-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Pro . 10, 2024 20:41 Back to list

PVC Coated Welded Wire Mesh Panel Manufacturing Supplier

The Importance of PVC Welded Wire Mesh Panels An Overview of Manufacturing Processes

In today’s industrial world, PVC welded wire mesh panels have become a vital component in various applications ranging from construction to agriculture. These panels are not only known for their strength and durability but also for their versatility and cost-effectiveness. In this article, we will explore the manufacturing processes of PVC welded wire mesh panels, their applications, and the advantages they offer.

Understanding PVC Welded Wire Mesh Panels

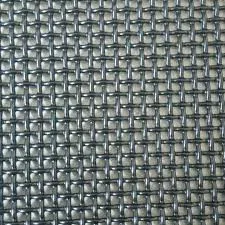

PVC welded wire mesh panels are made from high-quality steel wires that are welded together at intersections. The structure is then coated with polyvinyl chloride (PVC) which offers enhanced protection against rust and corrosion. This makes PVC welded wire mesh an ideal choice for outdoor and indoor applications that demand resilience under various environmental conditions.

Manufacturing Process

The production of PVC welded wire mesh panels involves several key steps

1. Wire Drawing Initially, steel wires are drawn from larger coils into thinner, more manageable strands. The diameter of the wires can vary depending on the intended use of the mesh panels.

2. Welding The drawn wires are arranged in a grid pattern and welded at each intersection. This is done using automated welding machines that ensure a consistent and sturdy connection. The welding process is crucial as it determines the overall strength of the mesh panels.

3. Galvanization (Optional) For additional protection against corrosion, the welded wire mesh can be galvanized. This involves coating the mesh with zinc to create a barrier that prevents rusting.

4. PVC Coating After welding or galvanization, the panels are coated with PVC. This can be done through methods such as dipping or spraying. The coating not only enhances the aesthetic appeal of the mesh but also adds an extra layer of protection, especially in harsh weather conditions.

5. Cutting and Packing Once the panels have been coated and dried, they are cut to desired sizes and packed for shipment. Quality checks are conducted to ensure they meet industry standards.

Applications of PVC Welded Wire Mesh Panels

pvc welded wire mesh panel factory

PVC welded wire mesh panels are highly versatile and find applications across various sectors, including

- Construction Often used as reinforcement in concrete structures, these panels provide strength and support, allowing for safer and more durable constructions. - Agriculture Farmers widely use these panels for fencing and enclosures, helping to keep livestock safe and secure while also protecting crops from pests.

- Industrial Uses In warehouses and factories, PVC welded wire mesh can serve as partitioning, storage solutions, and safety barriers, facilitating a more organized and secure workspace.

- Residential Projects Homeowners use these panels for fencing, gardening, and security purposes. The aesthetic variety offered by different colors of PVC coatings allows clients to match their home’s design seamlessly.

Advantages of PVC Welded Wire Mesh Panels

1. Durability The combination of steel and PVC provides excellent resistance to wear, tear, and environmental damage, ensuring a long lifespan. 2. Low Maintenance Owing to their corrosion-resistant properties, PVC welded wire mesh panels require minimal maintenance when compared to traditional fencing solutions.

3. Aesthetic Appeal Available in various colors, these panels can enhance the visual appeal of any space while offering the same level of security and functionality.

4. Cost-Effectiveness With their longevity and minimal upkeep costs, PVC welded wire mesh panels are a cost-effective solution in the long run.

5. Customizability Manufacturers can easily customize the size, shape, and coating of the panels based on client specifications, ensuring that each product meets the unique needs of its application.

Conclusion

PVC welded wire mesh panels represent a fusion of functionality and durability, making them an indispensable element in multiple industries. As the focus on quality and efficiency grows, the demand for these panels is likely to increase. Understanding their manufacturing processes, applications, and benefits enables businesses and consumers to make informed decisions that lead to optimized usage and satisfaction. Investing in PVC welded wire mesh panels is not just practical; it's a step towards ensuring security and efficiency in various applications.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025