-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Srp . 12, 2024 09:26 Back to list

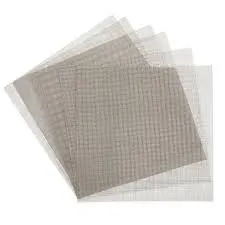

Top Manufacturers of Galvanized Square Wire Netting for Various Applications and Durability

The Importance of Selecting the Right Galvanized Square Wire Netting Manufacturers

When it comes to construction, agriculture, and various industrial applications, galvanized square wire netting plays a critical role. Its durability, corrosion resistance, and versatility make it an essential material for a multitude of projects. However, the quality of the wire netting you use greatly depends on the manufacturer you choose. Therefore, understanding how to select reputable galvanized square wire netting manufacturers is crucial for ensuring the success of your projects.

Understanding Galvanized Square Wire Netting

Galvanized square wire netting is made from high-quality steel wire that has been coated with a layer of zinc to prevent rust and corrosion. This type of netting is characterized by its square mesh design, which allows for effective support and containment, making it suitable for fencing, animal enclosures, and even as reinforcement in construction. The galvanization process protects the wire from harsh environmental elements, thereby extending its lifespan significantly.

Factors to Consider When Choosing Manufacturers

1. Quality of Materials The first consideration when selecting a manufacturer should be the quality of wire they use. High-grade steel is essential for creating strong and durable netting. Reputable manufacturers conduct rigorous quality control assessments to ensure that their products meet industry standards, which ultimately impacts the reliability of the netting.

2. Manufacturing Process Different manufacturers may employ various processes for galvanization. It’s vital to understand whether they use hot-dip galvanization or electro-galvanization. Hot-dip galvanization typically offers a thicker coating, leading to better corrosion resistance, especially in aggressive environments.

galvanized square wire netting manufacturers

3. Customization Options Depending on your project requirements, you may need specific sizes, mesh openings, or additional treatments for the wire netting. Manufacturers who offer customization options can provide tailored solutions that fit your specific needs, ensuring better performance and longevity.

4. Experience and Reputation A manufacturer’s experience in the industry can often be a good indicator of product quality. Look for companies with a solid track record and positive customer reviews. This can provide insights into their reliability, communication, and after-sales support.

5. Certifications and Compliance Ensure that the manufacturer complies with relevant industry standards and holds certifications that guarantee product quality. This can include ISO certifications and compliance with safety regulations, which are critical in assuring the durability and safety of the products.

6. Pricing and Value While cost is an essential factor, it should not compromise quality. Obtain quotes from various manufacturers, but consider the overall value they offer, including quality, customization, and service. Cheaper options may save money initially but can lead to higher costs down the line due to replacements and repairs.

7. Customer Support and Warranty Reliable customer support can make a significant difference in your purchasing experience. A manufacturer offering robust customer service can assist with any inquiries or issues that arise after the purchase. Additionally, a warranty on the wire netting can provide peace of mind, protecting your investment.

Conclusion

Selecting the right galvanized square wire netting manufacturer is essential for ensuring that your projects are both effective and durable. By considering factors such as material quality, manufacturing processes, customization options, experience, and customer support, you can make an informed decision. In doing so, you will not only ensure the success of your current projects but also foster a long-term partnership with a reliable supplier that meets your evolving needs. In a competitive market, prioritizing quality over cost will ultimately lead to safer and more effective applications across various industries.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025