-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Pro . 11, 2024 10:50 Back to list

High Strength Wire for Durable Fencing Solutions from Leading Manufacturers

High Tensile Fence Wire Factories An Overview

High tensile fence wire has become an essential component in livestock management, agricultural practices, and industrial applications. The unique properties of high tensile wire, including its strength, durability, and resistance to environmental factors, make it a preferred choice for fencing solutions across various sectors. This article delves into the world of high tensile fence wire factories, exploring their significance, manufacturing processes, and the benefits they offer to consumers.

The Importance of High Tensile Fence Wire

High tensile fence wire is characterized by its ability to withstand greater loads and pressure compared to traditional barbed wire or low tensile wire. This makes it particularly suitable for fencing large areas, such as farms, ranches, and industrial sites. Farmers and ranchers favor high tensile wire because it not only provides secure containment of livestock but also reduces the need for frequent repairs and replacements, ultimately leading to lower maintenance costs.

Moreover, high tensile fence wire is designed to resist corrosion and rust, thanks to protective coatings, such as galvanized steel. This resilience ensures that fences maintain their structural integrity and visual appeal over time, even in harsh weather conditions. As a result, high tensile wire fences are favored for their longevity and effectiveness.

Manufacturing Processes From Raw Material to Finished Product

The production of high tensile fence wire takes place in specialized factories equipped with advanced machinery and technology

. The manufacturing process includes several stages1. Material Selection The primary raw material for high tensile fence wire is steel, known for its strength and durability. Factories typically use high carbon steel, which undergoes a specific treatment process to enhance its tensile strength. This initial selection is crucial, as the quality of the raw material directly influences the final product's performance.

2. Drawing and Stranding The selected steel undergoes a drawing process, where it is pulled through a series of dies to reduce its diameter and increase its length. This process strengthens the wire significantly. In some cases, multiple strands of wire are combined to create a thicker and stronger fencing solution.

