-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dez . 15, 2024 13:38 Back to list

barbed wire rolls factories

The Production and Importance of Barbed Wire Rolls in Modern Industries

Barbed wire, a crucial innovation since its inception in the late 19th century, serves a variety of applications, from agricultural fencing to securing military installations. The factories that produce barbed wire rolls play a vital role in ensuring the availability and quality of this essential product, catering to diverse sectors and needs.

The Manufacturing Process

The production of barbed wire involves a sophisticated manufacturing process. Factories typically begin with high-quality steel wire rods, which are then drawn down to the desired diameter. The next step is the creation of the barbed points; this is achieved by twisting wire strands to form barbs at regular intervals. The barbs are secured using precise machinery, ensuring consistency in spacing and attachment strength. Following this, the barbed wire is either galvanized or coated with other protective layers to enhance durability and resistance to corrosion. Quality control is a crucial aspect of production, where each roll undergoes rigorous testing to meet industry standards.

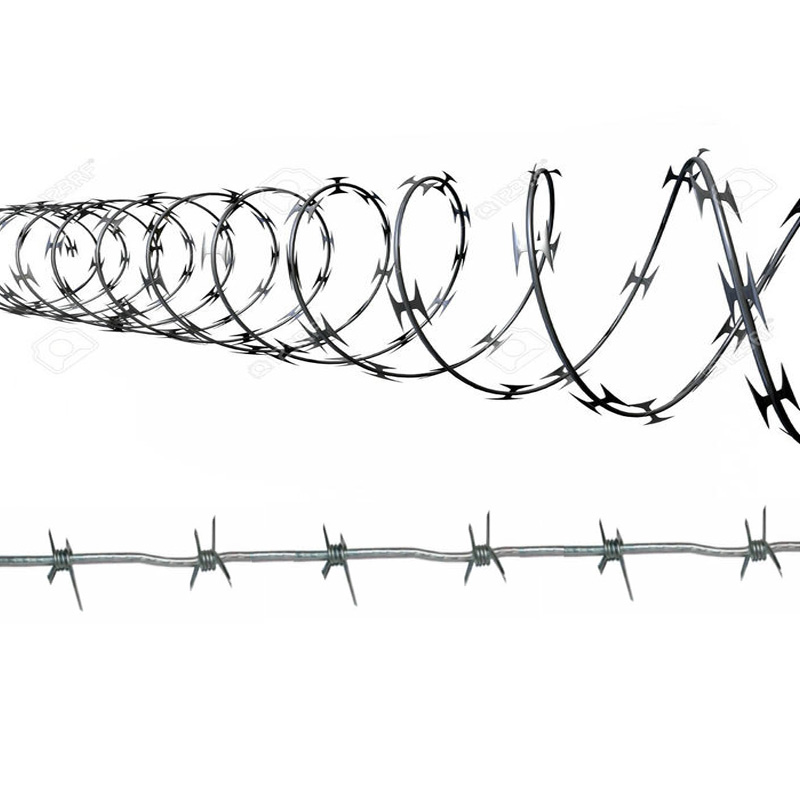

Types of Barbed Wire

There are various types of barbed wire rolls available, tailored for specific applications. Standard types include single-strand barbed wire, which is commonly used in agricultural settings for fencing livestock, and double-strand barbed wire, offering enhanced security and strength for commercial and residential properties. There are also specialized varieties, such as razor wire, designed to provide higher security for prisons, military bases, and other sensitive locations. These variations highlight the adaptability of barbed wire, allowing it to meet the unique requirements of different environments.

barbed wire rolls factories

Applications of Barbed Wire

The versatility of barbed wire rolls makes them invaluable across numerous industries. In agriculture, they help keep livestock contained and protect crops from wildlife. In residential areas, they provide an additional layer of security to fences, deterring intruders. Moreover, barbed wire is extensively used in military and industrial applications, where it serves as a formidable barrier against unauthorized access. The combination of effectiveness and cost-efficiency has solidified barbed wire's status as an essential component in security measures worldwide.

Environmental Considerations

While barbed wire is vital for security and agricultural purposes, the manufacturing process is not without its environmental concerns. Factories must adopt sustainable practices to minimize waste and energy consumption. The use of recyclable materials and the implementation of eco-friendly manufacturing techniques can significantly reduce the ecological footprint of barbed wire production. Emerging technologies in recycling steel and innovations in materials science are paving the way for a more sustainable future in this industry.

Conclusion

Barbed wire rolls remain an indispensable element of modern society, with a manufacturing sector that continues to adapt to the evolving needs of consumers. The factories responsible for producing these essential products play a significant role in ensuring quality, availability, and sustainability. As industries grow and the demand for effective security solutions rises, the importance of innovations in barbed wire production will only increase. As such, stakeholders within this sector must remain committed to balancing efficiency, environmental responsibility, and the needs of their customers, ensuring that barbed wire remains a practical, reliable solution for fencing and security in the years to come.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025