-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Pro . 04, 2024 15:10 Back to list

Sand Screen Mesh Suppliers for Enhanced Filtration Solutions in Industrial Applications

The Evolution and Importance of Sand Screen Mesh Manufacturers

In various industries, particularly in oil and gas, mining, and construction, the significance of effective filtration solutions cannot be overstated. Sand screen mesh manufacturers play a crucial role in providing essential products that ensure efficient separation, filtration, and protection processes. Their innovations and technologies contribute significantly to operational efficiency and safety in demanding environments.

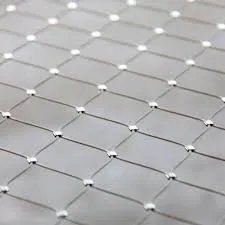

Understanding Sand Screen Mesh

Sand screen mesh is a specific type of filtration material designed to separate sand and other particulates from fluids in various applications. This mesh is typically made from stainless steel, synthetic fibers, or other durable materials constructed to withstand high pressures and corrosive environments. The mesh serves as a barrier, allowing fluids to pass through while trapping unwanted particles.

Applications Across Industries

1. Oil and Gas Industry In oil and gas drilling, sand screen mesh is vital for well completion and production processes. It prevents sand and other particulates from entering the wellbore, thereby protecting pumps and other equipment from damage. This application is critical because any failure to filter efficiently can lead to costly downtime, equipment repairs, and safety hazards.

2. Mining Industry Sand screens are also extensively used in the mining industry, particularly in the extraction of minerals and aggregates. The mesh helps in separating useful minerals from unwanted debris, enhancing the efficiency and quality of mineral processing.

3. Environmental Applications Beyond industrial uses, sand screen mesh can be found in applications relating to environmental protection, such as water treatment. It filters sediments and pollutants from water sources, promoting cleaner water for communities and ecosystems.

Key Features of Sand Screen Mesh

Sand screen mesh products are distinguished by various features and specifications, which make them suitable for specific applications

- Durability Given the harsh conditions they often face, effective sand screens must be made from materials that resist wear and corrosion over time. Stainless steel, for example, is commonly chosen for its excellent resistance to rust and its robust mechanical properties.

sand screen mesh manufacturers

- Mesh Size The size of the openings in sand screen mesh varies depending on the application's requirements. Choosing the right mesh size is crucial as it affects the efficiency of filtration and the amount of fluid that can pass through.

- Design Variability Sand screen meshes come in numerous designs and configurations, such as wedge wire, perforated plates, and synthetic options. Each design has unique attributes suited for different operational needs and fluid properties.

The Role of Manufacturers

The expertise of sand screen mesh manufacturers is crucial in ensuring the reliability and performance of these filtration systems. These manufacturers utilize advanced technologies in fabrication and testing, guaranteeing high-quality products that meet industry standards. Moreover, many manufacturers are increasingly adopting innovative production techniques and materials to enhance the performance of their products.

Manufacturers also provide customized solutions tailored to specific needs, allowing businesses to address unique operational challenges effectively. This flexibility is vital in sectors characterized by rapid technological change and evolving demands.

Sustainability and Future Developments

As industries become more focused on sustainability, sand screen mesh manufacturers are adapting to these changes by developing eco-friendly materials and processes. The exploration of biodegradable options and recycling practices demonstrates a growing commitment to minimizing the environmental footprint of manufacturing operations.

Furthermore, advancements in nanotechnology and materials science are expected to lead to the development of even more efficient filtering solutions. These innovations could enable sand screen meshes to filter out smaller particles and improve flow rates, thereby further enhancing operational efficiency across various sectors.

Conclusion

In summary, sand screen mesh manufacturers play a pivotal role in numerous industries, providing essential products that enhance filtration and separation processes. Their focus on durability, customization, and technological advances ensures that businesses can operate efficiently and safely in challenging environments. As industries move towards greater sustainability and innovation, the importance of these manufacturers will only continue to grow, supporting a future where efficiency and eco-consciousness go hand in hand.

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025