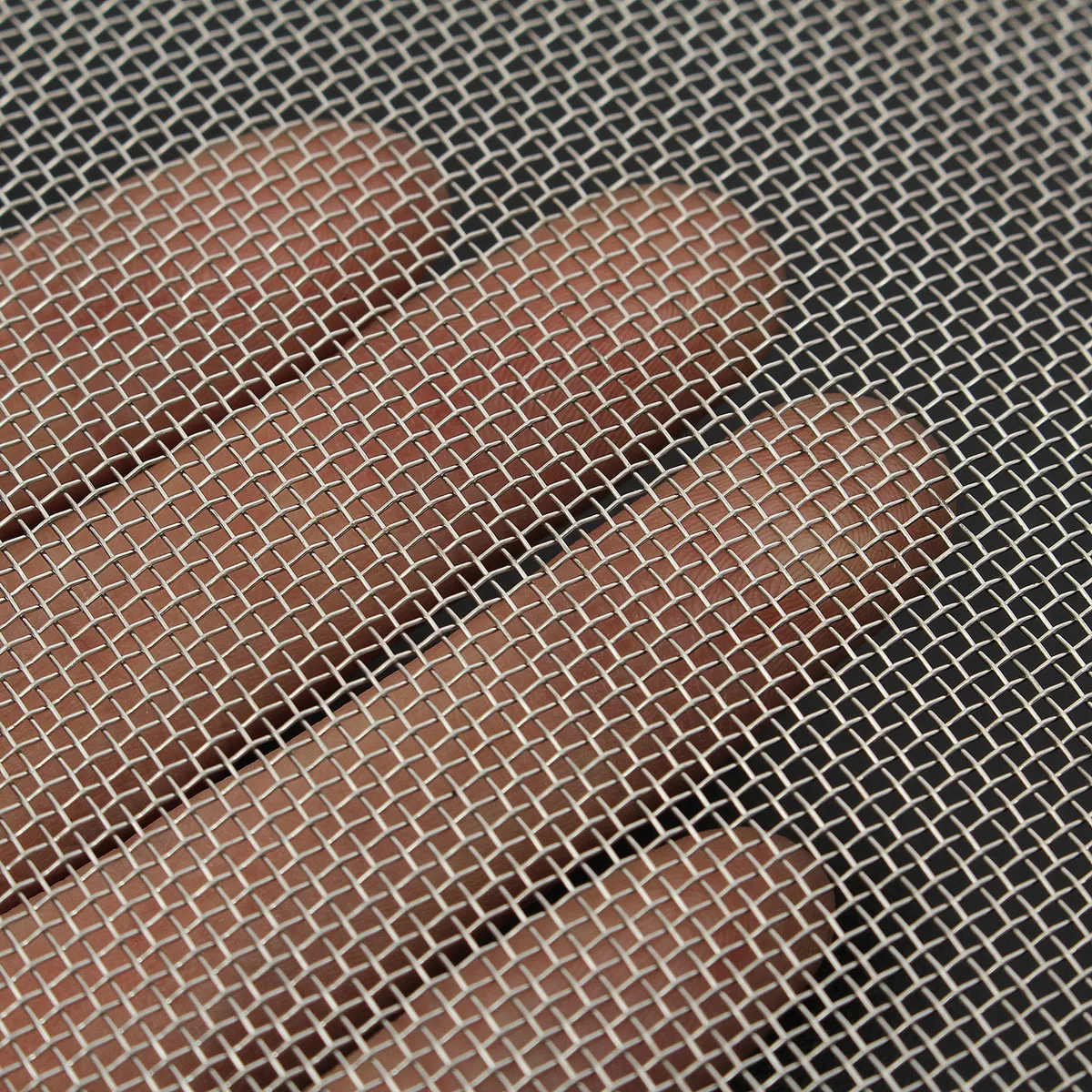

crimped mesh manufacturer

The Importance of Crimped Mesh in Various Industries

In the ever-evolving world of manufacturing and construction, the demand for versatile and durable materials is paramount. Among these materials, crimped mesh has emerged as a favored choice across various industries due to its unique properties and adaptability. Crimped mesh manufacturers play a crucial role in producing this essential product, which finds applications in construction, filtration, agriculture, and more.

What is Crimped Mesh?

Crimped mesh, also known as crimped wire mesh or woven wire mesh, is created by weaving metal wires in a crimped pattern. This distinctive design enhances the strength and stability of the mesh, making it highly resistant to wear and tear. The crimping process involves bending the wire at regular intervals, which not only increases its structural integrity but also allows for better spacing between the wires. This makes crimped mesh ideal for a variety of applications that require both durability and flexibility.

Applications of Crimped Mesh

The versatility of crimped mesh means it can be used in a wide range of industries

1. Construction and Architecture Crimped mesh is widely used in construction for reinforcement, grating, and barriers. It can be found in concrete reinforcement, where it adds structural support and prevents cracking. Additionally, architects often utilize crimped mesh for aesthetic purposes in facades and decorative elements.

2. Filtration In the filtration industry, crimped mesh serves an essential function. Its precise opening sizes allow for effective separation of solids from liquids or gases, making it ideal for water treatment plants, chemical processing, and food production facilities. Manufacturers can customize the mesh size and crimp pattern to meet specific filtration needs.

crimped mesh manufacturer

3. Agriculture Farmers use crimped mesh for various agricultural applications, including fencing for livestock and protecting crops from pests. The durability of crimped mesh ensures a long-lasting solution that can withstand harsh weather conditions and provide effective barriers.

4. Mining and Quarrying In the mining sector, crimped mesh is crucial for screening materials and separating valuable resources from waste. Its robustness can handle heavy-duty applications, making it a reliable choice for screening plants and processing equipment.

5. Industrial Applications Many manufacturers use crimped mesh in their machinery and equipment for safety and efficiency. As protective grates or guards, crimped mesh can prevent accidents while ensuring that machinery operates smoothly.

The Role of Crimped Mesh Manufacturers

The importance of crimped mesh has led to an increase in demand, making crimped mesh manufacturers vital to supply chains across industries. These manufacturers not only produce crimped mesh in various sizes and specifications but also innovate in terms of materials used. Stainless steel, galvanized steel, and other alloys are commonly employed to enhance corrosion resistance and longevity.

Moreover, quality assurance is critical in the production process. Reputable manufacturers adhere to strict quality control standards to ensure that the crimped mesh they produce meets industry requirements. This includes regular testing of tensile strength, corrosion resistance, and dimensional accuracy.

Conclusion

Crimped mesh is a multifaceted product that plays an essential role in diverse industrial applications, thanks to its unique properties and reliability. As the demand for high-quality crimped mesh continues to grow, manufacturers are constantly innovating and improving their production processes to keep up with market needs. Their commitment to quality and adaptability ensures that crimped mesh remains a valuable resource across construction, filtration, agriculture, mining, and beyond. Whether for practical applications or aesthetic enhancements, the role of crimped mesh and its manufacturers cannot be overstated in today's industrial landscape.

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025