-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Lis . 22, 2024 21:14 Back to list

perforated metal mesh sheet factories

The Rise of Perforated Metal Mesh Sheet Factories A Gateway to Innovation and Efficiency

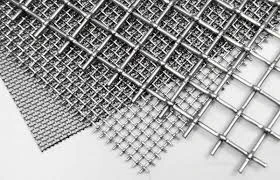

In recent years, the demand for perforated metal mesh sheets has surged, driven by their diverse applications across various industries. These sheets, characterized by their unique patterns of holes punched into a solid metal substrate, offer structural integrity combined with aesthetic appeal. This article explores the significant role of perforated metal mesh sheet factories in meeting this demand and driving innovation.

Perforated metal sheets are used extensively in architecture, automotive, aerospace, and industrial sectors. Their applications range from decorative wall panels to functional components such as filters and heat exchangers. As construction and manufacturing sectors continue to evolve, so does the technology behind perforated metal sheets. Factories specializing in this product are at the forefront of innovation, utilizing advanced machinery and techniques to improve production efficiency and product quality.

One of the key advantages of perforated metal mesh is its versatility. Factories can customize the size, shape, and arrangement of holes according to client specifications. This adaptability is particularly appealing to architects and designers who seek unique solutions to modern design challenges. By offering a range of materials, including stainless steel, aluminum, and copper, these factories cater to diverse aesthetic and functional needs.

perforated metal mesh sheet factories

Sustainability is another significant trend driving the growth of perforated metal mesh sheet factories. Many manufacturers are adopting eco-friendly practices, such as recycling metal waste and minimizing energy consumption during the production process. The inherent durability of metal also contributes to sustainability, as perforated sheets often outlast their non-metal counterparts, reducing the need for frequent replacements.

Moreover, advancements in technology have facilitated the rise of intelligent manufacturing practices in these factories. Automated systems and CNC (computer numerical control) machinery enhance precision and speed in the production of perforated sheets. These technological enhancements enable factories to scale operations, reduce labor costs, and maintain consistent quality in their products.

The global landscape of perforated metal mesh sheet factories is constantly evolving, with many companies expanding their services to cater to international markets. This globalization fosters competition and drives innovation, encouraging factories to improve their offerings continually. Collaborative efforts between manufacturers, designers, and end-users are becoming more common, leading to the development of innovative products that meet specific needs across various sectors.

In conclusion, perforated metal mesh sheet factories play a pivotal role in the intersection of innovation, sustainability, and design. Their ability to produce customized solutions positions them as invaluable partners in numerous industries. As the demand for these products continues to grow, the factories will undoubtedly evolve to meet new challenges, adopting advanced technologies and sustainable practices that benefit both their clients and the environment. The future of perforated metal mesh sheets looks promising, with endless possibilities for creativity and efficiency in both industrial and architectural applications.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025