-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Bře . 07, 2025 05:22 Back to list

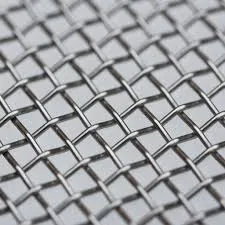

Crimped Wire Mesh

High-quality crimped woven mesh is an essential material finding extensive use in various industrial applications. Its exceptional durability, strength, and versatility render it indispensable in sectors ranging from construction to mining, filtering to screening, and even in artistic endeavors. To comprehensively understand the intricate world of crimped woven mesh, one must appreciate not only its applications but also the meticulous craftsmanship and expertise that go into its production.

Moreover, the expertise extends beyond production to encompass tailored solutions for specific needs. Manufacturers who excel in the production of crimped woven mesh often offer customization options, allowing clients to choose the wire diameter, mesh opening size, and crimp style that best suits their application. This bespoke approach ensures that specific industrial requirements are met with precision, providing businesses with a product that perfectly aligns with their operational demands. The authority of leading crimped woven mesh producers is further established through certifications and compliance with international standards. Many reputable manufacturers boast credentials from recognized certifying bodies, adding a layer of credibility and assurance of quality to their products. This adherence not only guarantees the performance of the mesh in various applications but also emphasizes the commitment of these manufacturers to excellence and reliability. Ultimately, the trustworthiness of high-quality crimped woven mesh lies in its proven track record across myriad industries. Businesses and professionals have long relied on its performance, supported by testimonials and case studies showcasing successful applications and long-term benefits. Over time, partnerships with experts in the field foster a cycle of constant innovation and improvement, ensuring the products evolve to meet ever-changing industry requirements. In conclusion, high-quality crimped woven mesh is a testament to the beauty of precision engineering and dedication to excellence. Its profound impact across industries underscores the importance of choosing a trusted manufacturer capable of delivering not only a product but a promise of quality, durability, and tailored expertise. This attention to detail and commitment to superior craftsmanship are what set high-quality crimped woven mesh apart, making it an invaluable asset in any demanding application.

Moreover, the expertise extends beyond production to encompass tailored solutions for specific needs. Manufacturers who excel in the production of crimped woven mesh often offer customization options, allowing clients to choose the wire diameter, mesh opening size, and crimp style that best suits their application. This bespoke approach ensures that specific industrial requirements are met with precision, providing businesses with a product that perfectly aligns with their operational demands. The authority of leading crimped woven mesh producers is further established through certifications and compliance with international standards. Many reputable manufacturers boast credentials from recognized certifying bodies, adding a layer of credibility and assurance of quality to their products. This adherence not only guarantees the performance of the mesh in various applications but also emphasizes the commitment of these manufacturers to excellence and reliability. Ultimately, the trustworthiness of high-quality crimped woven mesh lies in its proven track record across myriad industries. Businesses and professionals have long relied on its performance, supported by testimonials and case studies showcasing successful applications and long-term benefits. Over time, partnerships with experts in the field foster a cycle of constant innovation and improvement, ensuring the products evolve to meet ever-changing industry requirements. In conclusion, high-quality crimped woven mesh is a testament to the beauty of precision engineering and dedication to excellence. Its profound impact across industries underscores the importance of choosing a trusted manufacturer capable of delivering not only a product but a promise of quality, durability, and tailored expertise. This attention to detail and commitment to superior craftsmanship are what set high-quality crimped woven mesh apart, making it an invaluable asset in any demanding application.

Next:

Latest news

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025