-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Led . 31, 2025 03:14 Back to list

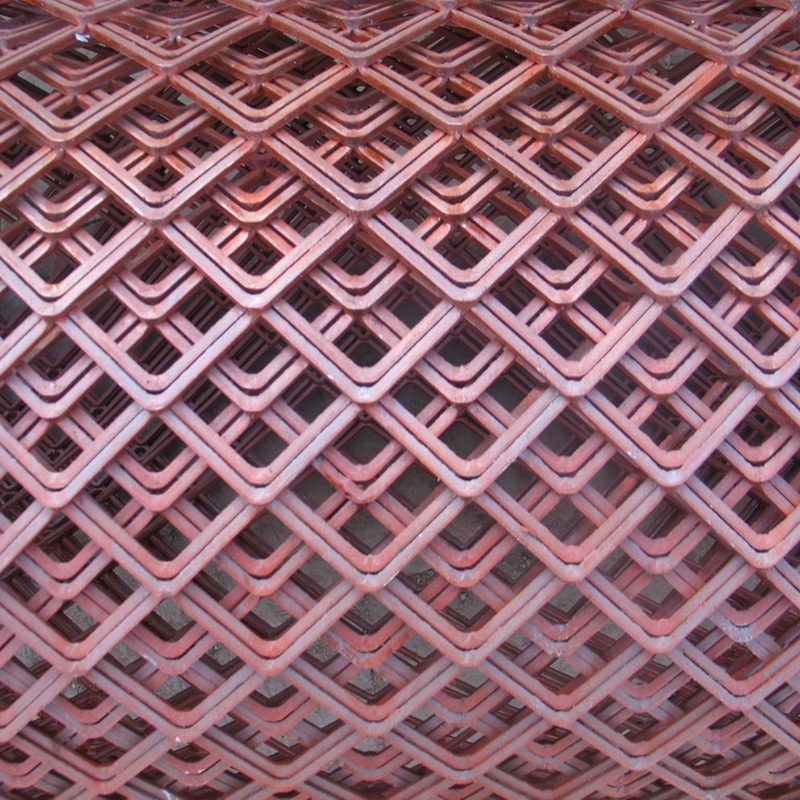

pvc coated welded wire mesh

PVC coated steel wire has revolutionized multiple industries with its robust, durable, and versatile characteristics. Its application ranges from agriculture to construction, impacting sectors with significant reliability and efficiency. The fusion of steel's strength with PVC's protective versatility offers unparalleled product advantages.

From a practical, hands-on perspective, working with PVC coated steel wire brings several advantages in installation processes as well. Unlike non-coated wires, these suffer less tangling and knotting, reducing waste and time during setup. Installers appreciate the reduced wire memory, allowing for straighter and more secure lines when laid out, which translates into higher quality and less manual adjustment. Safety and environmental factors are increasingly important, and PVC coated steel wire ticks these boxes effectively. PVC's non-toxic nature once cured and the recyclability of steel contribute to a product with a minimal environmental footprint. In contexts where safety is paramount, such as playgrounds or residential fencing, the PVC coating provides a buffer reducing sharpness that might otherwise pose a risk. Industry expertise continues to evolve around these wires, with innovations focusing on enhancing coating technologies for even greater UV resistance, and chemical durability. Manufacturers offer extensive technical support and guidance, ensuring optimal material choice depending on specific project requirements. Trustworthiness in selecting PVC coated steel wire suppliers should also be considered, where established brands provide comprehensive certification and testing documentation confirming product quality. In summary, the adoption of PVC coated steel wire supports not only practical outcomes in terms of durability and functionality but aligns with broader goals of innovation, safety, and sustainability. For industries striving for excellence in their structural components, this material comes with a promise of reliability backed by expert evidence and user satisfaction across numerous applications. As technologies advance, embracing new standards in preparation, application, and end-use will further cement the position of PVC coated steel wire as a material of choice in both current and futuristic applications.

From a practical, hands-on perspective, working with PVC coated steel wire brings several advantages in installation processes as well. Unlike non-coated wires, these suffer less tangling and knotting, reducing waste and time during setup. Installers appreciate the reduced wire memory, allowing for straighter and more secure lines when laid out, which translates into higher quality and less manual adjustment. Safety and environmental factors are increasingly important, and PVC coated steel wire ticks these boxes effectively. PVC's non-toxic nature once cured and the recyclability of steel contribute to a product with a minimal environmental footprint. In contexts where safety is paramount, such as playgrounds or residential fencing, the PVC coating provides a buffer reducing sharpness that might otherwise pose a risk. Industry expertise continues to evolve around these wires, with innovations focusing on enhancing coating technologies for even greater UV resistance, and chemical durability. Manufacturers offer extensive technical support and guidance, ensuring optimal material choice depending on specific project requirements. Trustworthiness in selecting PVC coated steel wire suppliers should also be considered, where established brands provide comprehensive certification and testing documentation confirming product quality. In summary, the adoption of PVC coated steel wire supports not only practical outcomes in terms of durability and functionality but aligns with broader goals of innovation, safety, and sustainability. For industries striving for excellence in their structural components, this material comes with a promise of reliability backed by expert evidence and user satisfaction across numerous applications. As technologies advance, embracing new standards in preparation, application, and end-use will further cement the position of PVC coated steel wire as a material of choice in both current and futuristic applications.

Next:

Latest news

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025