-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Pro . 09, 2024 15:19 Back to list

stainless steel welded wire mesh panel manufacturers

Stainless Steel Welded Wire Mesh Panel Manufacturers

In the contemporary industrial landscape, stainless steel welded wire mesh panels are a key component in various applications, ranging from construction to agriculture and security. Manufacturers of these panels have risen to meet the growing demand, ensuring quality, durability, and functionality. This article sheds light on the significance of stainless steel welded wire mesh panels, the manufacturing process, and the implications for different industries.

Understanding Stainless Steel Welded Wire Mesh

Stainless steel welded wire mesh panels are made from stainless steel wires that are welded together at the intersection points, creating a grid-like structure. This method provides enhanced strength and stability compared to woven wire mesh. The versatility of stainless steel makes it resistant to corrosion, rust, and deformation, thus prolonging the lifespan of the final product.

Applications of Welded Wire Mesh Panels

1. Construction Industry One of the most prominent uses of stainless steel welded wire mesh panels is in the construction sector. These panels serve as reinforcement in concrete, ensuring that buildings and structures are stable and durable. Additionally, they are used in partitioning, fencing, and creating safety barriers.

2. Agricultural Use Farmers utilize welded wire mesh to protect crops from pests and larger animals. It serves as fencing for livestock enclosures and gardens, providing a physical barrier while allowing air, light, and water to penetrate.

3. Security Solutions In terms of security, these mesh panels are commonly used for fencing industrial sites, private properties, and public spaces. Their robust nature makes them an effective deterrent against unauthorized access.

4. Architectural Features Stainless steel welded wire mesh panels have also found their way into architectural designs. They can be used for decorative facades, sunshades, and interior partitions, adding aesthetic appeal while maintaining the structure's functionality.

The Manufacturing Process

The manufacture of stainless steel welded wire mesh panels involves several critical steps

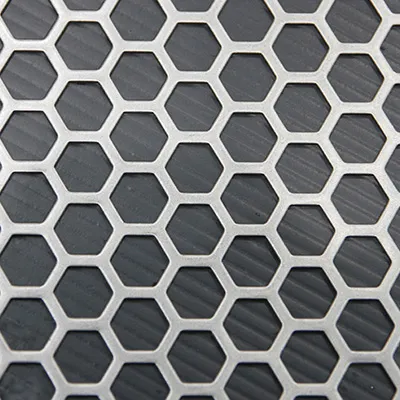

stainless steel welded wire mesh panel manufacturers

1. Material Selection High-quality stainless steel is selected for durability and resistance to environmental factors. Common grades used include 304 and 316 stainless steel, known for their excellent corrosion resistance.

2. Wire Preparation The selected stainless steel wires are cut to the desired lengths and cleaned to remove any surface impurities. This preparation is vital for ensuring strong welds.

3. Welding Process The wires are arranged in a grid pattern, and the intersections are welded using advanced welding techniques. This creates a strong bond between the wires, resulting in a sturdy mesh panel.

4. Finishing After welding, the panels undergo various finishing processes, such as grinding, polishing, and surface treatments, to enhance their appearance and improve resistance to the elements.

5. Quality Control Finally, the panels are subjected to rigorous quality control tests to ensure they meet industry standards. This includes checking for structural integrity, weld strength, and surface finish.

Choosing the Right Manufacturer

When selecting a manufacturer for stainless steel welded wire mesh panels, several factors should be considered

- Experience Look for manufacturers with a solid track record in producing quality products. - Customization Ensure that they can accommodate specific requirements in terms of sizes, shapes, and mesh specifications. - Quality Assurance Inquire about their quality control processes and certifications to ensure compliance with industry standards. - Technical Support Manufacturers that offer technical support can assist customers in selecting the right products for their specific applications.

Conclusion

Stainless steel welded wire mesh panels play a crucial role in various sectors, thanks to their strength, durability, and versatility. As the demand for these products continues to grow, manufacturers must adhere to high standards of quality and innovation to meet the diverse needs of their customers. With the right manufacturer, businesses can obtain reliable mesh solutions tailored to their unique requirements, ensuring long-term satisfaction and performance.

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025