-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Led . 09, 2025 13:56 Back to list

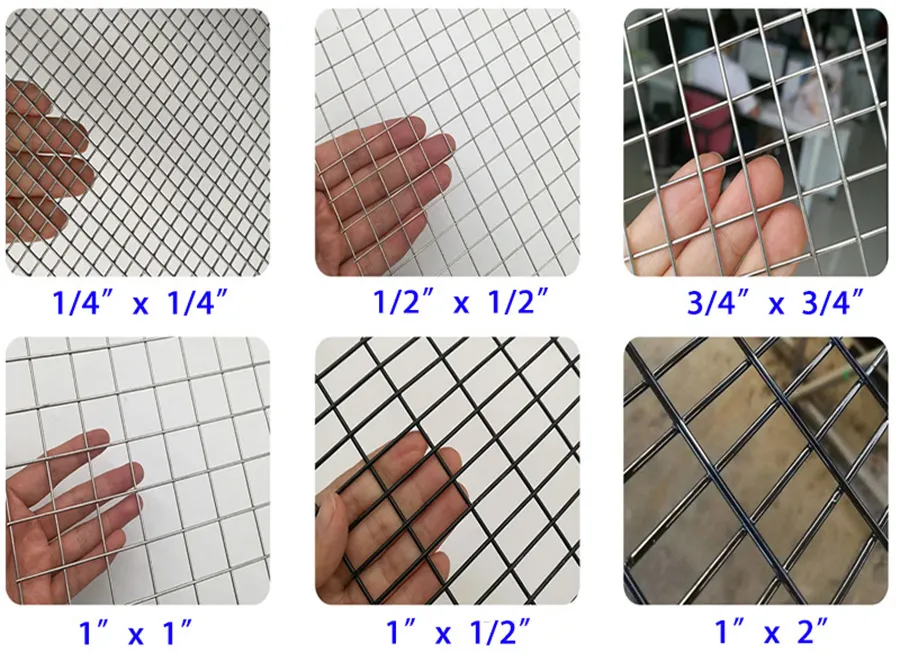

Welded Wire Mesh

Welded wire mesh stands as a fundamental component in various construction and industrial applications, distinguished by its strength, versatility, and reliability. With decades of evolution in its manufacturing process, welded wire mesh has become a trusted solution for reinforcing concrete structures, providing security, and more.

The authoritativeness of welded wire mesh as a preferable material is supported by numerous studies and field tests highlighting its durability and cost-effectiveness. Testimonials from industry professionals further solidify its reputation. Leading construction firms consistently cite it as a preferred material, attributing their choice to the mesh's proven track record in enhancing structural resilience and project longevity. Trust in welded wire mesh is not merely borne out of its physical properties but also its compliance with international standards. Trusted manufacturers ensure that their products meet ASTM, AASHTO, or ISO standards, which are recognized by engineers and builders worldwide. This compliance strengthens the mesh's position as a reliable and safe component in construction projects, instilling confidence among stakeholders. To maximize the benefits of welded wire mesh, selection should be based on specific project requirements, considering factors like wire diameter, spacing, and finish. Consulting with material specialists can provide valuable insights into optimizing mesh selection for efficiency and cost-effectiveness. In conclusion, welded wire mesh continues to be an indispensable material in construction and industrial applications. Its durability, ease of use, and compliance with international standards showcase its unmatched capability. For those invested in building robust, reliable structures, welded wire mesh is not just an option—it is a proven, authoritative solution that embodies both expertise and trustworthiness in modern engineering.

The authoritativeness of welded wire mesh as a preferable material is supported by numerous studies and field tests highlighting its durability and cost-effectiveness. Testimonials from industry professionals further solidify its reputation. Leading construction firms consistently cite it as a preferred material, attributing their choice to the mesh's proven track record in enhancing structural resilience and project longevity. Trust in welded wire mesh is not merely borne out of its physical properties but also its compliance with international standards. Trusted manufacturers ensure that their products meet ASTM, AASHTO, or ISO standards, which are recognized by engineers and builders worldwide. This compliance strengthens the mesh's position as a reliable and safe component in construction projects, instilling confidence among stakeholders. To maximize the benefits of welded wire mesh, selection should be based on specific project requirements, considering factors like wire diameter, spacing, and finish. Consulting with material specialists can provide valuable insights into optimizing mesh selection for efficiency and cost-effectiveness. In conclusion, welded wire mesh continues to be an indispensable material in construction and industrial applications. Its durability, ease of use, and compliance with international standards showcase its unmatched capability. For those invested in building robust, reliable structures, welded wire mesh is not just an option—it is a proven, authoritative solution that embodies both expertise and trustworthiness in modern engineering.

Next:

Latest news

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025