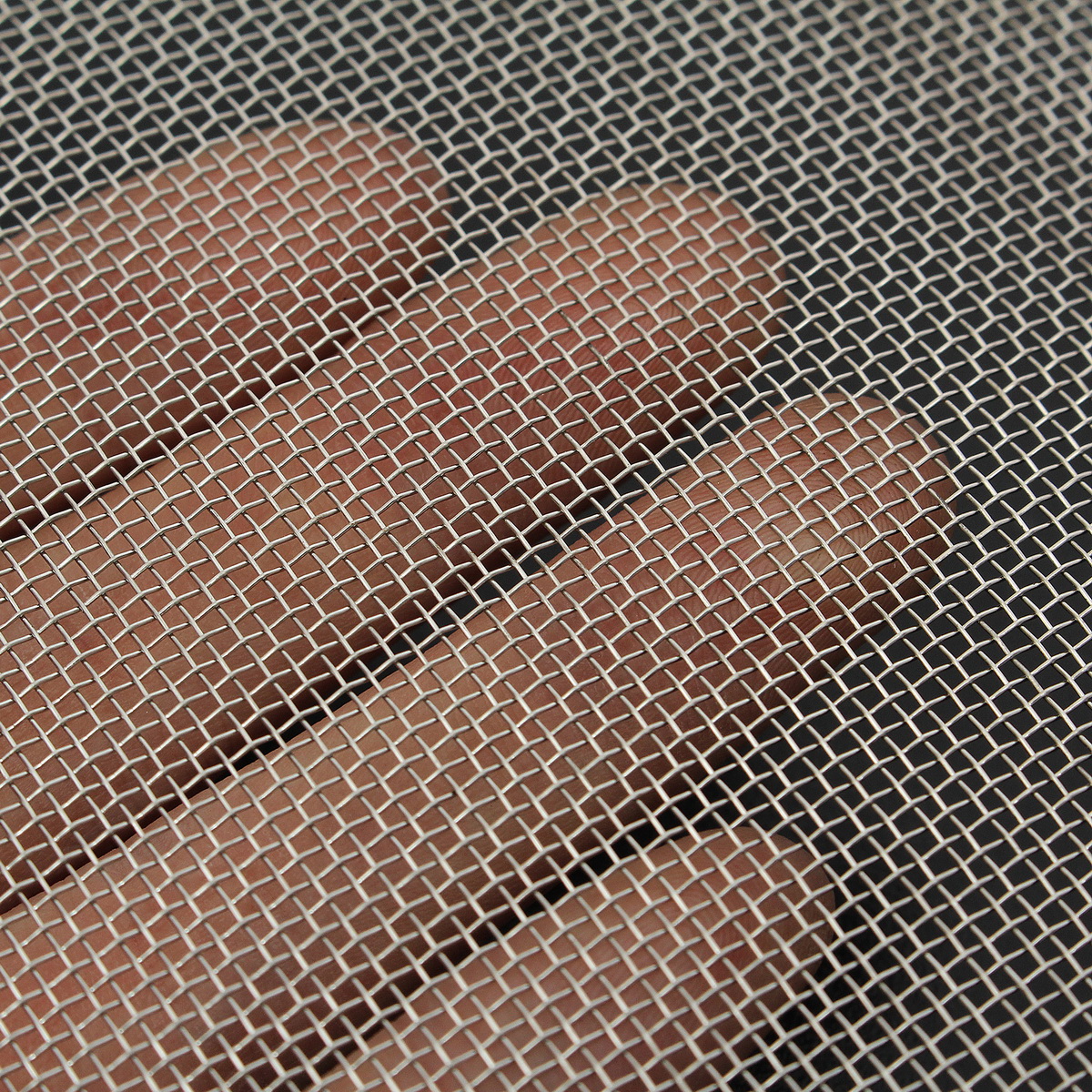

3. Galvanization To prevent corrosion, the drawn wire is often galvanized. This involves coating the wire with a layer of zinc, which acts as a protective barrier against moisture and environmental elements. Factories may utilize either hot-dip galvanization or electro-galvanization, depending on the desired level of protection and production efficiency.

high tensile fence wire factories

4. Spooling and Packaging The finished wire is then wound onto spools or coils for easy transport and installation. Factories ensure that the spooling is done correctly to avoid tangling and damage, ensuring that the product reaches consumers in excellent condition.

5. Quality Control Before the wire leaves the factory, it undergoes rigorous quality control tests. These tests evaluate the tensile strength, coating thickness, and overall durability of the product. This step ensures that only the highest quality wire is available in the market, meeting the standards set by industry regulations.

Benefits of Buying from High Tensile Fence Wire Factories

Purchasing high tensile fence wire directly from factories offers several advantages for consumers

1. Cost-Effectiveness Buying in bulk from manufacturers often leads to significant cost savings. Consumers can take advantage of lower prices and better deals when purchasing directly from factories.

2. Custom Options Many factories offer customization options to meet specific needs, such as varying wire thickness or lengths. This flexibility is particularly beneficial for large-scale agricultural operations or unique industrial applications.

3. Quality Assurance Dealing directly with manufacturers allows consumers to request quality assurance information and product certifications. This is crucial for ensuring that the wire meets the required industry standards and is reliable for long-term use.

4. Direct Support Purchasing from factories often comes with direct customer support. This support can be invaluable for troubleshooting, installation guidance, and any follow-up service needed after purchase.

Conclusion

High tensile fence wire factories play a vital role in providing effective fencing solutions for a wide range of applications. With their advanced manufacturing processes, commitment to quality, and the numerous benefits they offer, these factories are key players in the agricultural and industrial sectors. For those in need of reliable and durable fencing, investing in high tensile fence wire from reputable factories promises a long-lasting solution that stands the test of time. Whether for livestock management or securing industrial premises, high tensile fence wire remains a preferred choice for its unmatched strength and reliability.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025