-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dez . 31, 2024 01:40 Back to list

crimped woven mesh manufacturers

Understanding Crimped Woven Mesh A Guide to Manufacturers

Crimped woven mesh has increasingly gained prominence across various industries due to its unique properties and versatility. As industries evolve, the demand for high-quality mesh products continues to rise, prompting manufacturers to innovate and adapt their processes. This article explores the characteristics of crimped woven mesh, its applications, and key considerations when selecting manufacturers.

What is Crimped Woven Mesh?

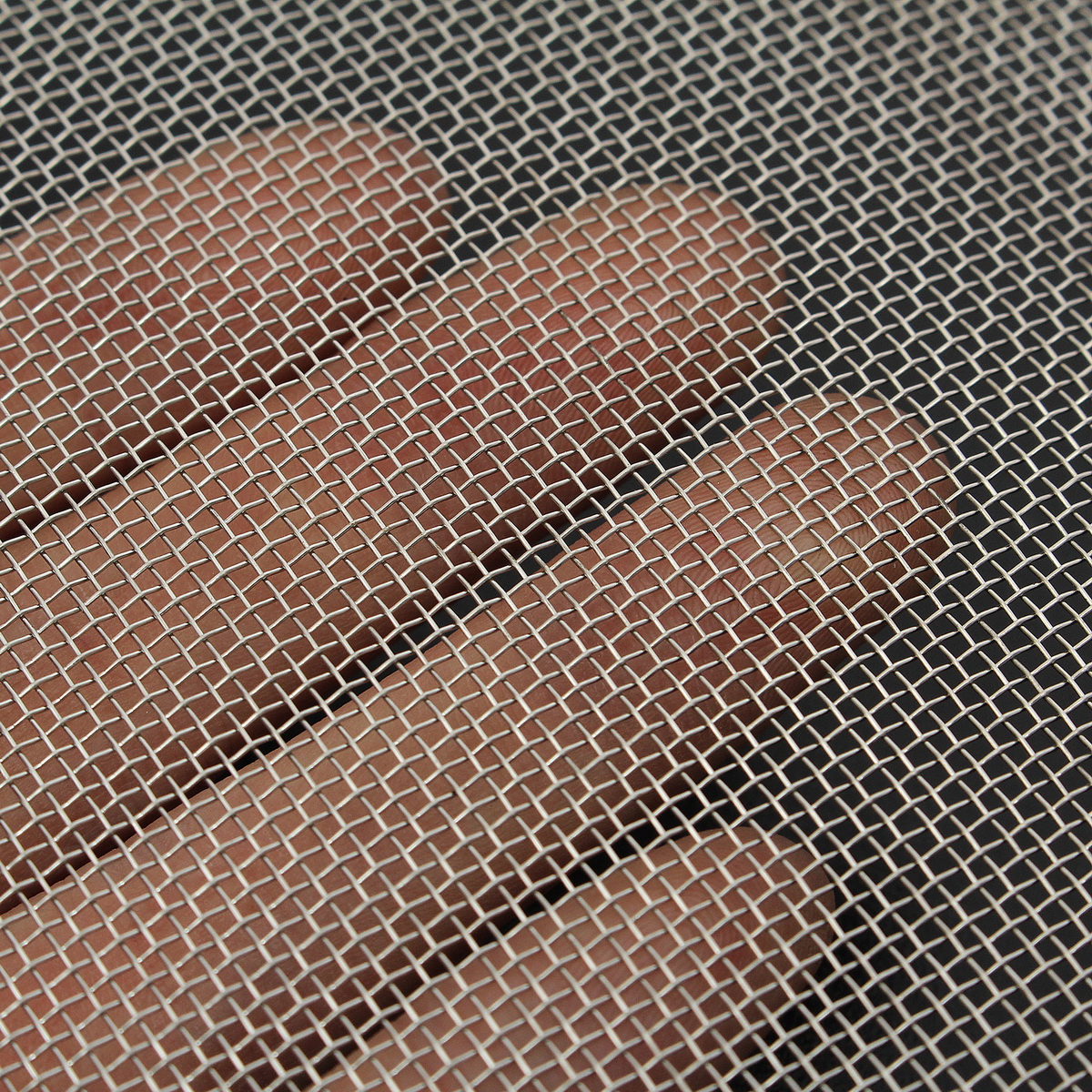

Crimped woven mesh is a type of wire mesh that is produced by weaving crimped wires together, forming a distinctive pattern that enhances its strength and durability. The crimping process involves bending the wires in a systematic manner before weaving, creating a more robust structure compared to standard woven mesh. Crimped wires provide added grip during weaving, ensuring that the mesh remains stable and retains its shape under varying stress conditions.

The manufacturing of crimped mesh utilizes different types of materials, including stainless steel, galvanized steel, and various alloys. Each material contributes specific characteristics, such as corrosion resistance, tensile strength, and temperature tolerance, thus making the mesh suitable for diverse applications.

Applications of Crimped Woven Mesh

The versatility of crimped woven mesh allows it to be used in numerous sectors

1. Mining and Mineral Processing In the mining industry, crimped woven mesh is often employed for screening purposes. It effectively separates different sizes of materials, such as ores and minerals, ensuring optimal efficiency in processing.

2. Construction and Architecture Many builders and architects use crimped mesh as reinforcement in concrete structures and facades. Its strength enhances the stability of constructions and contributes to aesthetic designs.

3. Filtration Crimped woven mesh is widely used in filtration systems, such as water treatment plants, oil and gas production, and food processing. Its ability to trap particles while allowing liquids to pass through makes it an ideal choice for various filtration needs.

4. Animal Farming This type of mesh is also utilized in agricultural applications, such as fencing and enclosures for livestock. The durability and resistance to rust ensure the safety and security of animals.

crimped woven mesh manufacturers

5. Home and Garden Crimped woven mesh can also serve decorative purposes in landscaping and garden design, as well as in home security solutions.

Choosing the Right Manufacturer

When it comes to selecting crimped woven mesh manufacturers, several key factors must be taken into consideration

1. Quality Standards It is crucial to ensure that the manufacturer adheres to industry standards and regulations. High-quality materials and production processes lead to better-end products, enhancing performance and lifespan.

2. Customization Options Depending on specific requirements, the ability to customize the mesh dimensions, wire gauges, and crimping patterns should be available. A good manufacturer can provide tailored solutions to meet unique needs.

3. Experience and Reputation Investigate the manufacturer’s industry experience and reputation. Companies with a long history often have the expertise necessary to produce reliable and top-quality products.

4. Technology and Equipment The technology and machinery used in the production process can significantly affect the quality of the mesh. Manufacturers that invest in modern equipment and techniques are likely to produce superior products.

5. Customer Support and Service Good customer support is essential for addressing any concerns during the purchasing process. A manufacturer that is responsive and helpful can make a significant difference in overall satisfaction.

6. Sustainability Practices Consider selecting manufacturers that prioritize eco-friendly practices and sustainable sourcing of materials, contributing to a more sustainable future.

Conclusion

Crimped woven mesh is a remarkable product with an array of applications that cater to various industries. By understanding its characteristics and the factors that contribute to selecting the right manufacturers, businesses can benefit from high-quality mesh products that enhance operational efficiency and meet specific needs. As demand continues to grow, innovation in manufacturing processes will define the future of crimped woven mesh and its applications in our industries.

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025